HZS / ZJ75 Stationary Concrete Batching Plant Product Description

What is a stationary concrete plant?

A stationary concrete plant is a conventional concrete production facility, also known as a stationary concrete mixing plant. This type of plant is typically used to produce large quantities of concrete for construction, road building and other infrastructure projects. The design of stationary concrete plants can be customized to suit different production requirements and site conditions.

Stationary concrete mixing plants can be widely used in construction sites, water conservancy projects, road construction and other fields. In construction sites, stationary concrete mixing plants can be used to produce various kinds of concrete, such as reinforced concrete, precast concrete, etc., to meet the needs of different projects. In water conservancy projects, stationary concrete mixing plant can produce various kinds of concrete, such as cement concrete, piled concrete, etc. In road construction, stationary concrete mixing plant can produce all kinds of concrete, such as asphalt concrete, etc.

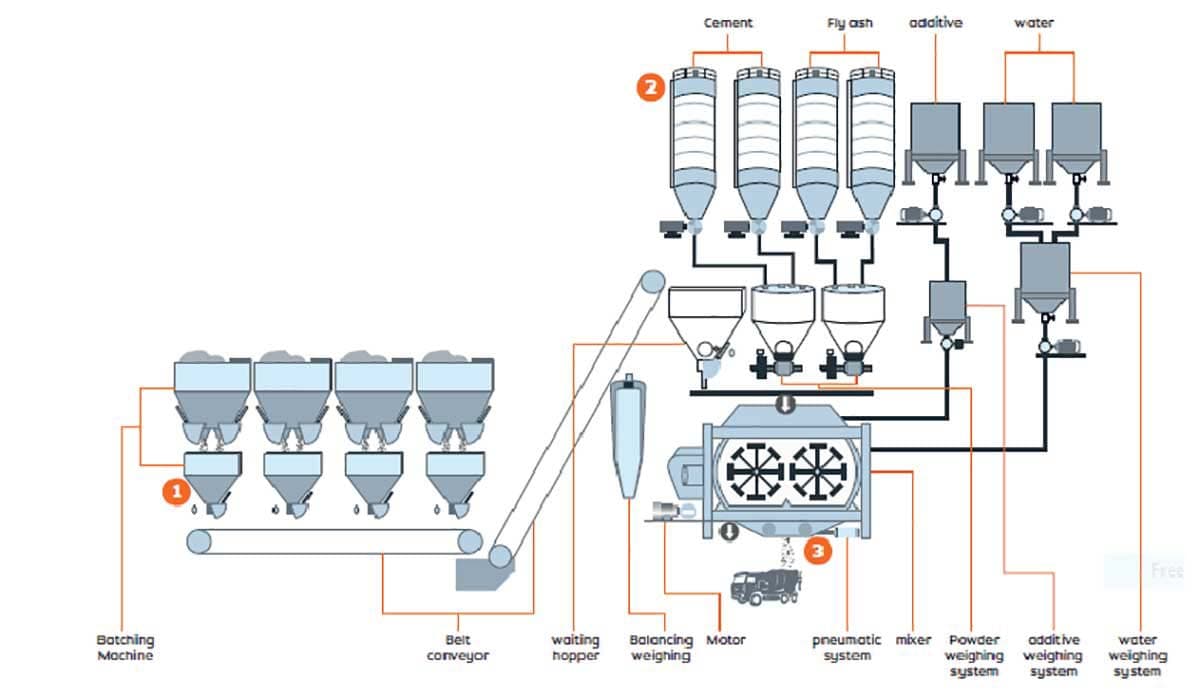

Stationary concrete mixing plant is a kind of equipment specialized in producing concrete. It consists of hopper, conveyor, mixer, metering system and control system, etc. The raw materials include cement, stone, sand, etc., which are mixed in a specific proportion under the control of the metering system and then enter the mixer for mixing to finally form concrete.

Stationary concrete mixing plant usually consists of the following parts.

The specification size of the mixing plant is named according to its theoretical production per hour. The commonly used specifications are: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240, etc. For example: HZS25 refers to the mixing plant with a production capacity of 25 cubic meters per hour, and the host is a double horizontal shaft forced mixer.

Stationary concrete mixing plants usually consist of huge twin-shaft mixers designed to provide full production capacity, efficiency and reliability for a wide range of large-scale and high-quality concrete production.

This type of concrete production plant is designed to provide maximum rated production capacity, the ability to work for long periods of time, and great flexibility to be used for multiple projects, especially large-scale infrastructure and precast concrete projects. Twin-shaft mixers offer better mixing results and lower maintenance costs than other types of mixers.

How a stationary concrete mixing plant works?

During the production process, raw materials such as aggregates, cement and sand are first placed in the corresponding warehouses and then weighed automatically or manually by the metering mechanism according to the recipe and proportions. After that, the raw materials are transported to the mixer for mixing, which usually takes about 3-5 minutes. The mixed concrete is transported to the concrete mixer truck or the finished product silo through the conveying equipment and finally used in the factory.

Modern stationary concrete mixing plants are designed with a focus on maximum capacity, high flexibility, efficiency and reliability for the continuous production of a wide range of high quality concrete.ZOOMJO manufactures stationary concrete mixing plants with capacities of 25, 35, 50, 60, 75, 90, 120, 180 and 240 m3/h. We can customize our production to meet the needs and capacity requirements of our customers.

The stationary concrete mixing plant has several advantages as follows.

1. The stationary concrete mixing plant has high production efficiency and can be automated, which improves the production efficiency.

2. The production cost of stationary concrete mixing plant is low compared with other concrete production methods.

3. The production process of stationary concrete mixing plant is controlled by metering system and control system, which ensures the stability of concrete quality.

4. The stationary concrete mixing plant can reduce the emission of waste gas and waste water, which can achieve the purpose of environmental protection and energy saving.

Stationary Concrete Mixing Plant VS Mobile Concrete Mixing Plant.

1. Stationary concrete batching plants usually have higher production capacity than mobile concrete batching plants because they usually have larger production capacity and higher degree of automation.

2. Stationary concrete mixing plants usually have a more stable infrastructure, so they are more stable in the production process, less susceptible to external environment, and easier to maintain and repair.

3. Stationary concrete mixing plant is suitable for large projects, such as highways, bridges, tunnels, dams, etc.

4. Stationary concrete mixing plants usually have better emission control system, which can reduce the pollution to the environment.

Stationary concrete mixing plant needs regular maintenance to ensure the normal operation and productivity of the equipment.

1. Equipment cleaning: Regularly clean the equipment surface and interior to prevent impurities from contaminating raw materials and concrete.

2. Lubricating oil replacement: Replace the lubricant of the equipment regularly to ensure the lubrication effect of the equipment.

3. Parts inspection: regularly check the parts of the equipment, such as belts, tires, transmission system, etc., and replace them in time when problems are found.

4. Safety protection: strengthen the safety protection of the equipment to prevent personnel from misoperation and accidents.

Fixed concrete mixing plant needs to pay attention to environmental protection and safety issues in the production process and comply with relevant environmental protection and safety regulations and standards.

1. Exhaust gas treatment: Fixed concrete mixing plants need to install exhaust gas treatment equipment to reduce exhaust gas emissions.

2. Waste water treatment: Fixed concrete mixing plants need to install waste water treatment equipment to reduce waste water discharge.

3. Personnel training: To strengthen personnel safety training and improve employees' safety awareness and emergency handling ability.

What are the factors to be considered in selecting the location of concrete mixing plant?

1. The site location should be as close as possible to the local power and water resources.

2. The installation location should be chosen with sufficient area to meet current and future needs, and consider issues such as pollution. The selected site should be far from residential areas.

3. When selecting a site for the installation of a stationary concrete mixing plant, flat land can reduce the cost of grading the site. The best natural conditions should be used to reduce costs.

4. Consideration should be given to the availability of good traffic facilities such as width of roads, height restrictions and capacity to avoid traffic jams. This is essential for smooth delivery of the produced concrete to the construction site.

5. The location of the site should be close to the point of sale where the concrete is produced. It is best to be close to quarries and sand plants, with a service radius of between 50 and 100 km, as transportation costs directly affect the price and profitability of the company.

ZOOMJO is a company specializing in the design, manufacture and sales of concrete mixing plants, the best manufacturer of stationary concrete mixing plants in China. The company covers an area of about 50,000 square meters and employs nearly 1,800 people, including engineers, professional technicians, managers, mechanics, sales team, after-sales service team and other service personnel. Our concrete mixing plants are popular and trusted by customers in Malaysia, Philippines, Indonesia, Pakistan, Uzbekistan, Australia, Fiji, Kenya, Nigeria, USA, Canada, Jamaica and France.

HZS / ZJ75 Stationary Concrete Batching Plant Configuration

| Model | HZS / ZJ25 | HZS / ZJ35 | HZS / ZJ50 | HZS / ZJ60 | HZS / ZJ75 | HZS / ZJ90 | HZS / ZJ120 | HZS / ZJ180 | HZS / ZJ240 |

| Productivity | 25m³/h | 35m³/h | 50m³/h | 60m³/h | 75m³/h | 90m³/h | 120m³/h | 180m³/h | 240m³/h |

| Concrete mixer | JS 500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | JS2000 | JS3000 | JS4000 |

| Mixer discharging capacity | 0.5m³ | 0.75m³ | 1m³ | 1m³ | 1.5m³ | 1.5m³ | 2m³ | 3m³ | 4m³ |

| Feeding Mode | Lift Hopper | Lift Hopper | Lift Hopper | Belt Conveyor | Lift Hopper | Belt Conveyor | Belt Conveyor | Belt Conveyor | Belt Conveyor |

| Aggregate batching machine | PLD800 | PLD1000 | PLD1600 | PLD1600 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Kinds of aggregate | 2/3/4 | 2/3/4 | 3/4 | 3/4/5 | 3/4 | 3/4/5 | 3/4/5 | 3/4/5 | 3/4/5 |

| Max aggregate size | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm |

| Discharging height | 3.8m | 4.1m | 4.1m | 4.1m | 4.1m | 4.1m | 4.3m | 4.3m | 4.3m |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement weighting accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| weight | 10t | 13.5t | 18.5t | 28t | 25t | 40t | 65t | 88t | 98t |

| General installed power | ≈65kw | ≈75kw | ≈100kw | ≈110kw | ≈140kw | ≈160kw | ≈220kw | ≈290kw | ≈340kw |

HZS / ZJ75 Stationary Concrete Batching Plant Related Product

-

HZS / ZJ120 Stationary Concrete Batching PlantHZS concrete batching plant is also called concrete mixing plant, concrete mixing station. It includes horiz…

HZS / ZJ120 Stationary Concrete Batching PlantHZS concrete batching plant is also called concrete mixing plant, concrete mixing station. It includes horiz… -

ZJM60 Foundation Free Concrete Batching PlantThe hopper-type foundationless concrete mixing plant is perfect for concrete construction due to its excelle…

ZJM60 Foundation Free Concrete Batching PlantThe hopper-type foundationless concrete mixing plant is perfect for concrete construction due to its excelle… -

ZJY-90 Mobile Concrete Batching PlantConcrete mixing plants can be portable, stationary or semi-portable. They are commonly used in applications …

ZJY-90 Mobile Concrete Batching PlantConcrete mixing plants can be portable, stationary or semi-portable. They are commonly used in applications …

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська