Reliable Stationary Concrete Batching Plant for Sale

Concrete is an essential material in modern construction and infrastructure development. In order to meet the concrete needs of different projects, manufacturers are constantly pushing the boundaries by offering various types of concrete mixing plants. Among them, ZOOMJO Group's stationary concrete mixing plants are popular in the market and have become the first choice for projects such as high-rise buildings, bridges, tunnels and harbors.

A stationary concrete plant usually consists of several important components that work together to ensure the production of high-quality concrete. Unlike mobile concrete batching plants, stationary concrete batching plants stand out for their stability and efficiency. It is a complete concrete production facility that mixes cement, sand, water and other admixtures to produce concrete in various proportions.

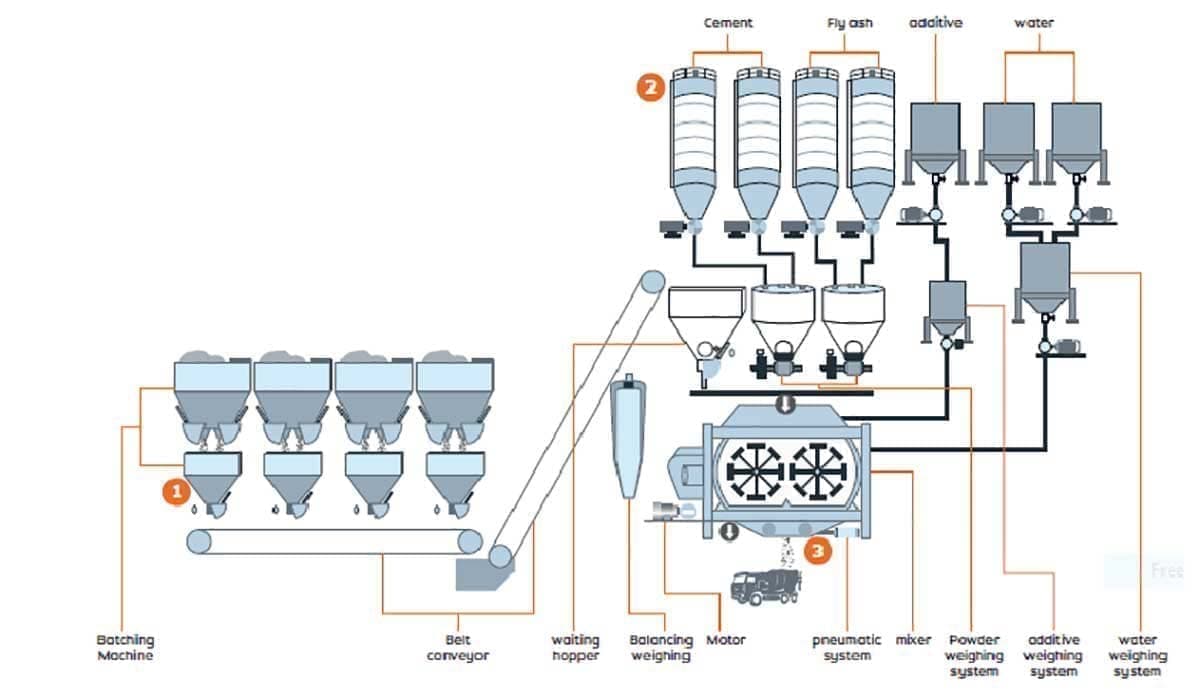

Main Components of Stationary Concrete Batching Plant

A stationary concrete mixing plant usually consists of the following major components:

Aggregate supply system: this consists of aggregate silos or concrete batchers for storing different raw materials such as crushed stone and sand. The number of aggregate bins can be customized as per the project requirements. Each bin is equipped with load cells to ensure accurate batching.

Cement and Fly Ash Supply System: Cement and fly ash are important components of concrete, which are weighed and transported to the concrete mixing plant via screw conveyors.

Water and Admixture Supply System: The water and admixture supply system is used to add water and other chemicals to meet the concrete proportioning requirements.

Weighing System: Each raw material is weighed and its weighing information is accurately fed back to the control system.

Concrete Mixer: This is the core component of a stationary concrete mixing plant. The mixer adopts a twin-shaft paddle type design with high mixing efficiency and the ability to provide high quality concrete.

Control System: The control system is responsible for monitoring and coordinating the operation of each component to ensure the accuracy of concrete proportioning and production efficiency.

Workflow of Stationary Concrete Batching Plant

The workflow of stationary concrete mixing plant is as follows:

1. Aggregate (gravel, sand) is loaded into the storage bin of the concrete batching machine by the loader, then weighed and fed into the feed hopper of the concrete mixer.

2. at the same time, cement is conveyed from the cement silo to the cement weighing hopper via screw conveyor, and water and additives are conveyed from the liquid supply system to the water and additives weighing hopper.

3. After the materials are weighed, the control system activates the corresponding pneumatic valves to feed the aggregate, water, cement and additives into the concrete mixer for uniform mixing.

4. The evenly mixed concrete mixture is finally transported to the concrete mixer truck through the discharge gate, ready for transportation to the construction site.

Common Types of Stationary Concrete Batching Plant

There are two main types of Stationary Concrete Batching Plants in terms of aggregate conveying methods, namely skip-type Stationary Concrete Batching Plants and belt-conveyor Stationary Concrete Batching Plants. These two types have their own unique applications and advantages in concrete production.

Skip type stationary concrete mixing plant:

A skip type mixing plant usually uses a skip or bucket conveyor to supply the aggregate. The main feature of this design is that the aggregate accumulates in the skip and the placement of the aggregate is then controlled by the opening and closing of the skip. This process is very precise and allows control of the quantity of each aggregate to be placed. Skip conveyors are usually suitable for small or medium sized concrete mixing plants as they allow for high accuracy in the supply of aggregates in a limited space. This design is useful for projects that require more frequent and accurate aggregate proportioning.

Specifications of skip type stationary concrete batching plant:

| Model | HZS / ZJ25 | HZS / ZJ35 | HZS / ZJ50 | HZS / ZJ75 |

| Productivity | 25m³/h | 35m³/h | 50m³/h | 75m³/h |

| Concrete mixer | JS 500 | JS750 | JS1000 | JS1500 |

| Mixer discharging capacity | 0.5m³ | 0.75m³ | 1m³ | 1.5m³ |

| Feeding Mode | Lift Hopper | Lift Hopper | Lift Hopper | Lift Hopper |

| Aggregate batching machine | PLD800 | PLD1000 | PLD1600 | PLD2400 |

| Kinds of aggregate | 2/3/4 | 2/3/4 | 3/4 | 3/4 |

| Max aggregate size | 80/100mm | 80/100mm | 80/100mm | 80/100mm |

| Discharging height | 3.8m | 4.1m | 4.1m | 4.1m |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% |

| Cement weighting accuracy | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% |

| weight | 10t | 13.5t | 18.5t | 25t |

| General installed power | ≈65kw | ≈75kw | ≈100kw | ≈140kw |

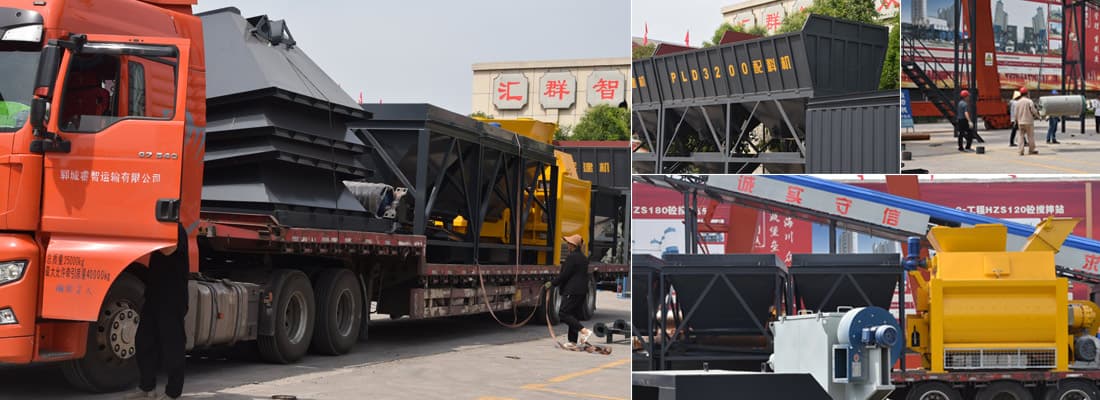

Belt Conveyor Type Stationary Concrete Batching Plant:

Unlike the skip type, the belt conveyor stationary concrete batching plant uses a belt conveyor to supply the aggregate. This design is usually suitable for larger concrete batching plants as they can handle larger quantities of aggregates. The belt conveyor transports the aggregate from the storage silo to the feed hopper of the concrete mixer via a conveyor belt. This is more suitable for larger projects where large quantities of concrete are required and the accuracy of the aggregate is not as important as in the skip type.

Belt Conveyor Fixed Concrete Batching Plant Specifications:

| Model | HZS / ZJ60 | HZS / ZJ90 | HZS / ZJ120 | HZS / ZJ180 | HZS / ZJ240 |

| Productivity | 60m³/h | 90m³/h | 120m³/h | 180m³/h | 240m³/h |

| Concrete mixer | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

| Mixer discharging capacity | 1m³ | 1.5m³ | 2m³ | 3m³ | 4m³ |

| Feeding Mode | Belt Conveyor | Belt Conveyor | Belt Conveyor | Belt Conveyor | Belt Conveyor |

| Aggregate batching machine | PLD1600 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Kinds of aggregate | 3/4/5 | 3/4/5 | 3/4/5 | 3/4/5 | 3/4/5 |

| Max aggregate size | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm |

| Discharging height | 4.1m | 4.1m | 4.3m | 4.3m | 4.3m |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement weighting accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| weight | 28t | 40t | 65t | 88t | 98t |

| General installed power | ≈110kw | ≈160kw | ≈220kw | ≈290kw | ≈340kw |

Features and Advantages of Stationary Concrete Batching Plant

The features and advantages of stationary concrete mixing plant make it the first choice for many projects:

1. Adopting twin-shaft concrete mixer can realize high mixing efficiency and high quality concrete at the same time. The twin-shaft paddle mixer is able to cut the mixing time in half while improving the uniformity of the concrete.

2. The use of wear-resistant parts extends the equipment's service life and reduces maintenance and replacement costs.

3. Stationary concrete mixing plant is designed with low energy consumption, which can save cost for investors.

4. Stable operation improves the reliability of the equipment and ensures that the concrete produced is accurately proportioned.

Successful Cases of Stationary Concrete Batching Plant

ZOOMJO Stationary Concrete Batching Plant in Garoacan, Philippines

Concrete Batching Plant for Concrete Pipe Production in Guinea

Ready Mix Concrete Batching Plant for Sale in Thailand

ZOOMJO Stationary Batching Plant Successfully Installed in Myanmar

ZOOMJO Successfully Installed 50m³/h Stationary Concrete Batching Plant in Myanmar

Hzs120 Concrete Batching Plant Exported to Ghana

Stationary concrete batching plants are a key tool in the modern construction industry, providing high-quality concrete for a wide range of projects.ZOOMJO Group's stationary concrete batching plants are the preferred choice in the construction industry due to their high efficiency, stability and reliability. If you are in need of a concrete mixing plant, consider partnering with ZOOMJO Group and we will provide you with the best possible solution for your concrete production with our extensive experience and technological advantages.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська