Trailer-Mounted Concrete Pump Truck Routine Maintenance & Cleaning Methods

Concrete transfer pump truck is a very important construction machinery, which is widely used in construction projects. However, how to maintain the concrete conveying pump truck is a problem that every construction unit needs to pay attention to.

Good daily maintenance is the key to the good operation of concrete transfer pump truck. For the daily maintenance of the pumping system, we should regularly discharge the water at the bottom of the tank and fill the tank with fresh water and lubricating grease to ensure that the concrete piston is well sealed and no mortar seeps into the tank.

We also need to check the spacing between the cutting ring and the glass plate and clean the whole system thoroughly to check the wear parts and make sure the spacing between the cutting ring and the glass plate is not more than 2mm. If it is more than 2 mm, that spacing needs to be adjusted. It is also necessary to check the piston and replace it with a new one if necessary, and check the wear of the S-pipe and axle of the concrete transfer pump truck, check the wear of the mixing unit, mixing blade and mixing shaft, check the air pressure of the energy reservoir, and check the connection and welding joints of the structural parts, as well as the engine oil level.

Daily maintenance of pumping system

Drain water from the bottom of the tank regularly (every 10 days or every 50 working hours).

Fill the water tank with fresh water and the lubricating oil tank and points with lubricating grease.

Make sure that the concrete piston is well sealed and that no mortar has seeped into the tank.

Check the spacing between the cutting ring and the glass plate (max. 2 mm).

Clean the whole system thoroughly and check the worn parts after each use.

If the spacing between the cutting ring and the glass plate is more than 2 mm, adjust this spacing.

Check the piston and replace it with a new one if necessary.

Check the wear of the S-tube and axle of the concrete transfer pump truck.

Check the wear of mixing unit, mixing blade and mixing shaft.

Check the air pressure of the energy reservoir (10-11MPa).

Check the connections and welding joints of structural parts.

Check the engine oil level. Replenish or replace the oil if necessary.

Check the wear of the concrete cylinder. If the chrome plating is severely worn, replace it with a new one.

For routine maintenance of truck chassis, we need to check engine oil level and oil quality, check cooling water level and temperature, check oil pressure of engine oil, check tire wear and pressure, check electrical system, check visibility range of mirrors, check air pressure of brake system, check oil and air leaks, tighten joints if there are oil or air leaks, and check all moving parts before starting the pump truck.

Routine maintenance of the truck chassis

Check engine oil level and oil quality.

Check cooling water level and temperature.

Check engine oil oil pressure.

Check tire wear and pressure.

Check the electrical system (e.g., lights, indicators, STOP lights, etc.).

Check the visibility range of the rearview mirror.

Check the air pressure of the brake system.

Check for oil and air leaks (if there are oil or air leaks, tighten the fittings).

Check all moving parts (fixed outriggers, etc.) before starting the pump truck.

Daily cleaning methods

We also need to pay attention to the cleaning of the remaining concrete in the concrete pump pipe. After each construction, the remaining concrete in the concrete pump pipe should be cleaned in time. Daily cleaning will greatly extend the service life of the concrete transfer pump truck. Before cleaning, it is recommended to pump 0.52-1m3 of mortar first. Stop after all pumping is finished. Flip the flat valve switch and then unload the pressure of the accumulator. There are two cleaning methods, water cleaning and air cleaning. No matter which way is used, the valve box and hopper should be thoroughly cleaned. Air cleaning has some danger, requires strict sealing of the pipe and the cleaning length cannot be too long, so water cleaning is widely recommended.

It should be noted that in the process of use, attention should be paid to prevent the pipeline from clogging. Once the duct is found to be clogged, it should be stopped and cleaned in time. If the pipe blockage is not serious, it can be cleaned by reverse pump cleaning method. If the blockage is more serious, you need to remove all the concrete from the pump body, clean it and then restart the concrete pump truck.

Daily maintenance is the key to keep the concrete transfer pump truck running well. Only by carrying out standardized and thorough daily maintenance and cleaning can we ensure that the concrete transfer pump truck will work stably and efficiently for a long time. At the same time, pay attention to operating skills and ensure safety are issues that must be paid attention to during the operation of the concrete transfer pump truck.

The following points are also our usual maintenance of concrete mixer pumps need to pay attention to:

1, regular replacement of filter elements and filters. The function of the filter element and screen is to prevent impurities and particles in the concrete transfer pump truck from entering the pumping system to ensure the normal operation of the system. Regular replacement of the filter element and screen can prevent them from clogging and damage, thus ensuring the long-term service life of the pump truck.

2、Keep the temperature of the pumping system. In cold weather, special attention should be paid to the temperature of the pumping system to prevent the concrete from freezing or solidifying during the conveying process, leading to blockage or damage of the pumping system.

3、Pay attention to the quality of concrete. In order to avoid blockage or other problems in the concrete pumping process, attention should be paid to the quality of the concrete, such as water-cement ratio, aggregate size, impurity content, etc. If the quality of concrete is not qualified, it needs to be adjusted or replaced in time.

When using the concrete transfer pump truck, you also need to pay attention to the operating skills. When operating, you should first turn on the concrete pump truck's water pump, and then start the engine. During use, attention should be paid to the working condition of the concrete pump truck, especially when pumping high-rise buildings, special attention should be paid to safety to avoid overturning or accidents.

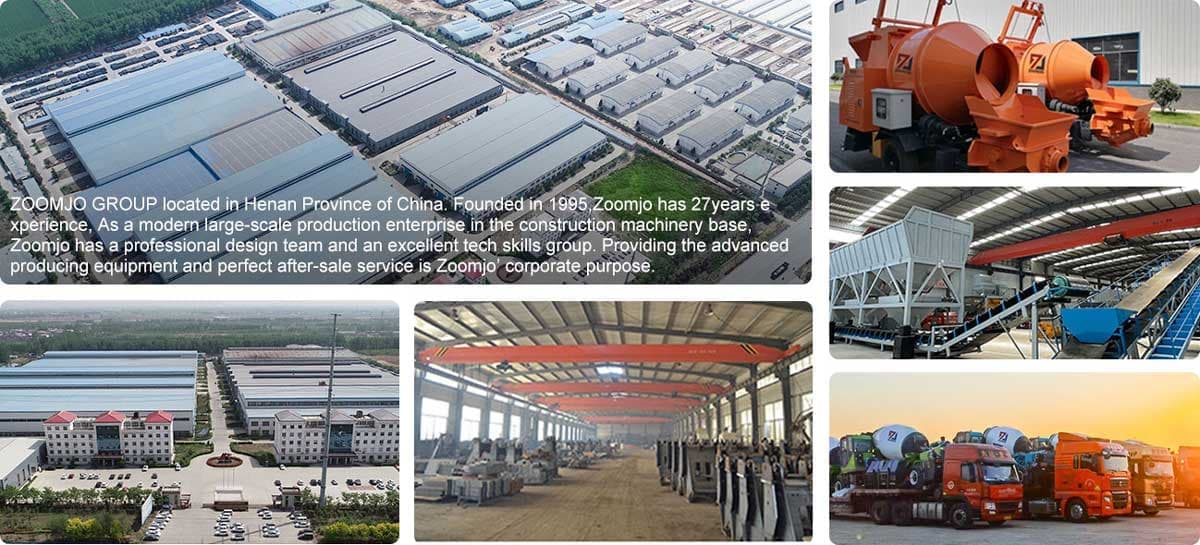

ZOOMJO is a professional concrete mixing equipment manufacturer, dedicated to providing high quality, efficient and reliable concrete equipment solutions to customers worldwide. With independent R&D and production capacity, the company always insists on technological innovation and quality management to ensure that its products are in the leading position in terms of performance and reliability. zOOMJO focuses on customer needs and provides personalized customization services and professional after-sales support to provide customers with a better quality experience and service guarantee.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська