ZJY-50 Mobile Concrete Batching Plant Product Description

What is a Mobile Concrete Mixing Plant?

Mobile concrete mixing plant is a kind of equipment that can be quickly and easily moved to different construction sites for concrete production. It is a concrete production plant with integrated raw material storage, weighing, conveying, mixing, discharging and fully automatic control system that allows concrete production and supply on site at the construction site, avoiding transportation time and costs. It is identical to the fixed automatic mixing plant in terms of process, operation and maintenance, and has unique features such as flexible movement, quick and easy disassembly, and simple storage and management.

Wide range of applications

As a portable concrete production equipment, the mobile concrete mixing plant is flexible and efficient, so it is widely used in various engineering construction fields. In urban construction, it can be used for the production and supply of concrete for roads, bridges, tunnels, municipal projects and residential construction; in rural construction, it can be used for the production and supply of concrete in agricultural construction, water conservancy projects and rural roads; in the energy industry, it can be used for the production and supply of concrete in the fields of electric power, petroleum, natural gas and mining. The mobile concrete mixing plant has a wide range of applications and can meet the production and supply of concrete of various sizes and demands.

Mobile concrete mixing plant usually consists of the following equipment:

The working principle of portable mobile concrete mixing plant is that the raw materials (cement, stone, sand, water and admixture) are taken out from the storage tank, measured accurately by the weighing system and then sent to the mixer for mixing through the conveying equipment (such as screw conveyor). The mixer is equipped with several mixing shafts with mixing arms and blades, which mix the raw materials thoroughly and discharge the concrete to the transport vehicle through the discharge device. The whole process is controlled and monitored by an automatic control system to ensure the quality and productivity of the concrete. Mobile concrete mixing plants are efficient, portable and reliable, and are widely used in projects that require frequent transfers, short construction cycles and small concrete requirements.

ZOOMJO offers mobile concrete mixing plants in the capacity range of 25-120m³/h and supports customization. There are two types of mobile concrete mixing plants: towed and trailer-mounted. Among them, the chassis of the tractor type contains complete front and rear axles, while the chassis of the trailer type has only the rear axle with the front mounted on the saddle axle of the tractor. Our machines are manufactured in strict accordance with national and international standards, and we test each unit before it leaves the factory.

Mobile concrete mixing plant usually has the following advantages:

1. Portable mobile concrete batching plant can be moved and installed anywhere and anytime, which can meet the concrete needs of different construction sites and improve the construction efficiency.

2. Mobile concrete mixing plant has high efficiency concrete production capacity, which can produce a large amount of concrete in a short time and improve the production efficiency.

3. The mobile cement concrete mixing plant can ensure the uniform mixing and quality of concrete, thus improving the quality of concrete and construction quality.

4. Mobile concrete mixing station is usually equipped with modern control system, which can realize automatic control and remote monitoring, easy management and stable and reliable production process.

Mobile concrete mixing plant and stationary mixing plant are two common types of equipment in concrete production. There are some differences and discrepancies between them in terms of working principle, equipment composition, application scope, advantages and disadvantages, etc.

1. Mobile concrete mixing plant can be moved to the site where concrete production is needed anytime and anywhere, while fixed mixing plant needs to establish a concrete production base near the site, which has certain requirements for the site.

2. Mobile concrete mixing plant is usually small in size and suitable for use in the case of limited space on the construction site, while fixed mixing plant is relatively large and suitable for use in the case of sufficient space on the construction site.

3. The mobile concrete mixing plant can adjust the production capacity according to the needs and has production flexibility, while the production capacity of fixed mixing plant is relatively fixed and not easy to adjust.

4. The investment cost of mobile concrete mixing plant is relatively low, which is suitable for small projects and small and medium-sized enterprises, while the investment cost of fixed mixing plant is high, which is suitable for large projects and enterprises with sufficient capital.

Maintaining the equipment is the key to ensure the normal operation and prolong the service life of the mobile concrete mixing plant. Regular maintenance can reduce equipment failure, improve equipment efficiency and reduce maintenance costs.

1. Regularly clean the interior and exterior of the equipment to ensure that concrete does not accumulate inside the equipment and lubricate the lubrication points on the equipment to ensure the good operation of the equipment.

2. Check the electrical system, hydraulic system and mechanical system of the equipment regularly to ensure the normal operation of all parts of the equipment, find problems and repair them in time.

3. Replace the wearing parts, such as mixer blades, mixing arms, belts, etc., regularly according to the use of the equipment to ensure the stability and reliability of the equipment.

4. For each part of the equipment, follow the instructions in the operation manual for maintenance to ensure the neatness and safety of the equipment.

How to choose mobile concrete mixing plant?

Production capacity: When choosing a concrete mixing plant you should consider the production capacity you need. Select the appropriate production capacity according to the size of your project and the expected production requirements.

Mixing Efficiency: Mixing efficiency is an important consideration because it can directly affect production capacity and concrete quality. A mixing plant with high mixing efficiency can improve concrete production efficiency and quality.

Concrete quality: The quality of concrete is a key factor affecting the quality of the project. Therefore, it is very important to choose a reliable quality mixing plant.

After-sales service: When choosing a mixing plant, you need to consider after-sales service. Choosing a manufacturer with high brand recognition and perfect after-sales service can effectively reduce the after-sales maintenance cost and improve the service life of the equipment.

ZOOMJO was established in 1995, with 28 years of experience, and is the leader of China's machinery industry. It has advanced factory technology and excellent trading ability. We can provide fixed concrete mixing plant, mobile concrete mixing plant, foundationless concrete mixing plant, concrete mixing pump, concrete drag pump, self-unloading concrete mixer, etc. to our customers. Our products have been delivered to more than 105 countries and regions, such as Philippines, Indonesia, Malaysia, Singapore, Sri Lanka, Kazakhstan, Uzbekistan, Russia, Ukraine, Ethiopia, South Africa, Nigeria, Jamaica, Dominica, Australia, etc.

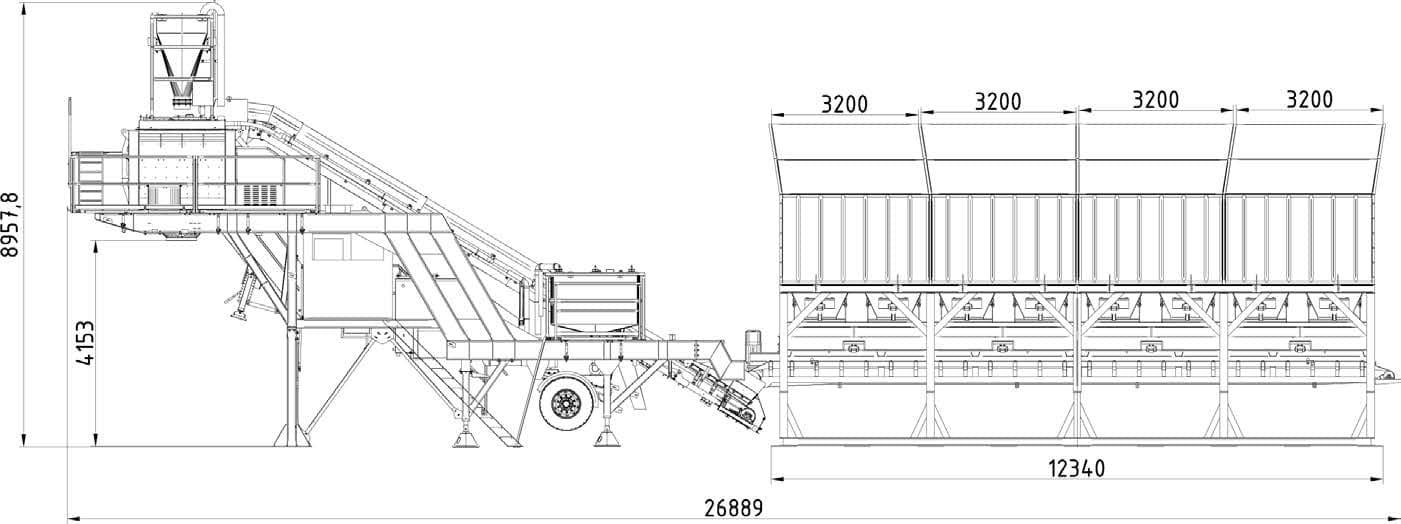

ZJY-50 Mobile Concrete Batching Plant Configuration

| Model | HZS / ZJ25 | HZS / ZJ35 | HZS / ZJ50 | HZS / ZJ60 | HZS / ZJ75 | HZS / ZJ90 | HZS / ZJ120 | HZS / ZJ180 | HZS / ZJ240 |

| Productivity | 25m³/h | 35m³/h | 50m³/h | 60m³/h | 75m³/h | 90m³/h | 120m³/h | 180m³/h | 240m³/h |

| Concrete mixer | JS 500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | JS2000 | JS3000 | JS4000 |

| Mixer discharging capacity | 0.5m³ | 0.75m³ | 1m³ | 1m³ | 1.5m³ | 1.5m³ | 2m³ | 3m³ | 4m³ |

| Feeding Mode | Lift Hopper | Lift Hopper | Lift Hopper | Belt Conveyor | Lift Hopper | Belt Conveyor | Belt Conveyor | Belt Conveyor | Belt Conveyor |

| Aggregate batching machine | PLD800 | PLD1000 | PLD1600 | PLD1600 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Kinds of aggregate | 2/3/4 | 2/3/4 | 3/4 | 3/4/5 | 3/4 | 3/4/5 | 3/4/5 | 3/4/5 | 3/4/5 |

| Max aggregate size | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm |

| Discharging height | 3.8m | 4.1m | 4.1m | 4.1m | 4.1m | 4.1m | 4.3m | 4.3m | 4.3m |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement weighting accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| weight | 10t | 13.5t | 18.5t | 28t | 25t | 40t | 65t | 88t | 98t |

| General installed power | ≈65kw | ≈75kw | ≈100kw | ≈110kw | ≈140kw | ≈160kw | ≈220kw | ≈290kw | ≈340kw |

ZJY-50 Mobile Concrete Batching Plant Related Product

-

HZS / ZJ60 Stationary Concrete Batching PlantThe concrete mixing station is widely used in water conservancy, road and bridge engineering and other proje…

HZS / ZJ60 Stationary Concrete Batching PlantThe concrete mixing station is widely used in water conservancy, road and bridge engineering and other proje… -

HZS / ZJ75 Stationary Concrete Batching PlantZOOMJO HZS75 concrete mixing plant has good mixing performance. The equipment adopts JS1000 spiral double-sh…

HZS / ZJ75 Stationary Concrete Batching PlantZOOMJO HZS75 concrete mixing plant has good mixing performance. The equipment adopts JS1000 spiral double-sh… -

ZJM50 Foundation Free Concrete Batching PlantZJM series concrete batching plant belongs to compulsory and efficiency equipment,It includes JS concrete mi…

ZJM50 Foundation Free Concrete Batching PlantZJM series concrete batching plant belongs to compulsory and efficiency equipment,It includes JS concrete mi…

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська