What Is The Concrete Pump?

Concrete pump is a kind of machinery used for conveying concrete in construction projects. It mainly consists of a pump body and a conveying pipe, which uses pressure to transport concrete continuously along the pipe. In large construction projects, concrete pumps are usually used in high-rise buildings, highways, overpasses and other occasions where a large amount of concrete is needed. Concrete pumps can be divided into piston type, extrusion type and hydraulic diaphragm type according to the structure form, among which piston type concrete pump is the main trend in the current construction field.

Structural features of concrete pump

Piston type concrete pump includes two types of hydraulic drive type and mechanical drive type. Hydraulic type concrete pumps are frequently used, while mechanical type concrete pumps are rarely seen in construction projects. Hydraulic drive concrete pump consists of hopper, hydraulic cylinder and piston, concrete cylinder, distribution valve, Y-pipe, flushing equipment, hydraulic system and power system. The hydraulic system pushes the piston back and forth under pressure. When the piston moves backward, it sucks in the material and when it pushes forward, it presses the concrete in the concrete cylinder through the Y-pipe into the delivery pipe. After finishing pumping concrete, the pump body and delivery tube can be cleaned using high-pressure water or compressed air.

The concrete pump has a series of structural features. The electric control system uses a fully enclosed electrical control box to protect the control device so that the concrete pump can work under harsh conditions. PLC programmable and simplified electrical apparatus is adopted to improve reliability and service life significantly, and it has fault display function for easy troubleshooting. The openable machine door of hydraulic system makes the operation and maintenance of the whole system more convenient. The machine door is made by special technology, which can reduce the operation noise. The open hydraulic system with double pumps and double circuits has a long service life and high reliability.

The pumping oil circuit adopts non-contact automatic reversing device and delay control device to avoid reversing shock and make the reversing accurate, stable and reliable. The hydraulic system is equipped with overflow protection and overpressure automatic cut-off and shut-off device, so that the main pump gets reliable multi-level protection. It also adopts oil suction and filtration technology to avoid foreign substances from entering the hydraulic circuit, which plays a great role in improving the reliability and service life of the system.

In addition, the conveying pipeline of the concrete pump is made of high-strength alloy steel with good wear resistance, which can ensure that no leakage and wear problems will occur during long time use. The conveying pipeline also adopts special process treatment, which makes its surface smooth, with low flow resistance and high pumping efficiency.

The compact structure and light weight of the pump body of the condensate pump make it easy to transport and move. At the same time, the pump has excellent performance and efficient pumping capacity, which can meet the needs of various different engineering occasions. Due to its structural features and excellent performance, the concrete pump has been widely used in modern construction and engineering fields, and has achieved remarkable results and achievements.

Advantages of concrete pump:

1. Save time and manpower. Traditional concrete conveying methods require a lot of manpower and longer time, while concrete pumps can quickly convey concrete to the required location, reducing the working period and improving the efficiency.

2. Easy to operate. Concrete pump is easy to operate, only a small number of workers are needed to complete the whole process, reducing the labor intensity of workers.

3. High efficiency of pumping concrete. Concrete pump can transport concrete to a long distance or high place, which can avoid the loss and accumulation caused by gravity, thus improving the construction quality.

4. Wide range of use. Concrete pumps can be used in various sizes and types of construction projects, such as high-rise buildings, bridges, tunnels, etc.

Operation of concrete pump

1. To ensure the safe operation and long service life of concrete pumps, the following are some operational specifications and recommendations:

2. Ensure that the particle size, cement grade and mix ratio of sand and gravel materials meet the requirements of the factory manual to meet the mechanical performance requirements of the pump.

3. Before operating the pumping equipment, use both parking brake and locking brake, wedge the tires, water supply is normal, water tank should be filled with fresh water, there should be no debris in the hopper, and all lubrication points should be lubricated normally.

4. Check whether the bolts of each part of the pumping equipment are tight, whether the pipe joints are tight and sealed, and whether the protection devices are complete and reliable.

5. Before operating each part, adjust the handle, hand wheel, control lever and valve body so that they are in the correct position. Check whether the hydraulic system is normal and leak-free.

6. Prepare cleaning pipes, cleaning supplies and other related devices. Before operation, lubricate the pipeline with prepared cement mortar as required. And let the unrelated personnel leave the pipeline.

7. Before starting the discharge boom, the landing leg should be fully extended and firmly supported. The boom can be rotated only after the support is lifted.

8. The boom should be extended sequentially when it is placed. Lifting or dragging objects with the boom is strictly prohibited. It is forbidden to move the car body when the boom is in the fully extended state. When it is necessary to move the car body, the upper placement boom should be folded and fixed, and the moving speed should not exceed 10km/h.

9. When placing the boom, it is not allowed to use the pipe line whose diameter exceeds the specified standard. In addition, the installed wheel pipe should be tied with fall protection rope belt.

10. Monitor various instruments and indicators at any time, and adjust or deal with abnormalities in time. For example, when the conveying pipe is blocked, reverse operation should be performed to send the concrete back to the hopper. If necessary, the pipe should be removed to eliminate the blockage.

11. When the pumping system is under pressure, it is forbidden to open any conveying pipes and hydraulic pipes.

12. After the operation, all concrete in the hopper and piping should be output, and then clean the pump, hopper and piping.

During the operation, the following matters should also be noted:

1. do not overload the concrete pump and operate it in accordance with the maximum flow rate, maximum pressure and maximum particle size specified in the manual;

2. perform regular maintenance on the concrete pump, including replacing wearing parts, cleaning the hydraulic system, checking the electrical system, etc;

3. should pay attention to safety when operating, wear the necessary protective equipment, and strictly prohibit to put hands or other objects into the concrete pump or pipeline

4. during operation, indicators such as pressure and temperature of the hydraulic system should be monitored at all times and any abnormalities found should be dealt with in a timely manner;

5. the operator should receive professional training, understand the structure and working principle of the concrete pump, and be familiar with the name, role and operation method of each part

6. before operation, inspection and test run should be carried out to ensure that the equipment runs normally, all parts are linked and coordinated, and the hydraulic system has no leakage and other problems.

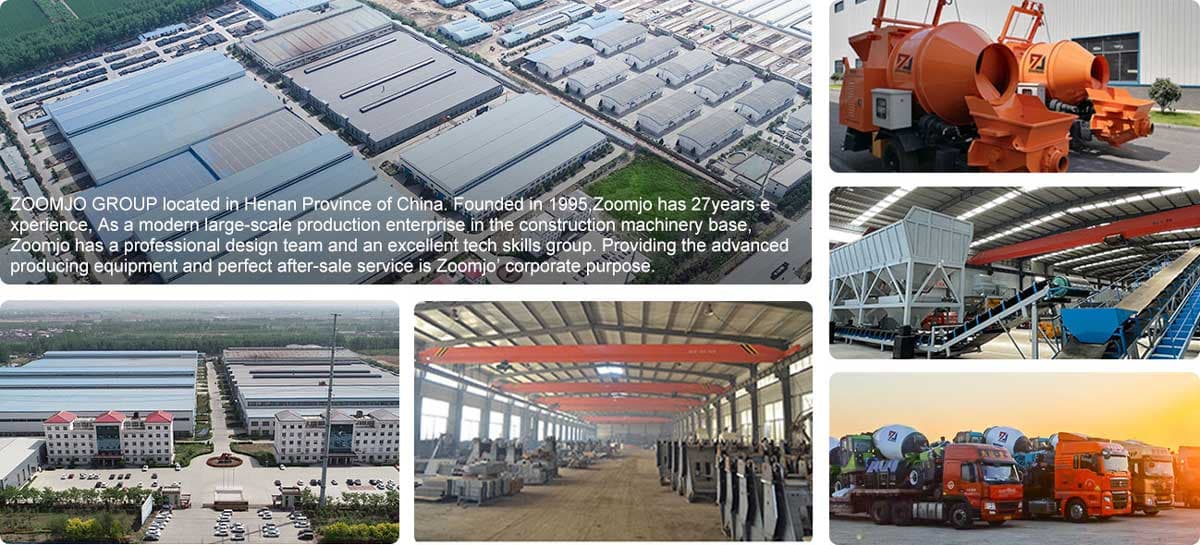

ZOOMJO offers small concrete pumps, diesel concrete pumps, electric concrete pumps, concrete trailer pumps and concrete mixers. If you have any questions about concrete pump price, please feel free to contact us.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська