Batching Plant Working Principle

Concrete batching plant is an indispensable equipment in modern construction projects, which can efficiently mix cement, sand, stone, water and other raw materials according to the precise proportion to produce concrete that meets the project requirements. This article will discuss the working principle of concrete mixing plant, from the overall structure to the specific process, so that you have a comprehensive understanding of this equipment.

Working Principle

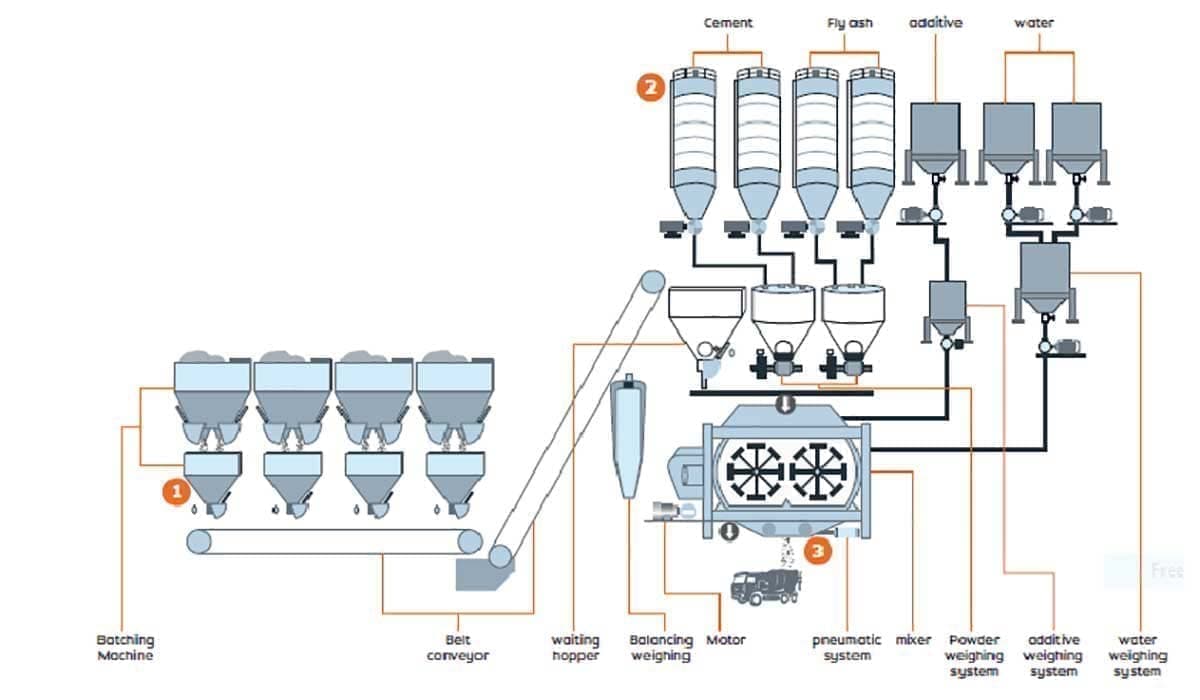

The working principle of concrete batching plant mainly depends on its internal batching system, mixing system and conveying system. The batching system is responsible for accurately weighing various raw materials (e.g. cement, fly ash, sand, etc.) in accordance with the set ratio, and then feeding them into the mixing system. Through the high-speed rotating mixing blades, the mixing system fully mixes the raw materials with water to achieve a uniform and consistent result. Finally, the evenly mixed concrete is transported to the concrete truck through the conveying system and transported to the construction site.

Workflow Process

1. Batching

According to the requirements of concrete proportioning, the required raw materials such as cement, sand, stone, etc. are accurately weighed through the measuring device and then fed into the concrete mixer according to a certain proportion. The weighing and conveying of each material is accurately controlled by the control panel to ensure the quality and consistency of the concrete.

2. Mixing

In the concrete mixer, the raw materials are mixed with water and fully stirred by the high-speed rotating mixing blades to achieve a uniform and consistent concrete. The mixing time is set by the control system to ensure consistent quality of each batch of concrete.

3. Conveying

The mixed concrete is transported to the concrete truck through the conveying system (such as conveyor belt, screw conveyor or concrete pump). The design of the conveying system ensures that the concrete does not separate during transport and maintains its uniformity.

4. Transport and unloading

The concrete transporter transports the concrete to the construction site and unloads it from the transporter by means of a hydraulic unloading system for use in the construction.

Main components

A concrete batching plant usually consists of the following main components:

-

Aggregate silo: Used to store aggregates such as sand, stone, etc., which are transported to the weighing device via a conveyor belt as required.

-

Cement weighing hopper: Used for storing and weighing cement to ensure accurate cement dosage for each batch of concrete.

-

Aggregate weighing hopper: Used for weighing aggregates one by one and discharging the aggregates through pneumatic cylinders for further processing.

-

Twin-shaft mixer: the core component of the concrete batching plant, responsible for mixing all ingredients evenly.

-

Control panel: controls the entire batching and mixing process, ensuring fast and accurate measurement of the components and producing high quality concrete.

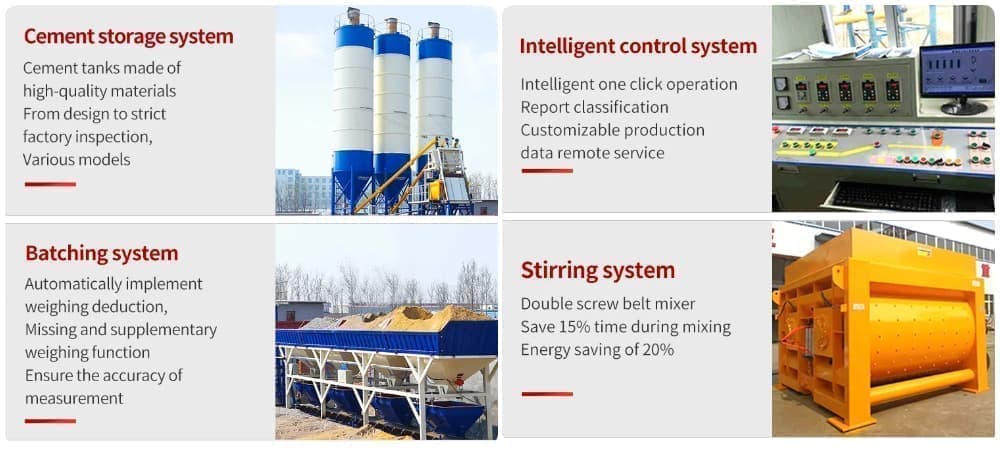

Modern concrete batching plants can also be equipped with advanced automated control systems capable of achieving the following functions:

-

Accurate batching: through advanced sensors and instruments, each ingredient is measured accurately to ensure accurate mix proportions.

-

Automated operation: The control system manages the entire batching process, including aggregate loading, weighing, mixing and unloading, reducing human error and improving operational efficiency.

-

Real-time monitoring: the system monitors key parameters such as material flow rate, mixing time and temperature in real time to ensure concrete quality.

-

Error prevention and correction: The system is equipped with an error detection mechanism that automatically identifies and corrects problems in the batching process, preventing the production of substandard concrete.

-

Data Recording and Reporting: Records the production data of each batch of concrete for quality control analysis and process optimisation.

Concrete batching plant realises large-scale and continuous production of concrete through accurate batching, efficient mixing and flexible conveying. Its working principle may seem simple, but it involves several complex engineering issues. With the continuous progress of science and technology, the degree of automation and production efficiency of concrete mixing plant will continue to improve, providing more high-quality and efficient services for the construction industry.

Concrete Batching Plant Manufacturer

ZOOMJO is a professional concrete plant manufacturer with 29 years of experience in providing customers with comprehensive concrete production solutions. Our product line covers a wide range of concrete batching plants to meet projects of different sizes and needs:

Our plants are available in a wide range of capacities, from 25m³/h to 240m³/h, and can be customised according to customer requirements. ZOOMJO batching plant adopts advanced technology to ensure the stable and reliable quality of concrete. In addition to the mixing plant, we also provide matching concrete equipment, such as: concrete mixer, concrete mixer pump truck, concrete trailer pump truck, self-loading concrete mixer truck.

Why choose ZOOMJO?

-

Customised Solutions: The most suitable concrete mixing plant for you according to your project requirements.

-

Advanced Technology: Adopting intelligent batching system and high efficient mixing system to ensure stable and reliable quality of concrete while reducing production cost.

-

Modular: Modular design, easy to install and maintain, and reduce operating costs.

-

Environmentally friendly: Adopting energy-saving and environmentally friendly materials and technologies to reduce the impact on the environment.

-

Full Service: Provide full process support from equipment selection, installation and commissioning to after-sales service.

ZOOMJO's products have been sold to 105 countries and regions, and have won widespread trust. With 50,000 square metres of factory area, we have advanced production scale and capacity. We are committed to providing customers with efficient and reliable concrete production solutions, and are equipped with a professional R&D team and senior engineers to ensure product quality and technological innovation.

If you need more information about concrete mixing plant, please feel free to contact us. ZOOMJO's professional team will provide you with professional consultation and customised services.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська