How Concrete Mixing Plants Works?

A concrete mixing plant is an assembly plant used to produce fresh concrete on a large scale. How does a concrete mixing plant work? It consists of several component parts and control systems that transform raw materials into high quality concrete through a precise batching, mixing and blending process.

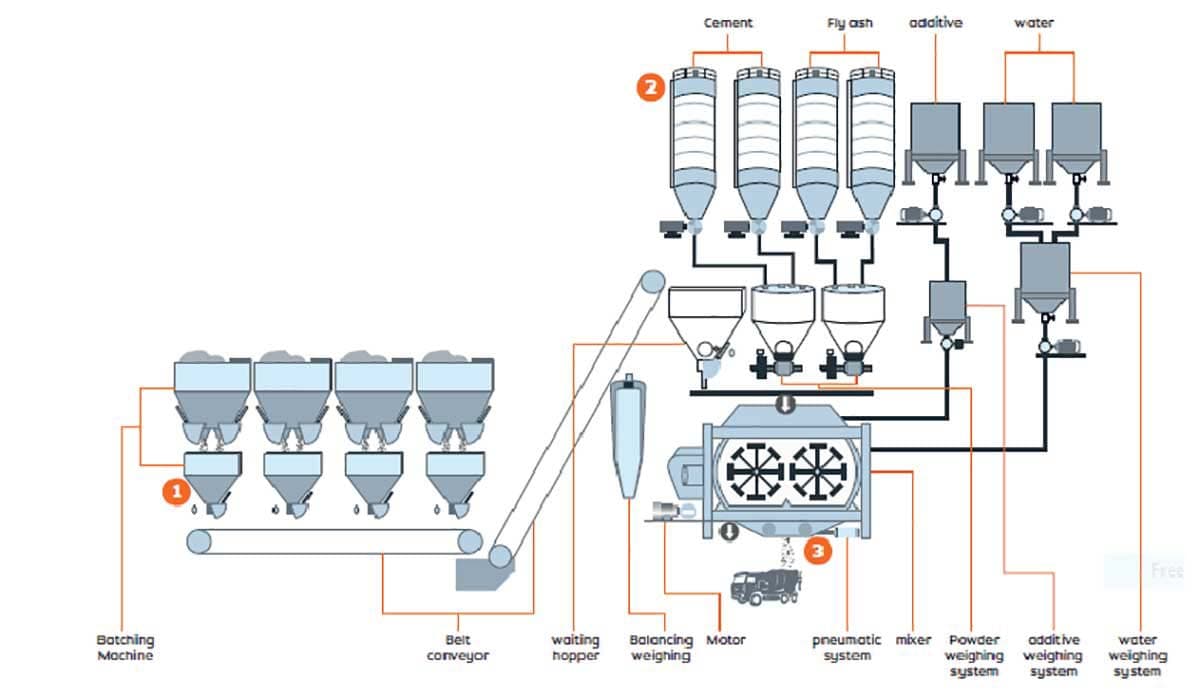

The workflow of a concrete mixing plant is as follows:

Aggregate is fed into the silo by wheel loader or belt conveyor. During the batching process, the material door is opened by a cylinder and the different aggregates enter their respective weighing hoppers for accurate weighing. The microcomputer will automatically make an overweight alarm to ensure the accuracy of the dosage. After finishing the dosage of the aggregates, they are conveyed by the flat belt conveyor to the inclined feeding belt conveyor.

Next, the material is transferred from the inclined belt conveyor to a transition hopper on top of the main mixer for temporary storage. This transition hopper serves as a temporary storage for the aggregates, thus shortening the cycle time of the mixing plant.

At the same time, the dust removal device collects the generated aggregates, cement and coal ash to prevent pollution. The energy storage bin includes components such as the bin, dust collector, level indicator, feed pipe, manual butterfly valve and arch breaking device.

The cement powder is conveyed via screw conveyor to the weighing hopper for metering. Precision load cells ensure accurate metering of the powder. Water and admixtures are piped to their respective weighing hoppers for weighing. After weighing, the butterfly valve below the admixture weighing hopper opens, discharging the admixture into the water weighing hopper for mixing and dilution, and then discharging through the mixer into the main mixer.

In the main mixer, all the materials are mixed by two axes, and by gravity they rise and then fall to achieve uniform mixing in both axes. Within about 60 to 72 seconds, the completed concrete mix material is unloaded, indicating that this batch of concrete mixing process is complete.

The process of working in a concrete mixing plant requires precise batching, mixing and blending steps to ensure the production of high quality concrete. It is very important for the operators to have knowledge about concrete batching, because only in this way they will be able to fully control and monitor the entire process and thus improve the quality of the concrete.

About the ZOOMJO concrete batching plant advantages in brief

In addition to the workflow, the ZOOMJO concrete mixing plant has a number of features and key components. For example, the ZOOMJO belt conveyor has a semi-enclosed design, which is waterproof and dustproof. The inclined belt conveyor is designed with maintenance walkways on both sides for easy access to the belt and is equipped with an emergency stop pull switch to ensure easy and safe access. At the same time, the inclined belt machine is equipped with a tensioning device to ensure sufficient tensioning force to prevent the belt from slipping. For cleaning, the top of the inclined belt machine is also equipped with automatic cleaning device, scraper and belt cleaning device to ensure that the belt is kept clean.

Another key component is the JS series double horizontal shaft forced mixer, which is a product developed by ZOOMJO Group. This mixer features high mixing efficiency, good uniformity, good sealing performance and safety and reliability. The mixer is composed of mixing system, feeding system, discharging system, water supply system and electrical system. The mixing barrel is welded together and five kinds of liners are used, which are tightly connected with the barrel to ensure the interchangeability of the liners. The main shaft seal adopts ZOOMJO patented sealing technology with multiple seals and uses imported original seals to ensure the reliability of the seal. The mixing blade adopts the new generation of double spiral continuous mixing design, replacing the traditional shovel type mixing blade, which can shorten the mixing time and improve the mixing uniformity.

In terms of lubrication system, the spraying device is designed directly above and parallel to the two main shafts to ensure a more even mixing process of water spraying in the main machine. The high-pressure water jet of pressure pump can quickly clean the residues attached to the two spindles and keep the spindles clean.

The control system is the key part of the concrete mixing plant, which issues the final command to inject the mixed materials into the concrete mixer through the discharge hopper for on-site construction.

As a professional manufacturer of concrete mixing plant equipment, ZOOMJO offers various types of concrete mixing plant equipment, including mobile mixing plant, stationary mixing plant, portable mixing plant, cement mixing plant and precast concrete mixing plant.

ZOOMJO concrete mixing plants are efficient and reliable machines designed for the mass production of high-quality fresh concrete. As a leading manufacturer, ZOOMJO is committed to providing advanced technology and innovative solutions to meet the needs of the construction industry for concrete production equipment.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська