How To Select Suitable Concrete Pump For Your Work?

Nowadays, concrete pumps are widely used in almost all concrete construction. 1933, the United States began to use hydraulic piston pumps and steel pipes to pump fresh concrete. Subsequently, this method has been continuously developed and improved for pumping various types of concrete, shortening pumping time and extending pumping distance.

The principle of concrete pump

The working principle of the concrete pump is based on double-cylinder hydraulic piston technology. When the hopper is loaded with concrete, one piston draws in the concrete and pushes it out through the steel pipe, while the other piston draws the concrete from the hopper and pushes it after the first piston. The pushing cylinder and the cylinder that sucks up the concrete are switched by means of a control valve.

Concrete pumps are usually divided into two types as follows:

Stationary concrete pumps: These pumps are powered by electricity or fuel and can be mounted on the ground or loaded on a truck. The site engineer needs to plan and prepare the location of the piping and pump in advance to ensure smooth pumping operations and to reduce pipework. The advantage of stationary concrete pumps is that they have a wide range of pressure capacities, which is important in high-rise construction.

Mobile Concrete Pumps / Concrete Pouring Booms: These pumps are mounted on trucks, making them easier to move. Mobile concrete pumps are easy to operate. Boom pumps are typically rented for $150 to $200 per hour, slightly more than stationary pumps. However, using this type of pump reduces scaffolding work for steel pipes, which is a huge advantage because the pumping action can cause the support structure to fail. The use of a pump truck allows for accurate concrete delivery to the target location compared to a stationary pump with separate piping. Pumps are typically equipped with 4-inch diameter piping and boom lengths ranging from 20 to 70 meters.

Before choosing the right concrete pump, the following points need to be considered:

Mix ratio characteristics: Consider increasing the slurry content and slump to improve pumping performance. Adding fly ash is an economical way to improve pumpability, but its effect on compressive strength needs to be calculated separately.

Site conditions and piping settings: If a five-story building needs to be poured, a concrete pump with sufficient pressure capacity should be selected. Factors such as horizontal distance, number of bends and pipe diameter can also add additional pressure requirements. The site engineer needs to select the appropriate location to place the pump, which should have accessibility, ventilation and lighting, and if a pump truck is used, enable it to cover the maximum area.

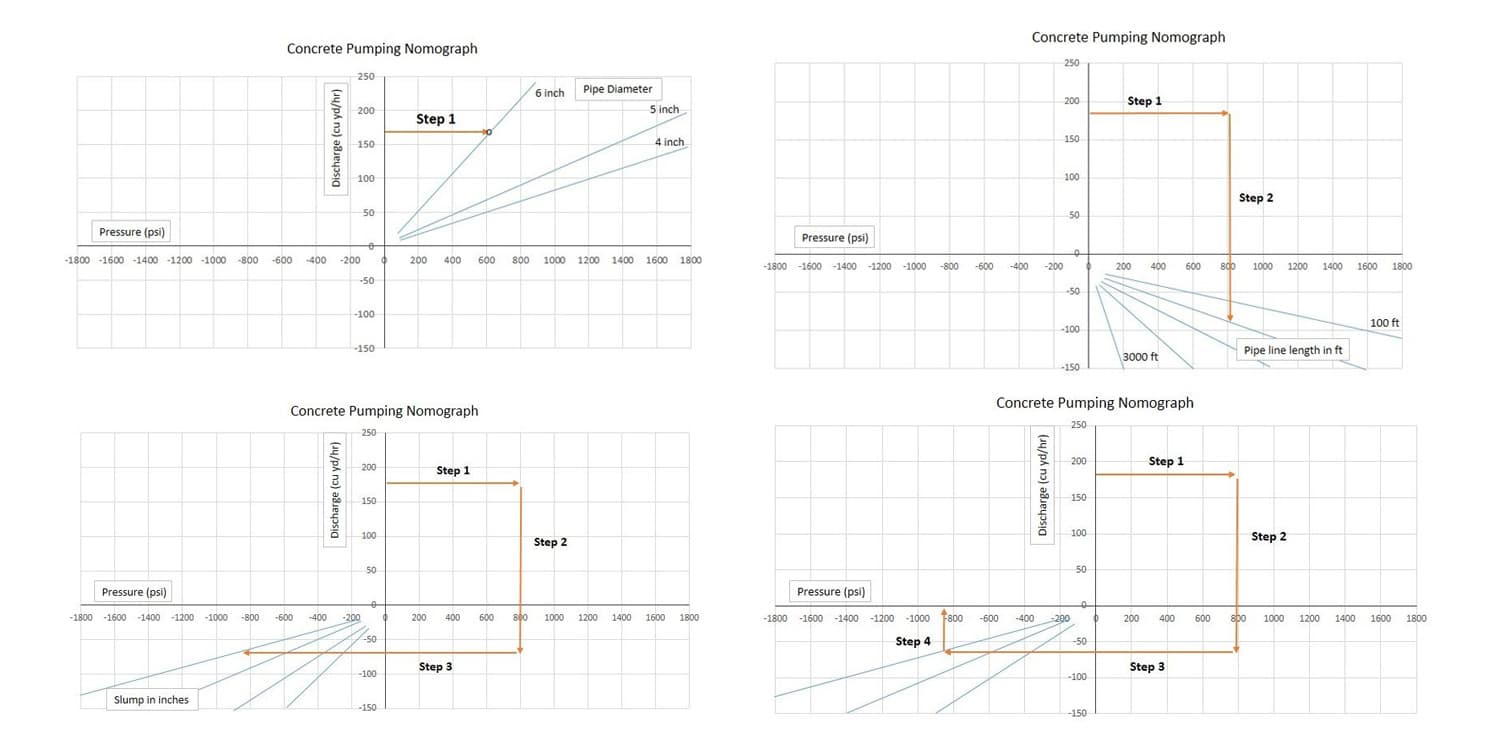

Use Nomograph: Nomograph is a tool used to calculate the required pumping capacity, incorporating factors such as displacement, slump and pipe length. Use the tables provided by ACI (American Concrete Institute) to calculate the required pumping pressure.

Select location and pipe setup

Draw a horizontal line starting from the discharge rate and find the point where it intersects the available steel pipe diameter.

Draw a vertical line from that point to reach the corresponding pipe length.

Draw another horizontal line from the point where the pipe length intersects and continue up to the part where the slump value is located.

Find the required pump pressure based on the slump available in the field. Adjust according to the correction and height difference of the pipeline.

Calculate the required pressure increase according to the following rules:

When the discharge is less than 55 m3 /hour, increase by 145 psi.

Increase 220 psi when discharge is greater than 55 cfm.

Increase vertical pressure by 11 psi for every 10 feet of rise.

Add 15 psi for each 90° bend and 7 psi for each 45° bend.

Add 22 psi for each additional 10 feet of rubber hose length.

Add up all the increased pressures and add 10% of the average pressure loss.

When using a concrete pump, consideration needs to be given to the safety of the pump and the operator:

Choose a well-lit and appropriate location for the pump and ensure proper ventilation.

Always be aware of the power lines above the work area.

Hire trained and experienced operators.

If using a pump truck, the operator should have good eyesight to read hand signals.

Use signalers, flags, lights and walkie-talkies for communication.

Do not increase pressure during blockage.

Fill the hopper at the end of each truck and pump a small amount to avoid the concrete from hardening before the next truck arrives.

Prepare adequate supports to withstand the weight and bumps of the pipe.

Record necessary information during the pouring process, such as batching time, placement time, placement location, slump and temperature.

Control the noise during the pouring process.

Repair and maintenance of the pump, using cleaning sponge balls to remove all concrete residues from the pipes.

Concrete pump brand manufacturers

ZOOMJO concrete trailer pumps and concrete mixer pumps are indispensable and important equipment on modern construction sites. Their outstanding performance and versatile design make construction work more efficient and convenient.

The ZOOMJO concrete trailer pump has a powerful concrete conveying capacity that enables it to quickly and efficiently deliver concrete to the desired location on the construction site. With its advanced hydraulic system and efficient pumping unit, it is able to cope with various construction environments and conditions, ensuring continuous supply and stability of concrete.

The ZOOMJO concrete mixer pump is also a powerful machine. It not only mixes concrete, but also performs integrated mixing and conveying operations. This makes the concrete mixing and conveying process more efficient and seamless, which greatly improves the efficiency and quality of construction.

ZOOMJO concrete trailer pump and concrete mixer pump are designed to be easy and user-friendly to operate, equipped with advanced control system and operation interface. The staff can set up and monitor various functions through simple operations to ensure the safety and smoothness of the construction process.

As a professional manufacturer, ZOOMJO has advanced production equipment and technical team. They are committed to continuously improving and optimizing product design to meet the diverse needs of their customers. Whether it is a large infrastructure project or a small construction project, ZOOMJO's concrete pumping equipment provides efficient pumping solutions.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська