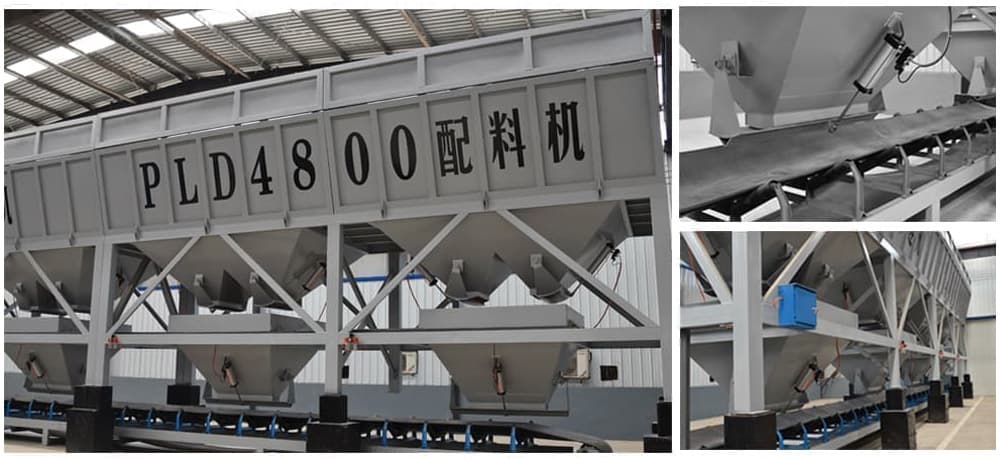

What is the Aggregate Batching Plant?

Accurate batching is key to ensuring the quality of the final product during the concrete production process. Aggregate batching machine, also known as automatic sand and gravel batching plant, is a key equipment used for quantitative distribution of aggregates in the concrete industry. It can replace manual bench scales and volumetric batching stations, realizing automation, efficiency and accuracy in the batching process.

Classification of Aggregate Batching Plant

Aggregate batching machine can be classified according to different criteria. Firstly, based on the type of aggregate, it can be categorized into two hopper, three hopper and four hopper plants. These classifications refer to the number of hoppers or storage bins used to mix different types of aggregates such as sand, gravel, and crushed stone. For example, a three-hopper batcher can store and control the distribution of three different aggregates.

Second, based on the method of measurement, aggregate batchers can be categorized into cumulative and individual measurement methods. The cumulative measurement method involves measuring all components (aggregate, cement, water, etc.) together before mixing, while the individual measurement method involves measuring each component separately before mixing. Obviously, the latter allows for more accurate batching.

Further, based on the mode of operation, aggregate batchers can be categorized into belt-type batching stations and cylinder-type batching plants. Belt-type batching stations use a conveyor belt to transfer aggregates from the hopper to the mixing unit and are suitable for large-scale operations, while cylinder-type batching plants use cylinders to control the discharge of aggregates into the mixing unit and are suitable for smaller-scale operations.

Components of an Aggregate Batching Machine

Aggregate batchers consist of three main components: the feeding system, the weighing system and the electrical control system. The feeding system is responsible for storing the aggregates and transporting them to the weighing hopper under the guidance of the control system; the weighing system is the key component of the batching plant, consisting of the hopper, the suspension system, the sensors and the batching controller; and the electrical control system is responsible for managing the weighing, the display, the operation and the automatic proportioning.

Working Principle of Aggregate Batching Plant

The working principle of aggregate batching plant is relatively simple. First, aggregates such as sand and stone are fed into each hopper by a loader. Then, the recipe is entered into the weighing controller as required. When the batching button is pressed, the batching machine will begin the automatic batching process. This process involves the systematic handling of the constituent materials such as sand and gravel, and is usually carried out in the following steps: loading of aggregates, recipe entry, initiation of the batching process, automatic batching and output processing.

ZOOMJO Aggregate Batching Machine Suppliers

ZOOMJO Aggregate Batchers are technologically advanced, with up to 6 bins and a maximum volume of 30 cubic meters in a single bin, easily meeting the material stockpiling needs of large concrete production projects. We can also customize aggregate batchers with special specifications according to your application scenarios and individual needs. For example, a 5-bin batching plant can accommodate a wider variety of aggregates, providing you with a wider choice of concrete formulations.

In addition to aggregate batchers, ZOOMJO also provides stationary, mobile and foundationless concrete mixing plants, as well as a full range of pre-sales, sales and after-sales services to meet your diversified needs.

If you have any needs or questions about aggregate batching plant, please feel free to contact us. Our experts will get back to you within 24 hours with professional support and solutions.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська