Large Concrete Mixers for Sale with Factory Price

A concrete mixer is a machine that evenly mixes aggregates such as cement, sand or gravel and water to form concrete. Large concrete mixer mainly refers to the concrete mixer with capacity more than 500L.

Application of Large Concrete Mixer

Large concrete mixer is mainly used for mixing plastic concrete, dry concrete, lightweight aggregate concrete and all kinds of mortar, which is an indispensable concrete preparation equipment in construction projects. Large concrete mixer is widely used in large-scale construction projects, such as high-rise buildings, large bridges, water conservancy projects and so on.

Types of Large Concrete Mixer

In the field of construction, large concrete mixer is an important equipment that can effectively mix a large amount of concrete. Among these mixers, three types are the most important: drum concrete mixers, twin-shaft concrete mixers, and self-loading concrete mixers. Each type has its own advantages and disadvantages and is suitable for different construction projects.

Drum Mixers

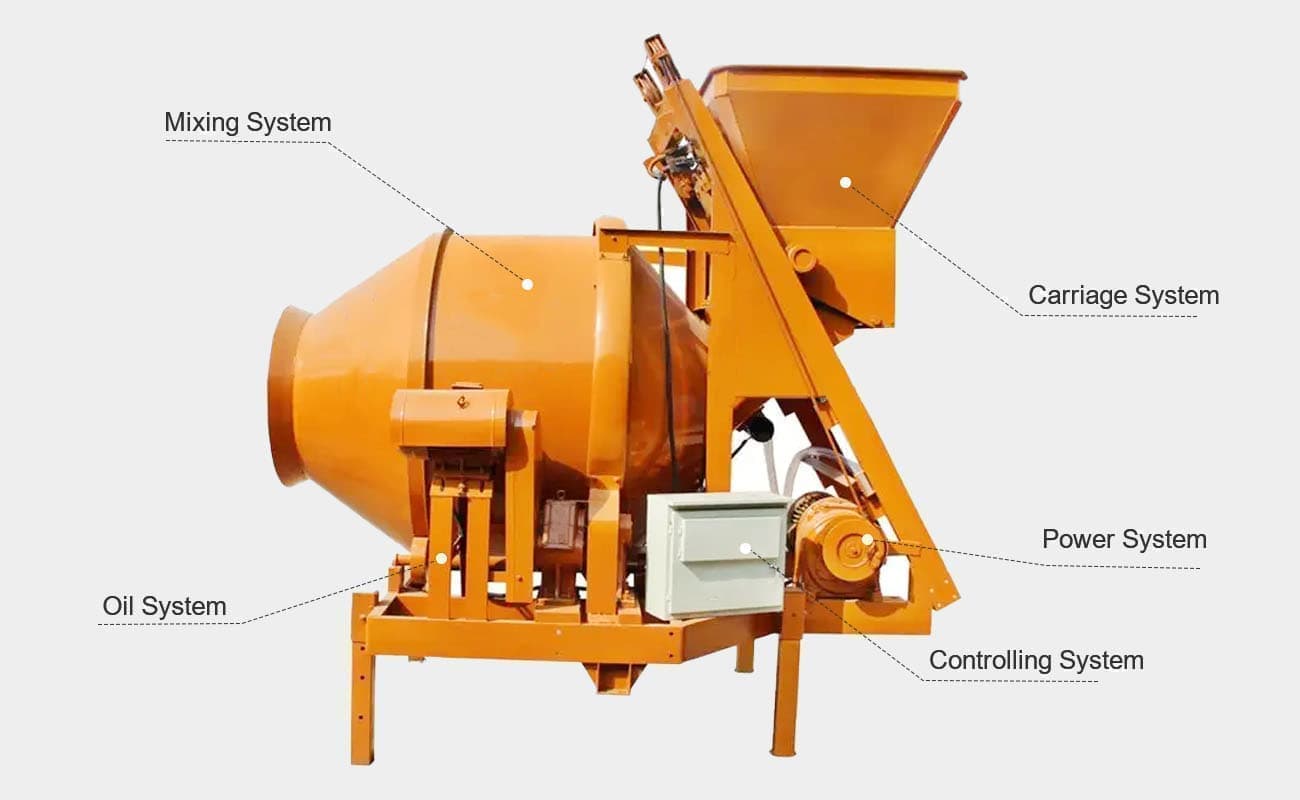

The drum mixer is the most common type of large concrete mixer and consists of a rotating drum that harmoniously mixes the concrete components. This type of mixer is simple to operate and easy to use. In addition, they are relatively inexpensive compared to their counterparts. However, for projects that require the production of high-quality concrete or precise mixing ratios, drum mixers may seem overwhelming. In addition, they have relatively slow mixing speeds.

Our drum concrete mixers are divided into two types: JZR series diesel concrete mixers and JZM series electric concrete mixers. JZR series diesel concrete mixers are powered by diesel engines and are suitable for outdoor construction sites with strong power, simple operation and easy maintenance, etc. JZM series electric concrete mixers are powered by electric motors and are suitable for indoor construction sites with low noise and pollution. JZM series electric concrete mixer adopts electric motor as power and is suitable for indoor construction site, featuring low noise, low pollution and energy saving. Both series of mixers adopt forced mixing method with good mixing effect and are suitable for various concrete projects.

Advantages of drum mixer

1. drum mixer adopts forced mixing mode, the mixing blade rotates at high speed in the mixing cylinder, which can mix the raw materials such as cement, sand, stone and so on, and ensure the uniformity of concrete.

2. the operation of drum mixer is simple, only need to manually load the raw materials into the mixing drum and start the mixer, no need for professional operation.

3. the structure of drum mixer is simple, easy to maintain, can reduce the cost of use.

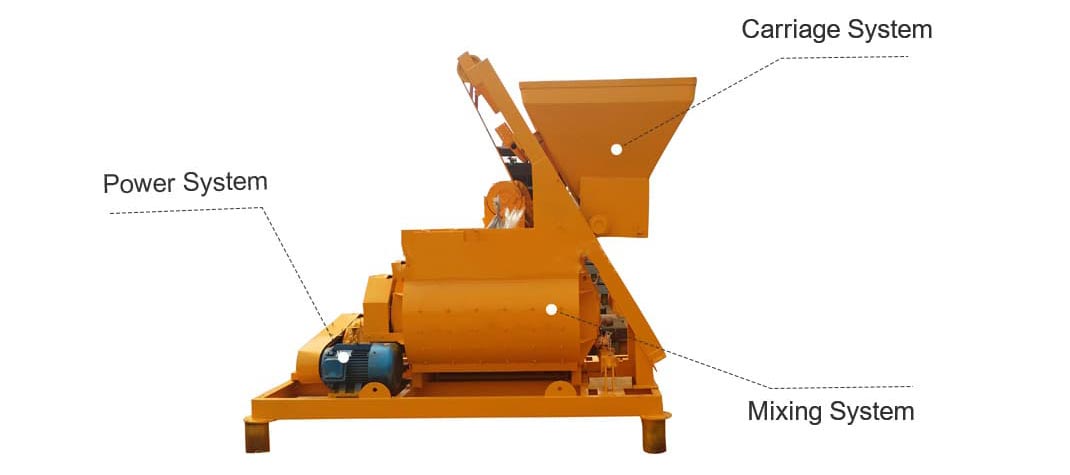

Twin Shaft Concrete Mixer

Known for its excellent mixing efficiency and resulting uniformity, the Twin Shaft Concrete Mixer features two horizontal shafts with multiple mixing blades that move in opposite directions to ensure a thorough mixing of the concrete components. The ability to handle a wide range of concrete types, including high-strength and self-compacting concrete, is a significant advantage of twin-shaft mixers. However, the complex design of twin shaft mixers makes them more expensive than drum mixers and requires more thoughtful maintenance.

We produce a wide range of twin shaft concrete mixers, including JS750, JS1000, JS1500, JS2000, JS3000, etc., to meet the needs of projects of different scales.

The advantages of twin shaft mixer are mainly reflected in the following aspects:

1. the mixing effect of twin-shaft mixer is good, it can mix cement, sand, stone and other raw materials evenly to ensure the quality of concrete.

2. The double shaft mixer has a large mixing capacity at one time, which can meet the concrete demand of the construction site and improve the construction efficiency. For large-scale projects, twin-shaft mixer is the ideal choice.

3. the structure of the twin-shaft mixer is simple, easy to disassemble and clean, easy to maintain, which can reduce the cost of use.

Self-loading Concrete Mixer

Self-loading concrete mixer refers to the concrete mixer with the functions of loading, mixing, weighing and discharging, etc. The loading device can load the raw materials such as cement, sand and stone into the mixing drum automatically, the mixing device can mix the mixture forcibly, the weighing device can accurately weigh the mixture, and the discharging device can discharged the concrete out of the mixing drum.

ZOOMJO self-loading concrete mixer has various models, among which ZC-1.2, ZC-1.8, ZC-2.6, ZC-3.5, ZC-4.0, ZC-5.5 are six common models. These six models have a mixing capacity of 1.2, 1.8, 2.6, 3.5, 4.0 and 5.5 cubic meters at one time, which are suitable for the needs of projects of different scales.

The advantages of self loading concrete mixer are as follows:

1. Self-loading concrete mixer can automatically complete the concrete batching, mixing and transportation processes, saving a lot of labor costs.

2. Self-loading concrete mixer can be flexibly deployed according to the conditions of the construction site, which is suitable for various construction environments.

3. Self-loading concrete mixer can quickly complete the production of concrete according to the needs of the construction site and improve the construction efficiency.

How to choose large concrete mixer?

When choosing a large concrete mixer, the following factors should be considered according to the construction needs:

1. Mixing volume is the primary factor for choosing large concrete mixer, and a suitable mixing volume should be chosen according to the construction needs. Generally speaking, the larger the mixing volume, the more mixing volume at one time, which can meet the construction needs of large-scale projects.

2. There are three types of large concrete mixers: horizontal twin-shaft mixer, horizontal single-shaft mixer and vertical mixer. Horizontal twin-shaft mixer is the most common type of large concrete mixer, which is characterized by large mixing volume, strong mixing performance and sturdy structure. Horizontal single-shaft mixers are characterized by simple structure, easy operation and relatively low price. Vertical mixers are characterized by a small footprint and can be used in narrow spaces.

3. The configuration of large concrete mixer mainly includes mixer, batching machine, cement silo, sand silo, stone silo, discharging machine and so on. According to the construction needs to choose the appropriate configuration.

4. The price of large concrete mixer mainly depends on the mixing volume, mixer type, configuration and other factors. Generally speaking, the larger the mixing volume, the more complex the mixer type, the higher the configuration, the higher the price.

Maintenance and care of large concrete mixer

Large concrete mixer is an indispensable equipment in construction projects, and its normal use directly affects the quality of concrete and construction progress. Therefore, the maintenance and repair of large concrete mixer is crucial.

The maintenance of large concrete mixer mainly includes routine maintenance and regular inspection. Daily maintenance should pay attention to check whether the equipment is intact, and operate according to the instructions; regular inspection should pay attention to check whether the various parts of the equipment are normal, and carry out the necessary lubrication, repair and adjustment.

By strengthening the maintenance and repair of large concrete mixer, it can effectively improve the use efficiency and service life of the equipment, reduce the operating costs and ensure the smooth progress of the construction.

ZOOMJO large concrete mixer manufacturer

ZOOMJO is a professional manufacturer of large concrete mixer, with strong technical research and development team and rich experience in manufacturing. Our products sell well all over the world and are trusted by new and old customers.

We participate in international construction machinery exhibitions from time to time to show our large concrete mixers, concrete pumps and concrete mixing plant solutions to customers.ZOOMJO products have passed many international certifications and are favored by the international market for their high cost performance. Our products have been sold to more than 105 countries including Philippines, Indonesia, Malaysia, Singapore, Sri Lanka, Kazakhstan, Uzbekistan, Russia, Ukraine, Ethiopia, South Africa, Nigeria, Jamaica, Dominica, Australia and so on.

If you are interested in any of our large concrete mixer products, please contact us and we will give you a detailed reply within 24 hours. You can also call us directly, we are at your service 24/7!

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська