Small Concrete Batching Plants:Comprehensive Guide

Concrete mixing plants are indispensable equipment in the construction industry for the production of high quality concrete. While large stationary batching plants are usually used for large-scale projects, small concrete batching plants are ideal for small-scale construction projects thanks to their compactness, versatility and cost-effectiveness.

What is a Small Concrete Batching Plant?

Small concrete batching plants, also known as compact or portable batching plants, are designed for projects with moderate concrete needs. They are compact, easy to install, and cost-effective for a variety of applications, as listed below:

Small buildings: residential, commercial, light industrial, etc.

Foundations: foundations, slabs and other concrete foundations for all types of structures.

Paving Projects: sidewalks, driveways, parking lots and other paved surfaces.

Precast Concrete: production of precast concrete components such as beams, blocks and paving bricks.

Common Types of Mini Concrete Batching Plants

Small concrete batching plants are available in a variety of configurations to meet different project needs, common types include:

Compact Concrete Batching Plants

These mixing plants consist of small units of pre-engineered or pre-wired production equipment that are usually transported in batches to be assembled on site.

Mini Mobile Concrete Batching Plants

Mobile mixing plants consist of portable shaft mixers that are mounted on towable chassis with wheels for maximum mobility and quick installation.

Benefits of choosing a small concrete mixing plant

Cost-effective: Compared to large stationary batching plants, small batching plants typically have a lower initial investment cost, making them more suitable for smaller projects and contractors.

Space-saving: The compact design allows for installation in areas where space is limited, making it suitable for urban construction sites or projects with a restricted footprint.

Mobility: Portable and mobile models offer the flexibility to move between job sites, reducing transportation costs and increasing project efficiency.

Ease of Installation: Modular design and simplified components often facilitate fast, straightforward installation, minimizing downtime and getting projects started faster.

Efficient production: small concrete batching plants are small in size, but are able to produce concrete efficiently to meet the needs of all types of construction projects.

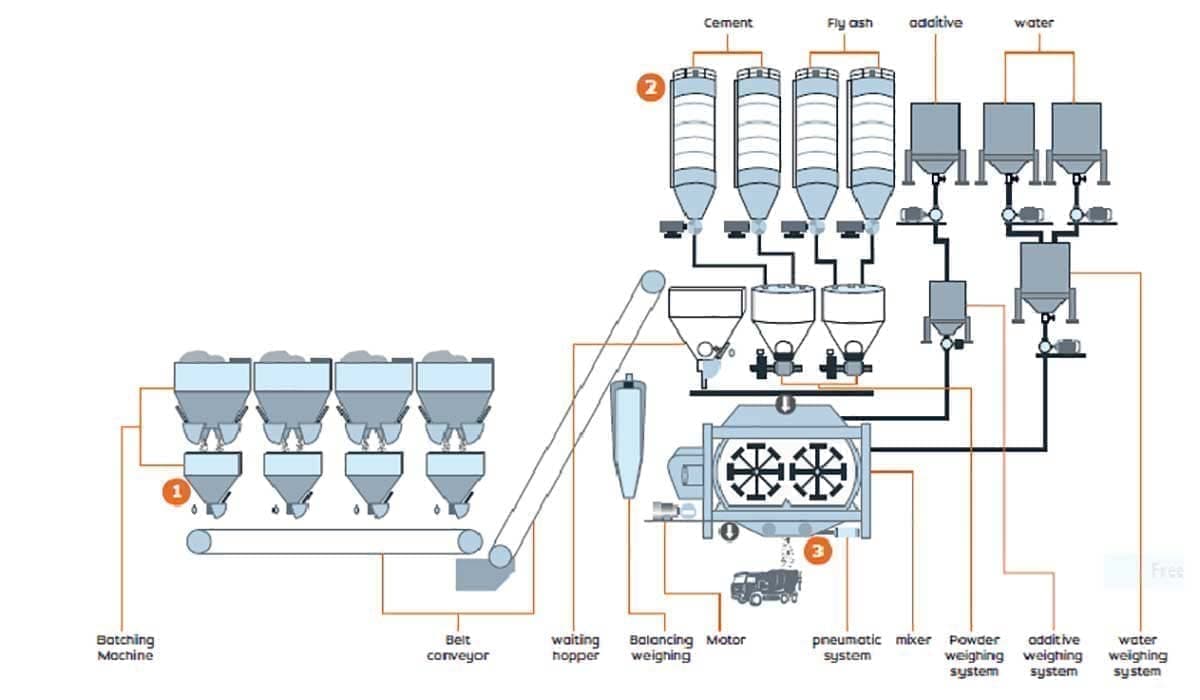

Components of a Small Concrete Batching Plant

A typical small concrete plant consists of the following key components that work together to produce high quality concrete:

Batching machine: accurately measures and distributes raw materials (cement, sand, gravel, water) according to the desired concrete mix design.

Twin shaft mixer: fully mixes the measured raw materials into a homogenous concrete mixture.

Cement silo: stores and supplies cement to the batching machine.

Screw conveyor: transports the cement from the silo to the batching machine.

Water supply system: controls and delivers the required amount of water to the batching process.

Control system: manages the entire production process, including sequencing, monitoring and adjustment.

Aggregate conveying system: transports sand and gravel from the storage silo to the batching machine.

Operator Platform: Provides a secure and accessible area for the operator to monitor and control plant operations.

How much does it cost to build a small concrete batching plant?

The price of a small concrete batching plant depends on its capacity, features and brand. Typically, the cost ranges from $3,000 to $200,000. Below is an approximate list of prices based on production capacity:

8 to 13 cubic meters/hour: US$3,000 to US$15,000

10 to 30 m3/hour: US$10,000 to US$30,000

20 to 60 m3/hour: $30,000 to $100,000

30 to 200 m3/hour: $100,000 to $200,000

Small Concrete Batching Plant Manufacturer Recommendation

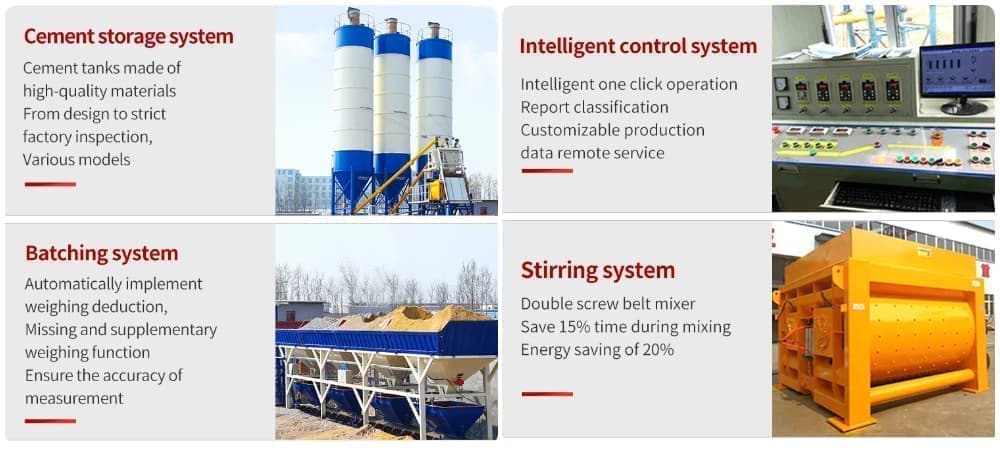

ZOOMJO is a company that specializes in manufacturing a wide range of construction equipment, including small concrete mixing plants. These mixing plants are designed for projects that require the right amount of concrete, such as small construction, foundation and paving projects.

Here are some of the features and benefits of ZOOMJO's small concrete mixing plants:

Compact design: compact design, easy to transport and suitable for sites with limited space.

Easy to install: Easy to install and operate, saving time and cost in construction projects.

Economical and efficient: more economical and efficient than large stationary mixing plants.

Durable construction: built with durable materials to meet the needs of the construction site.

Other Considerations for Choosing a Small Concrete Batching Plant

When choosing a small concrete mixing plant, the following factors should also be considered:

Production capacity: the amount of concrete that can be produced per hour.

Mixing time: the time required to mix a batch of concrete.

Aggregate storage capacity: the amount of aggregate that can be stored in the mixing plant.

Water storage capacity: the amount of water that can be stored in the mixing plant.

Admixture Dispensing System: Allows the addition of admixtures to improve concrete properties such as strength, workability or setting time.

Small concrete batching plants are an integral part of a construction project, especially when land is limited or budget is restricted. Choosing the right mixing plant, taking into account its production capacity, mixing time, storage capacity and admixture distribution system, will help the project run smoothly.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська