Workflow & Process Of Automatic Concrete Mixing Plant

Mixing plant is one of the common concrete equipment in the construction industry, which meets the needs of various concrete building construction through its efficient working process and precise mixing performance. Here is the process flow diagram of the mixing plant to understand the working principle of concrete mixing plant.

Ready-mix concrete mixing plant is a high-efficiency and low-consumption equipment with fast mixing speed and good performance. It is also equipped with intelligent control and automatic management functions that enable accurate measurement of raw materials and simple maintenance.

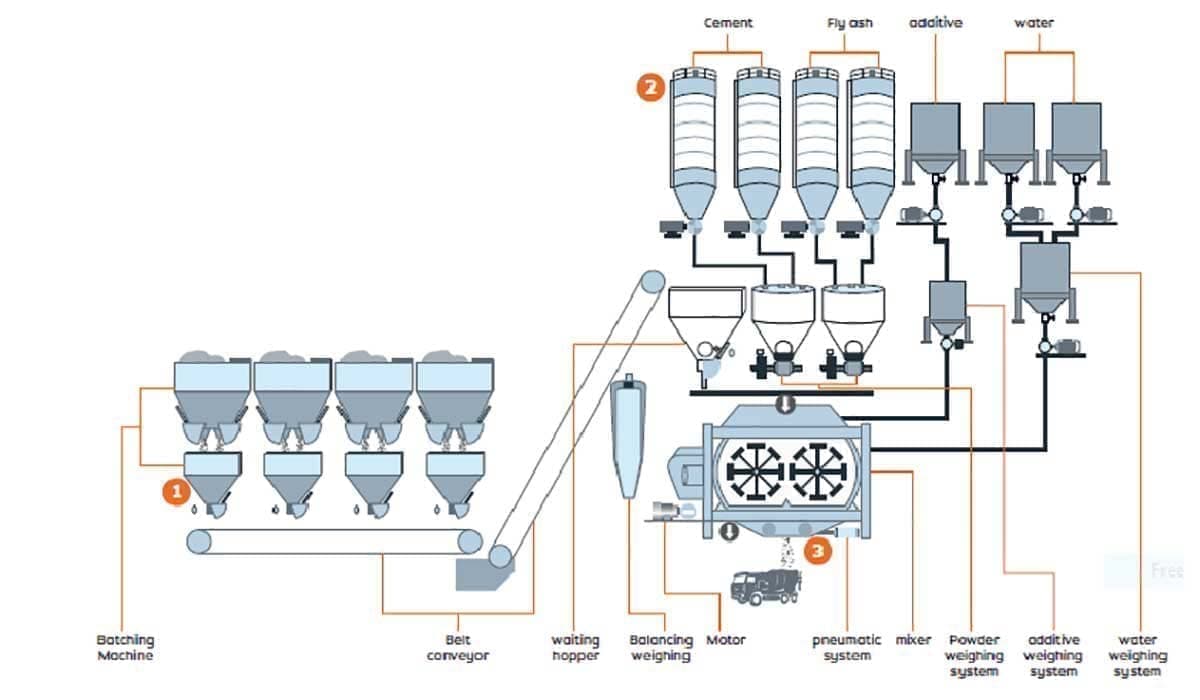

The process flow chart of a concrete mixing plant includes the following steps:

Material feeding: Concrete production requires raw materials such as aggregates, cement, water and additives. These materials are fed into the storage system of the mixing plant by different means. Aggregates are fed by wheel loaders, cement is fed by cement trucks, water is supplied by pumps and additives are supplied by additive pumps.

Material Measurement: Once all materials are prepared, performing material measurements is a critical step. To ensure accurate composition ratios, each raw material is measured by a separate measuring system. Aggregates and cement are measured by means of batchers, while water and additives are measured by means of their respective dosing hoppers.

Material transport: Different materials are transported in different ways. Aggregates are transported by belt or hopper elevator, cement by screw conveyor, water and additives by pump.

Material mixing: Various materials enter the concrete mixer and are mixed fully and evenly through the mixing shaft and blades. The mixer has a powerful mixing capacity and is able to mix the materials fully for about 60-70 seconds.

Concrete Discharge: After the concrete products are mixed, they are discharged to the waiting concrete mixer truck or concrete pump machine through the discharge gate under the mixing main machine and then delivered to the construction project site.

In order to automate the whole working process, the concrete mixing plant is equipped with an intelligent control system. The system is pre-programmed in an industrial computer in the form of a digital program with automatic monitoring, automatic alarm, automatic compensation and data storage. Before production, the operator only needs to enter the required concrete batching ratio parameters on the human-machine interface of the industrial computer and click a button to realize the complete process.

The workflow of the intelligent control system includes the following steps:

The industrial computer receives the initial data: the industrial computer receives the initial data from the human-machine interface, including the concrete batching ratio parameters, etc.

The computer starts the operation command: the computer starts the operation command according to the received data and starts the whole work process.

Material weighing: the computer calculates the digital information of various material weights and sends it to the PLC controller. The load cell of each material weighing system transmits the weighing data to the controller in real time.

Data comparison and control: The PLC controller compares the actual data with the preset data. When the weighing data reaches the preset data, the controller sends data to the pneumatic system in order to close the discharge door. At the same time, the controller controls the action of solenoid valve and motor to complete the mixing process according to the instruction of industrial computer.

During the whole working process, the sensor transmits real-time information of the weighing device and the mixer to the computer to monitor the weighing and mixing process. When the real-time data deviates from the preset value, the computer will automatically compensate. The operator can monitor the whole process in real time on a dynamic display in the control room.

The concrete mixing plant realizes the concrete production process through the combination and cooperation of several functional systems. The application of intelligent control system makes the concrete mixing plant work more efficiently and precisely. By understanding the process flow diagram of the mixing plant and the working principle of the control system, we can better understand the working process of the concrete mixing plant. We hope this article will help you to understand concrete mixing plant.

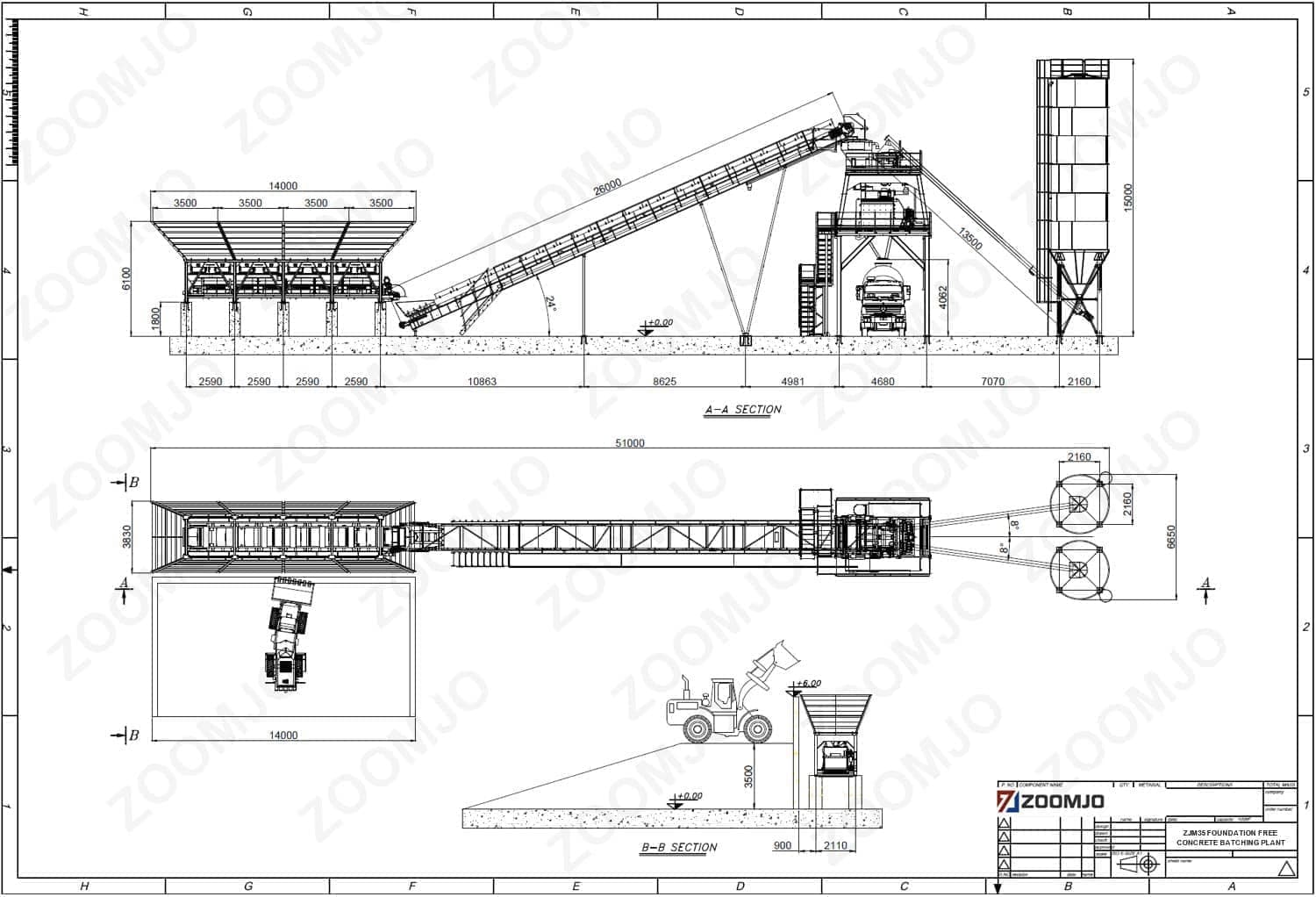

Whether it is a large infrastructure project or a small construction project, ZOOMJO concrete mixing plant equipment provides excellent performance and reliability. The wide range of products includes mobile mixing plants, stationary mixing plants and special customized equipment to meet different site and project requirements.ZOOMJO concrete mixing plant products use advanced automated control systems to ensure efficient and accurate production processes and minimize waste.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська