Automatic Dry Mortar Production Line

With the development of modern construction industry, automatic dry mortar production line has become an indispensable part of the construction industry as well as other related fields. This kind of production line is specially designed for producing various kinds of dry mortar, including masonry mortar, plastering mortar, thermal insulation mortar, anti-cracking mortar, self-leveling mortar, runway repairing mortar, highway repairing mortar, tile adhesive, interior wall decorative putty and paint, and so on. Fully automatic dry mortar production line is designed for enterprises with large quantity of dry mortar production demand, with the advantages of high efficiency, precision and convenience.

Automatic dry-mixed mortar production line: classification and characteristics

Automatic dry mortar production line can be divided into tower type automatic dry mortar production line, ladder type dry mortar production line and flat dry mortar production line according to the structure. According to the degree of automation, it can be divided into simple small mortar production line, fully automatic dry mortar production line, semi-automatic dry mortar production line. Among them, the full-automatic type has the highest production efficiency, which can greatly improve production efficiency and reduce labor costs.

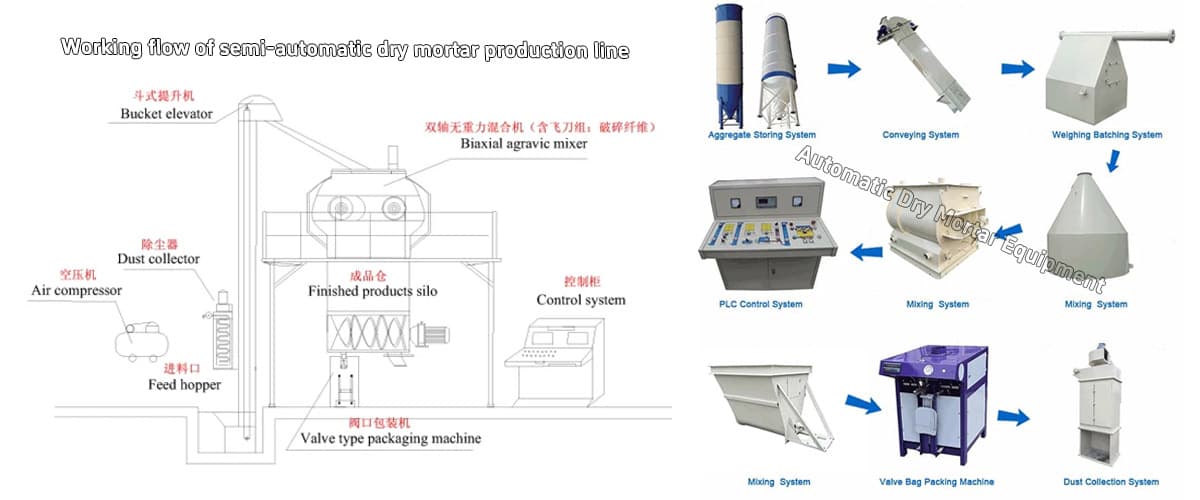

The working principle of automatic dry mortar production line

The working principle of automatic dry mortar production line is mainly to dry and sieve fine aggregate, inorganic binder, waterproof thickening material, mineral admixture and additives, and then mixed by mortar mixer according to a certain proportion. The final product is usually bagged or bulk, and can be used at the construction site by just adding water or other ingredients and mixing well.

Main components of automatic dry mortar production line

The automatic dry mortar production line is mainly composed of elevator, premixing silo, storage silo, cement silo, dry mortar mixer, finished product silo, packaging machine, dust collector and electric control cabinet. In addition, according to the actual needs of customers, sand drying system can be added.

Dry mortar equipment: advantages and options

Automatic dry mortar production line has significant advantages. Firstly, this equipment can significantly improve the production efficiency and reduce the labor cost. Secondly, the fully automatic production method ensures the consistency and precision of the product, which greatly improves the quality of the product. In addition, fully automatic dry mortar production line is easy to operate and maintain, with good stability and long durability.

When choosing automatic dry mortar production line, first of all, you should clarify your production needs, such as production scale, product type and so on. Secondly, you should consider the performance and quality of the equipment and choose the equipment with good reputation and widely used. Finally, factors such as the price and after-sales service of the equipment should also be considered.

Manufacturer of dry powder mortar production line

As an experienced manufacturer and supplier of dry mortar equipment, ZOOMJO not only provides advanced equipment, but also all-around services for customers. This includes site planning, equipment installation guidance and commissioning, personnel training, lifelong technical guidance and so on. At the same time, the company can also provide specific dry-mixed mortar formulations according to the specific needs of customers, to ensure that the production of mortar in line with the standards.

ZOOMJO dry mortar equipment has been exported to Vietnam, Ghana, Kenya, Cambodia, Algeria, Iran, Thailand, Russia, Pakistan, Indonesia, Peru, Philippines, Singapore and other countries.

How to choose the right model of dry mortar equipment?

In order to determine the required dry mortar equipment model, you need to consider the production capacity and the size of the factory area, and then choose the equipment structure according to the degree of automation. Finally, decide whether to buy sand dryer, packaging system and other auxiliary equipment according to the actual demand. Customers can consult the professional sales staff to get the site plan and three-dimensional drawings to meet their needs.ZOOMJO provides two types of dry mortar mixing plant, standard and customized, to meet the needs of different customers.

As a famous dry mortar plant manufacturer in China, ZOOMJO has won the trust of customers all over the world with its efficient, reliable and energy-saving products based on years of production and sales experience. Whether it is dry mortar mixing plant or other equipment, ZOOMJO is your reliable partner. If you are in need of dry mortar equipment, please feel free to contact us for a free consultation. We will provide you with professional solutions to help you achieve excellent results in production.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська