Customized Concrete Batching Plants

What is a customized batching plant?

A custom concrete batching plant, also known as a tailor-made or custom batching plant, is a concrete production facility designed and built to meet the specific and unique requirements of a particular project or client. Custom batching plants offer the following advantages over standardized batching plants:

-

Highly specialized: Custom batching plants can be optimized to meet the individual needs and constraints of a specific application, maximizing productivity and concrete quality.

-

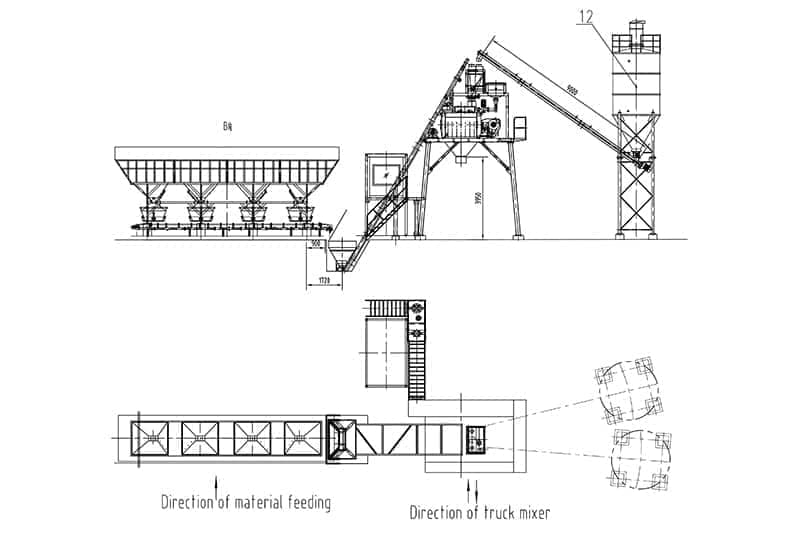

Flexible Layout: For projects with limited space or special site conditions, customized batching plants can be designed to meet these constraints, making the most of the available space.

-

Meeting Complex Requirements: Customized batching plants are particularly suited to large and complex projects, such as large infrastructure developments, where standard equipment may not be able to meet the specific requirements of the project.

Application scenarios for customized batching plants:

Large infrastructure developments such as highways, bridges, tunnels, etc.

-

Industrial and civil construction projects

-

Ready-mixed concrete production plants

-

Concrete product manufacturing plants

If you have any needs or ideas about customized batching plant, please feel free to contact our experts. We will provide you with professional consultation and tailor-made solutions.

Types of customizable concrete batching plants

With 30 years of experience in manufacturing concrete batching plants, ZOOMJO is committed to providing the ready-mix and precast industries with a full range of concrete batching plants and accessories to help you efficiently produce high quality concrete. Whether you are in the wet or dry mix business, for large or small projects, ZOOMJO has a quality batching plant to meet your needs.

ZOOMJO has a wealth of experience in designing and manufacturing customized batching plants, and can provide you with a full range of customized services, including: project demand analysis, program design, equipment manufacturing, installation and commissioning, after-sales service.

Advantages of ZOOMJO concrete batching plant:

-

Rugged metal structure: to ensure that the equipment is durable and able to withstand the harsh working environment.

-

High-quality components: the use of international famous brand components, stable and reliable performance, low maintenance costs.

-

Highest batching accuracy: Advanced weighing system and control technology ensure high batching accuracy and stable concrete quality.

-

Modern weighing system: Equipped with modern weighing system with load cell, the data is accurate and reliable, and the operation is more convenient.

-

Support customization: Various types of concrete batching plants can be customized according to your requirements to meet your individual needs.

Customized stationary concrete batching plants

ZOOMJO series stationary concrete batching plant adopts the most advanced technology, horizontal twin-shaft forced mixer with strong mixing capacity, uniform mixing and high output. Compact stationary modular structure, efficient transmission and easy maintenance greatly improve the durability and reliability of the plant. This series of stationary concrete mixing plant covers all outputs in concrete mixing industry (25m³/h, 25m³/h, 50m³/h, 60m³/h, 75m³/h, 90m³/h, 120m³/h, 150m³/h, 180m³/h).

Mobile Portable Concrete Batching Plant

Whether you need a temporary installation, a special project, or a permanent facility, our mobile concrete batching plants can meet your needs.ZOOMJO Mobile Concrete Batching Plants offer an affordable, reliable, and efficient solution to help you complete your project quickly.

Advantage:

-

Rapid Deployment: Deploys in just a few days, allowing you to start production immediately.

-

Affordable: Less expensive and more cost-effective than stationary concrete plants.

-

Flexible and convenient: Easy to move to different construction sites through containerized or integral transportation.

-

Adaptable: Small footprint, suitable for sites with limited space.

-

High-performance: Capacity ranges from 25 to 120 cubic meters per hour to meet the needs of different projects.

-

Reliability and durability: Heavy-duty frames and factory pre-assembled parts ensure the equipment is built to last.

-

Reduced Costs: Save on concrete transportation costs and increase project profitability.

Specification:

-

Production capacity: 25 cubic meters per hour - 120 cubic meters per hour

-

Models: Ramp Feeder, Ground Level Silo Models

-

Optional equipment: silos, storage bins and other auxiliary equipment.

-

Contact us today to find out how our mobile concrete mixing plants can help you improve project efficiency and profitability.

Customization of foundationless concrete mixing plant

Foundationless concrete mixing plant, also known as mobile concrete mixing plant, is a kind of concrete mixing plant that can be installed and used without a fixed foundation. It has the advantages of compact structure, flexible movement, quick installation, small footprint, etc. It is especially suitable for occasions of temporary concrete production.

ZOOMJO foundationless concrete mixing plant is especially suitable for temporary production in the construction of highways, railroads, bridges, water conservancy, etc. It can also be used in concrete product factories and commercial concrete mixing plants. We provide customized service, we can tailor the most suitable mixing plant solution for you according to your site size, production process, raw material proportion and other requirements.

Contact us today for a free consultation and customized quote!

Dry Concrete Batching Plant

ZJ series stationary dry batching plant adopts modular design, which can be customized and produced according to your specific needs, providing standard dry batching configurations ranging from 35 cubic meters per hour to 120 cubic meters per hour to meet your diversified needs. We also provide container transportation services to facilitate the transportation and installation of your equipment.

Advantage:

-

Affordable: Low installation costs and low operating costs bring you a cost-effective option.

-

Reliable and Durable: The use of well-known brand components and structural design in line with international standards ensures the reliability and durability of the equipment.

-

Quick installation: Modular design, easy and quick installation, saving your construction time.

-

Convenient Maintenance: Easy to maintain, reducing your operating costs.

-

Durable: Carefully designed and manufactured to ensure a long service life.

ZJ series stationary dry batching plant is your ideal solution for concrete production. Contact us today for more information and a quote.

Wet Concrete Batching Plants

ZOOMJO stationary wet batching plants are modular in design and can be customized for production according to your specific needs, offering standard wet batching configurations ranging from 25 m3 to 240 m3 per hour to meet your diverse needs. We also offer containerized shipping services to facilitate the transportation and installation of your equipment.

Advantage:

-

Excellent quality: The use of well-known brand components and structural design in line with international standards ensures the reliability and durability of the equipment, bringing you long-lasting and stable production performance.

-

Easy Maintenance, Affordable: Easy maintenance reduces your operating costs and allows you to enjoy a more affordable production experience.

-

Tailor-made to meet your needs: A variety of layout options are available, which can be flexibly customized to meet your individual needs according to your site and production requirements.

-

Efficient production, unimpeded: Strong production capacity to meet the needs of high-volume concrete production, helping your project move forward efficiently.

Cost of a customized concrete batching plant

The price of a concrete batching plant is one of the main considerations when starting a project that requires concrete. The price list is ZOOMJO concrete batching plant for your reference:

-

zj-25 ~ zj-240 $28000 - $128000

-

ZJY-25 ~ ZJY-120 $8000 - $108000

-

zjm-25 ~ zjm-120 $15000 - $98000

But it doesn't mean that you can buy the concrete mixing plant mentioned above with such a price. Because there are many factors affecting the price list, such as model, type, configuration, promotion, negotiation, shipping cost, manufacturer and so on. Therefore, usually many concrete batching plant manufacturers give the price range of concrete batching plant.

Factors affecting the price of customized concrete batching plant

Concrete batching plant is a large-scale concrete production equipment, the price of which not only depends on the cost of the plant itself, but also includes the costs associated with it before, during and after the investment. Here are some of the main factors that affect the price of customized concrete batching plant:

1. the price of the equipment itself

This is the most basic influencing factor, which mainly depends on the concrete mixing plant supplier, manufacturer, parts used, branded accessories, steel, coating process, etc.

2. Model

The model of a concrete batching plant represents its hourly output, the higher the output, the higher the price. Common models of stationary concrete batching plants include ZJ-25, ZJ-35, ZJ-50, ZJ-60, ZJ-75, ZJ-90, ZJ-120 and ZJ-180, and the price generally follows the pattern of ZJ-180 > ZJ-120 > ZJ-90 > ... > ZJ-25. > ZJ-25.

3. Type

The type of concrete mixing plant also affects the price. Common types include:

-

Stationary concrete mixing plant: relatively low price, suitable for concrete production in long-term fixed locations.

-

Mobile Concrete Batching Plants: Compact and easy to move, suitable for concrete production in temporary or mobile locations.

-

Foundationless Concrete Batching Plant: No need to build a foundation, easy to install, suitable for site conditions.

-

Dry Concrete Batching Plant: Produces dry concrete, suitable for long-distance transportation or ready-mixed concrete.

-

Wet Mix Concrete Batching Plant: Produces wet concrete, suitable for on-site pouring.

4. Configuration

The price of different configurations of concrete batching plants varies greatly. The price of mixing plant with simple configuration is much lower than that of mixing plant with standard or high-end configuration. Therefore, project requirements and duration should be clearly defined when requesting quotes in order to get a more accurate price quote. Configuration factors mainly include:

-

Aggregate weighing system: single bin, double bin, multi-bin, etc.

-

Cement weighing system: powder, liquid, etc.

-

Additive weighing system: pumping type, gravity type, etc.

-

Mixer: type, capacity, etc.

-

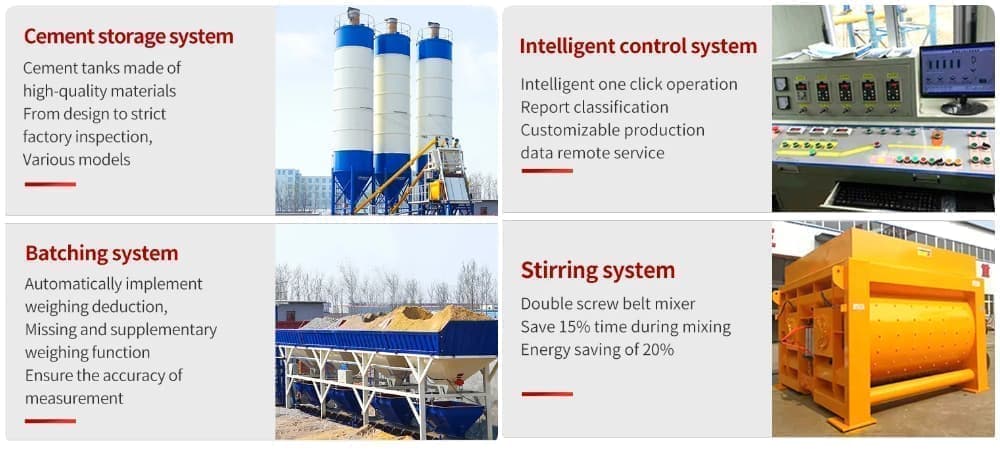

Control system: manual, semi-automatic, automatic, etc.

5. Additional functions

-

Some optional features can increase the overall cost of the concrete mixing plant, for example:

-

Automation system: can increase productivity and reduce labor cost.

-

Computer control system: can realize fine control and data analysis.

-

Advanced mixing technology: can improve concrete quality and reduce production cost.

6. Geographical location

Local laws and regulations, taxes and transportation costs can also affect the final price.

Customizable Concrete Batching Plant Equipment List

A customizable concrete batching plant consists of a variety of components that can be tailored to meet the specific needs of a particular project. Here are some common customizable concrete batching plant equipment:

-

Aggregate Weighing System: Used to weigh aggregates to ensure the accuracy of concrete ratios.

-

Cement Weighing System: Used to weigh cement to ensure the accuracy of the concrete mix.

-

Water weighing system: Used for weighing water to ensure the accuracy of concrete proportion.

-

Admixture weighing system: It is used to measure the dosage of admixtures, such as water reducer, retarder, air-entraining agent, etc.

-

Conveyor: It is used to convey the aggregate, cement, water and admixture to the mixer.

-

Mixer: It is used to mix the aggregate, cement, water and admixture into concrete evenly.

-

Control system: Used to control the equipment of the batching plant and monitor the batching process.

-

Aggregate silo: for storing aggregates.

-

Cement silo: for storing cement.

-

Water tank: for storing water.

-

Admixture storage tank: for storage of admixtures.

-

Waste conveying system: for conveying the waste material to the designated place.

-

Dust collection system: for collecting dust generated during the production process.

Adjustable configurations are as follows

-

Concrete mixer: Single shaft, double horizontal shaft, twin screw horizontal shaft, Servomax concrete mixer, planetary concrete mixer, etc;

-

Cement silos: with or without, simple or multiple configurations;

-

Batching machine: two, three, four optional;

-

Hopper lifting: hopper or belt conveyor

How to get a good price for concrete mixing plant?

Buying a concrete batching plant is a major investment that requires careful decision making to get the best price. Here are some key strategies:

1. Define your needs and set a budget

First, determine your project needs and budget, including output, type, configuration and price range. Understanding your needs will prevent you from wasting money on unnecessary configurations.

2. Research extensively and compare suppliers

Research multiple suppliers and compare their reputation, experience, customer reviews and credentials. Request detailed quotes and compare equipment, services and costs, including installation, transportation, training and warranties.

3. Negotiate aggressively for a favorable deal

Don't hesitate to negotiate better prices with suppliers. Provide information on competitive quotes and express willingness to buy. Negotiate payment, delivery time and warranty coverage.

4. Focus on Total Cost of Ownership (TCO)

In addition to the initial price, consider the long-term costs of maintenance, spare parts, labor and energy. Choose energy-efficient equipment and consider the after-sales service and warranty offered by the supplier.

5. Consider used or refurbished equipment

When budget is limited, consider used or refurbished equipment, which is less expensive and reliable. Check the condition of the equipment, maintenance records and warranty policies at the time of purchase.

6. Seek government subsidies or incentives

Some regions may offer subsidies or incentives for the purchase of energy efficient or environmentally friendly mixing plants. Learn about local policies and apply for available financial assistance.

7. Attend industry events and trade shows

Attend concrete mixing plant industry events and trade shows to get the latest product information, meet suppliers, and learn about potential discounts or incentives.

8. Build long-term relationships

Establishing a long-term relationship with a reputable supplier can result in preferential pricing, priority service and customized solutions. Maintain good communication and timely payment to consolidate the relationship.

Remember: compare prices and negotiate smartly to get the best price and cost-effective concrete mixing plant!

ZOOMJO: Your reliable partner for concrete batching plants.

Superior quality, worry-free use

ZOOMJO concrete batching plant is made of high quality materials and advanced technology, durable and excellent performance. ZOOMJO products have passed ISO 9001 quality management system certification, providing you with reliable quality assurance.

Rich experience, professional service

With more than 30 years of experience in the industry, ZOOMJO has accumulated profound technical strength and rich practical experience. According to your specific needs, we can provide you with professional solutions and perfect pre-sale, sale and after-sale service, so that you have no worries.

Flexible customization to meet the needs

ZOOMJO provides customized batching plant solutions to meet your unique needs. We can customize the most suitable batching plant solution for you according to your site size, production process, raw material proportion and other requirements.

Successful cases, outstanding reputation

ZOOMJO has many successful projects in various industries. Our products and services have been highly evaluated by our customers.

Choosing ZOOMJO means choosing reliability. Contact us today to learn more and get a free consultation on customized concrete batching plants!

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська