Manufacturer Of Skip Type Concrete Mixing Plant For Sale

What is a skip type concrete mixing plant?

A skip type concrete mixing plant is a type of stationary concrete mixing plant that is widely sold and used. It is popular for its compact design and high efficiency.

A skip type concrete mixing plant works by feeding aggregate and sand into an electric cement mixer through a skip hopper, hence the name skip type concrete mixing plant. Among the brands available in some European countries, only this type of ready-mixed concrete mixing plant is offered, regardless of the size of the project.

ZOOMJO's skip type concrete mixing plants are mainly intended for customers who need ready-mixed concrete and not for selling concrete to end users.

The skip type concrete mixing plant has the following characteristics:

1. compact design and high efficiency: modular structure design, small footprint, flexible placement according to the actual situation on site, concrete can be unloaded from several directions. The optimized design of each component makes it have the same efficiency as belt-conveyed concrete mixing plant.

2. Smooth operation of lifting mechanism and low failure rate: dynamic drop point feeding is adopted for smooth lifting; rope loosening protection limit to avoid reverse rotation.

3. Precise weighing system: the cement weighing hopper adopts octagonal design, good rigidity and smooth discharge; independent free weighing frame and pneumatic self-balancing technology prevent the phenomenon of supporting and pulling the scale.

4. Integrated layout, quick installation: the main components of the whole concrete mixing plant are integrated with the water and air lines, most of the components are installed in the factory with pre-determined interfaces, and the installation can be completed within three days after arriving at the construction site.

5. Reliable and durable wearing parts: Adopting tempered H-type steel rails, the rails are not easily deformed, and the skip elevator hopper is protected by intelligent devices such as sensors and travel switches during operation, which is safe and reliable. The service life of wearing parts is extended to more than 50,000 cubic meters, and the bucket never falls.

6. easy maintenance and operation: multiple intelligent designs, automatic lubrication, automatic alarm, reliable electrical components are used to reduce the difficulty of maintenance; with automatic dosing, automatic control and data recording functions, easy to operate.

7. Environmental protection and energy saving: skip type concrete mixing plant adopts closed design to reduce the emission of dust and noise. Meanwhile, the electric cement mixer and other components have high energy utilization efficiency to reduce energy consumption.

The skip type concrete mixing plant is a common type of concrete production equipment, and its layout and working principle are crucial to understand and operate this equipment. In the following, we will introduce the layout and working structure of skip type concrete mixing plant.

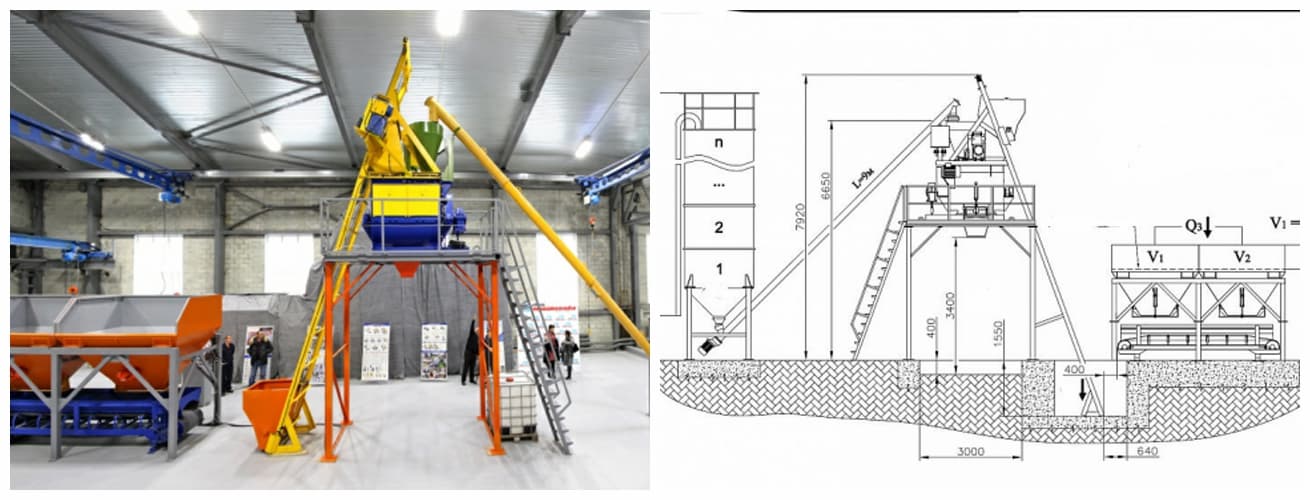

First, let's take a look at the working structure of a skip type concrete mixing plant. This diagram shows the various components of the concrete mixing plant so that we can clearly understand its work flow.

How does a concrete mixing plant work?

The working process of a concrete mixing plant starts with the wheel loader providing different sizes of aggregates and sand to the storage hopper. These aggregates and sand will be weighed by load cells to ensure the accuracy of concrete proportioning. After weighing, the aggregate and sand will be conveyed to the skip type elevating feed hopper of the horizontal shaft mixer. The elevating hopper lifts the aggregate and sand to the concrete mixer's inlet.

During the mixing process, cement is supplied from a metal silo by a screw conveyor and water is supplied by a pump. The water and cement are also weighed by load cells to ensure the accuracy of the material proportions during the mixing process. All these materials are then fed into the mixer for full mixing.

Once the mixing is complete, the concrete can enter the concrete mixer truck through the discharge port for transportation to where it is needed. Alternatively, the concrete can be discharged directly into the concrete pump for sale. The whole process of weighing, mixing and discharging is automatically controlled by software to ensure the production of high quality concrete.

Why choose a skip type mixing plant?

In fact, there are two common types of concrete mixing plants available in the market, namely belt conveyor type and skip type. The choice of which type depends mainly on your specific requirements.

The skip type concrete mixing plant is compact in design and has a small footprint. Therefore, if you have limited working space, skip type concrete mixing plant is a good choice.

The skip type concrete mixing plant is less costly compared to the belt conveyor concrete mixing plant. And due to its compact design, it can be transported in fewer containers, thus saving shipping costs.

In addition, the skip-type concrete mixing plant has a short assembly time and is easy to move between job sites. This makes it a more flexible concrete production plant for situations that require frequent relocation or temporary job sites.

As a concrete mixing plant manufacturer in China, ZOOMJO, we have sold our products to many countries, including Philippines, Indonesia, Thailand, Cambodia, Nepal, Rwanda, Ethiopia, Kenya, Peru, Chile, Ecuador and Bolivia. In these countries, ZOOMJO's concrete mixing plants have received wide recognition and good feedback from our customers.

The demand and use of concrete mixing plants may vary from country to country at the workplace. The following are some typical workplaces where ZOOMJO sells concrete mixing plants worldwide and their characteristics:

Skip-load concrete mixing plants: ZOOMJO recommends the JS series of twin-shaft concrete mixers, which are by far the most popular type of mixer. For some customers who need to produce high quality precast concrete, planetary concrete mixers are also an option. These mixers guarantee homogeneous mixing and quality control of the concrete, meeting the needs of different customers.

Cement feeding method: If bulk cement is not available on site, ZOOMJO offers mini silos and screw conveyors to feed the cement. This solution does not require a cement silo and is more flexible and convenient, adapting to the needs of various sites.

Installation time: The skip type concrete mixing plant has the advantage of a simpler structure compared to the belt conveyor type concrete mixing plant, so the installation time is shorter, usually only about 2 weeks to complete the installation and commissioning work. This makes it possible to better meet the needs of the site for projects with tight deadlines.

Quality assurance: ZOOMJO offers a 12-month warranty after installation and commissioning, providing our customers with a full range of after-sales services. This does not, of course, include damage to spare parts due to tearing and wear.

ZOOMJO adheres to a philosophy of high quality products and services. We believe that price should not be the only criterion for customers' choice, but more important is the perfect working performance and reliability of the equipment. ZOOMJO is committed to providing customers with high quality concrete mixing plants and looks forward to growing and developing together with them in future cooperation.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська