ZBT60D Electric Concrete Trailer Pumps Product Description

Electric concrete trailer pump is a kind of dragging concrete pump, a new type of concrete conveying equipment, which is used for conveying and pouring work in concrete construction. It adopts electric power, which can transport concrete to the designated construction site and put concrete evenly to the construction site, thus improving the construction efficiency.

Usage Scenarios

ZBT series Trailer concrete pumps can transport concrete with aggregate size of 4cm and below, with a displacement range from 24m³/h to 100m³/h.The electric concrete trailer pump has a wide range of use scenarios, not only for construction sites, but also for concrete placement in bridge projects, highway construction, tunnels, water conservancy projects and other large projects. It has the advantages of high flexibility, convenient operation, good mixing effect, safety and reliability, simple maintenance, etc.

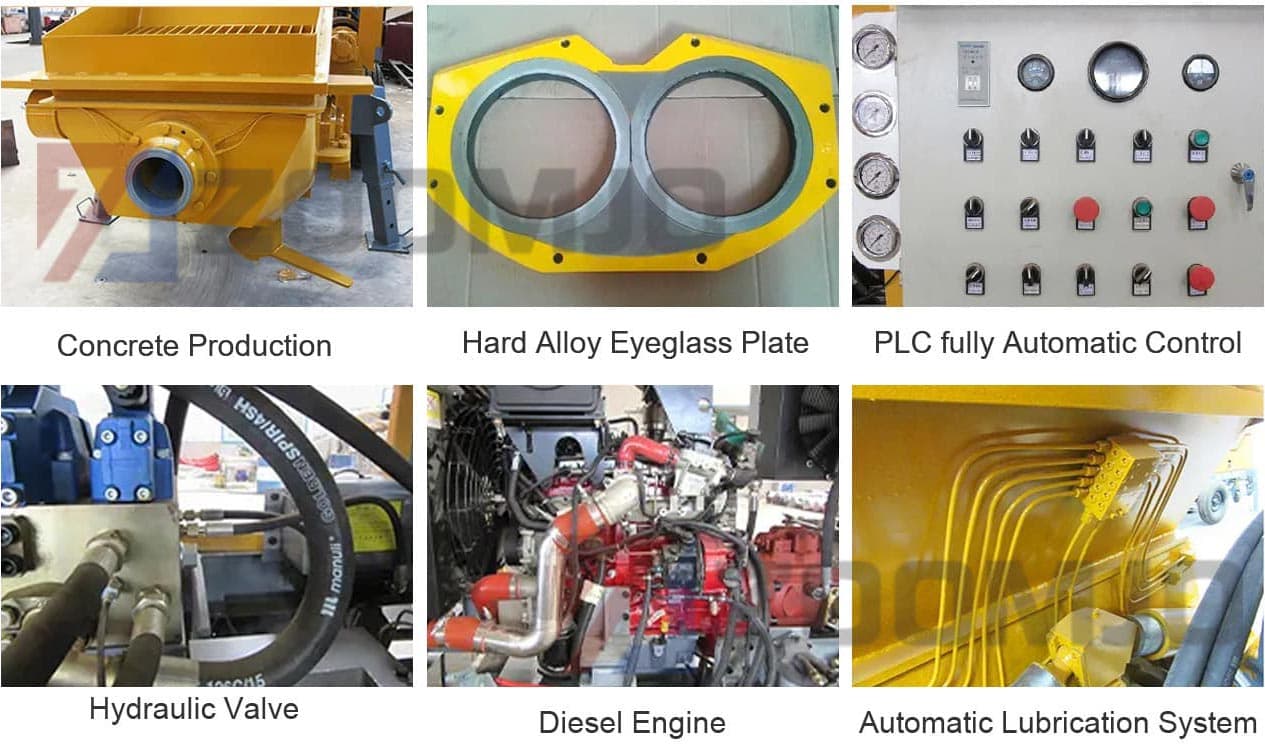

Product Structure

The structure of electric concrete trailer pump is composed of main unit, hydraulic system, control system, bracket, mixing system etc. It has the features of compact structure, convenient operation, good concrete placing effect, long concrete placing distance, safety and reliability, etc.

The electric concrete trailer pump produced by ZOOMJO has these advantages.

Power unit

There are multiple power units to choose from. The power unit of concrete pump is usually electric driven or diesel driven, depending on the model of the pump, different power motors or diesel engines are used.

Electrical system

The electric control system of electric concrete pump adopts OMRON programmable PLC, the line is simplified, the control is stable and reliable, the whole series is equipped with wireless remote control as standard, the operation is flexible and convenient.

Hydraulic system.

Our hydraulic system adopts electric control system, the system is mature and simple, low failure rate, the oil pump and valve group use famous brand products, mature technology, stable performance. This is the core system of the pump, the concrete pump can hit the concrete to dozens of floors of high buildings relying on the principle of hydraulic system.

Pumping system

Concrete pumping system, consisting of the main cylinder, delivery cylinder, piston and water tank, is the main component of the concrete pumping system.The parts use new materials and processes, and the service life of the conveying piston has increased significantly, and the service life of the spectacle plate and cutting ring has increased by more than 30% year-on-year.

Cooling system

It consists of air cooling and water cooling system, double cooling to ensure that the motor will not burn out, so that the concrete pump can realize long time continuous pumping.

Lubrication system that

Protect the transmission system of pumping machine and make it run more smoothly. The whole series adopts automatic centralized lubrication, high oil supply pressure, uniform oil supply, lubrication effect is guaranteed.

Structure material

The machine cover is made of thickened steel plate, which is wear-resistant and can better protect the core parts of the pump machine. The frame adopts thickened stainless steel square tube welding, stable and firm. The chassis of the concrete pump adopts trailer axle design, which is easy to move and convenient to transfer. The hopper adopts wider and wider setting, and the 30 degree inclined design is more convenient for loading.

Should I choose electric or diesel concrete trailer pump?

Mainly based on the construction area power factors to consider, if the external power is sufficient and convenient, you can choose the electric version of the concrete trailer pump, the cost of electricity is lower than diesel. Diesel concrete trailer pumps can be used in any construction site especially where there is no electricity, or where the power supply is unstable, such as river areas, tunnels, remote mountainous areas, etc.

Features of ZOOMJO's electric concrete trailer pump.

1. High pumping efficiency, the actual pumping efficiency reaches more than 80% of the theoretical value

2. Cost saving, it is much cheaper than concrete boom truck.

2. simple operation, the operator only needs to master certain operation skills to complete the operation of the trailer pump

3. easy maintenance, the electric towing pump does not need regular fuel replacement, only regular inspection.

4, good environmental protection, the electric towing pump does not produce harmful gases, in line with environmental requirements.

5, easy to move; the machine has wheels, we can use the car to tow it to another workplace.

The electric concrete trailer pump can achieve high efficiency when mixing concrete, which makes the concrete quality better. Our electric concrete trailer pump has been sold to Southeast Asia, Africa, South America and many other regions and countries, such as Singapore, Malaysia, Vietnam, Thailand, Indonesia, etc. The feedback from customers are very good, not only saving cost, but also improving construction efficiency, and getting good reputation of our products.

As a professional concrete pump supplier, ZOOMJO is committed to providing fixed concrete mixing plant, mobile concrete mixing plant, foundationless concrete mixing plant, concrete mixing pump, concrete trailer pump, self-discharging concrete mixer, etc. If you have any questions about concrete mixing equipment, you can communicate with us at any time, welcome your consultation.

ZBT60D Electric Concrete Trailer Pumps Configuration

| Model | ZBT40C-12-66 | ZBT60C-12--82 | ZBT80C-12.5--129 |

| Max. concrete output (m3/h) | 53/29 | 61/38 | 98/59 |

| Max.concrete pumping pressure (MPa) | 12/6 | 12/7 | 12.5/7.5 |

| Distribution valve type | S | S | S |

| Concrete cylinder diameter*stroke(mm) | 180/1300 | 200/1650 | 200/1800 |

| Hopper volume (m3) | 0.6 | 0.7 | 0.8 |

| Outlet diameter(mm) | 125 | 180 | 180 |

| Electrical engineering power(KW) | 66 | 82 | 129 |

| Rotate speed(r/min) | 2200 | 2200 | 2200 |

| Pumping system pressure(MPa) | 32 | 32 | 32 |

| Mixing system pressure(MPa) | 10 | 10 | 10 |

| Max mixing speed(r/min) | 25 | 25 | 25 |

| Capacity of oil tank(L) | 90 | 90 | 150 |

| Maximum conveying distance(m) | 120/500 | 180/1000 | 260/1200 |

| Max. aggregate diameter(mm) | 40 | 40 | 50 |

| lnside diameter of delivering pipe(mm) | 125 | 150 | 180 |

| Dimensions:(L*W*H)(mm) | 4800x1750x1900 | 4800x1750x1900 | 6000x2000x2200 |

| Total weight(kg) | 3500 | 4200 | 5800 |

ZBT60D Electric Concrete Trailer Pumps Related Product

-

ZBT60C Diesel Concrete Trailer PumpsDiesel Concrete Trailer Pumps are hydraulically fed with a double cylinder reciprocating operation of vibra…

ZBT60C Diesel Concrete Trailer PumpsDiesel Concrete Trailer Pumps are hydraulically fed with a double cylinder reciprocating operation of vibra… -

ZBT80C Diesel Concrete Trailer PumpsTrailer-mounted concrete pump is an efficient and flexible concrete conveying equipment, capable of conveyin…

ZBT80C Diesel Concrete Trailer PumpsTrailer-mounted concrete pump is an efficient and flexible concrete conveying equipment, capable of conveyin… -

ZBT80D Electric Concrete Trailer PumpsElectric trailer concrete pump has the characteristics of small volume, light weight, low motor power, easy …

ZBT80D Electric Concrete Trailer PumpsElectric trailer concrete pump has the characteristics of small volume, light weight, low motor power, easy …

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська