Dry Mortar Mixing Plant for Sale

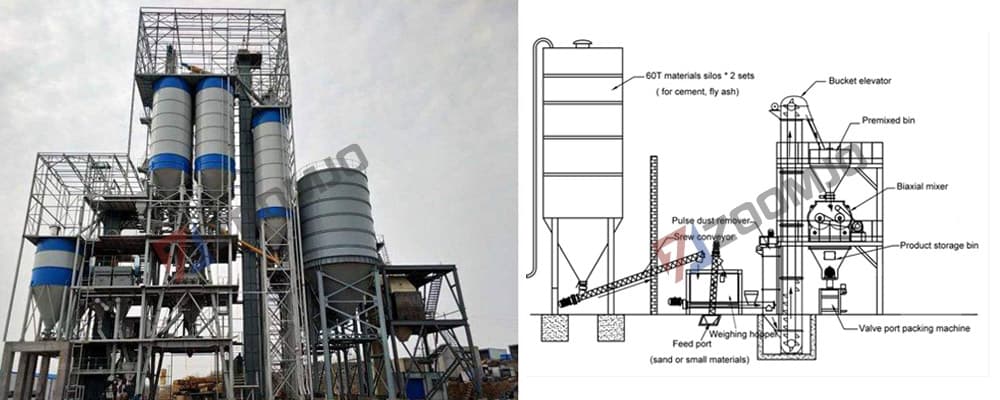

Dry mortar mixing plants are specialized in the production of various mortar mixes required for building construction, also known as polymer mortars. This versatile equipment is mainly used in applications such as masonry, plastering, insulation systems and interior decoration. Generally, a dry mortar production line includes an elevator, ready-mix silo, cement silo, dry mortar mixer, finished product silo, packaging machine, dust collector, electric control cabinet, and gas balance system.

The working principle of dry mortar mix plant:

The layout of the dry mortar mixing plant is usually of three types, such as plant layout, ladder layout and tower layout. The general production process includes the following steps:

a. Pre-treated raw materials are lifted to the top of the raw material silo, and then naturally flow out of the silo by the gravity of raw materials.

b. The raw materials are weighed, dosed and mixed to form the final product.

c. The whole production process is completed under the control of modern microcomputer control system, the operator only needs to specify the type and quantity of the product, the rest of the work is done by the automatic control system without manual intervention.

d. The fully closed production system ensures no dust pollution and protects the health of workers.

Types and features of dry mortar mix plant

According to different needs and investment budgets, there are three main types of dry mortar mixing plant:

1. Simple type: it consists of gravity mixer, dry powder silo and packing screw etc. Small investment, quick results, but limited output, labor intensity, suitable for initial investment is low.

2. Semi-automatic type: it consists of non-gravity mixer (with fly cutter), finished product silo, packaging machine, bucket elevator, pre-mixing silo, dust collector, pneumatic system, control system and so on. The investment is more, but the output is high, the working environment is good, and the expandability is strong, which is suitable for most investors.

3. Automatic type: It includes several systems, such as high efficient mixing system, storage system, conveying system, upgrading system, weighing system, premixing system, packing system, dust collector system, material level control system, alarm system, pneumatic system, machine control system and so on. The cost is higher, but the return rate is high, and it is suitable for medium cities and other areas with a better foundation for wall insulation.

Quality dry mortar mix equipment:

High-quality equipment usually has a modular structure, a capacity adapted to the market development and offers high accuracy of dosing, flexibility of use and easy expansion. Our company (ZOOMJO) adopts the leading technology in China, and not only takes full consideration of customers' needs, but also carefully develops a variety of equipment that ensures low cost, high mixing efficiency, full functionality, reliable performance and easy operation.

Equipment selection of dry mortar mix:

Drying system is the core of the whole dry mortar station, which determines the production efficiency. The heat source of drying equipment can choose hot air furnace or boiling furnace, and the specific choice depends on the local situation. The hot air furnace costs less but requires high quality coal to burn, while the boiling furnace costs more but can use inferior coal. Mixing systems are generally available in single-shaft pear blade and two-shaft gravityless options, each of which is suitable for different types of mortar production.

About ZOOMJO Dry Mortar mix Equipment Manufacturer:

ZOOMJO has won high praise from new and old customers for its high quality products, advanced technology, excellent standards and strict management services. We have abundant successful cases and our products are exported to overseas and loved by international customers. Our dry mortar station is made with first-class technology and trustworthy guarantee, which we prove with various certificates. We are committed to providing high quality guarantee and have been adhering to the original intention of being the best brand and dry mortar mix equipment manufacturer.

How to choose to buy dry mortar mix plant:

If you are interested in our products, please feel free to contact us, and we welcome new and old customers to visit our factory at any time. It is vital to choose a dry mortar plant with excellent quality and reasonable price among many brands, good equipment will bring substantial improvement to your work, speed up the work process and increase the production efficiency.

ZOOMJO is totally committed to providing users with satisfactory services and meeting your needs with reasonable prices and excellent product sales and services. Our products are known for their excellent quality and cost-effectiveness and have been sold to more than 100 countries and regions such as Philippines, Vietnam, Laos, Cambodia, Singapore, Zimbabwe and so on. We can supply dry mortar mixing plant, stationary concrete mixing plant, mobile concrete mixing plant, foundationless concrete mixing plant, concrete mixing pump, concrete tractor pump, self-mounted concrete mixer and other products to our customers.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська