Concrete Batch Plant Work

A concrete batching plant, also known as a concrete plant, is a large piece of equipment designed to produce concrete. It is capable of mixing aggregates, sand, cement, water and various additives together in precise proportions to create concrete of consistent quality. The emergence of this equipment has greatly improved the efficiency and quality of concrete production.

Before understanding how a concrete mixing plant works, you first need to familiarise yourself with its basic components and structure.

Components of a concrete mixing plant

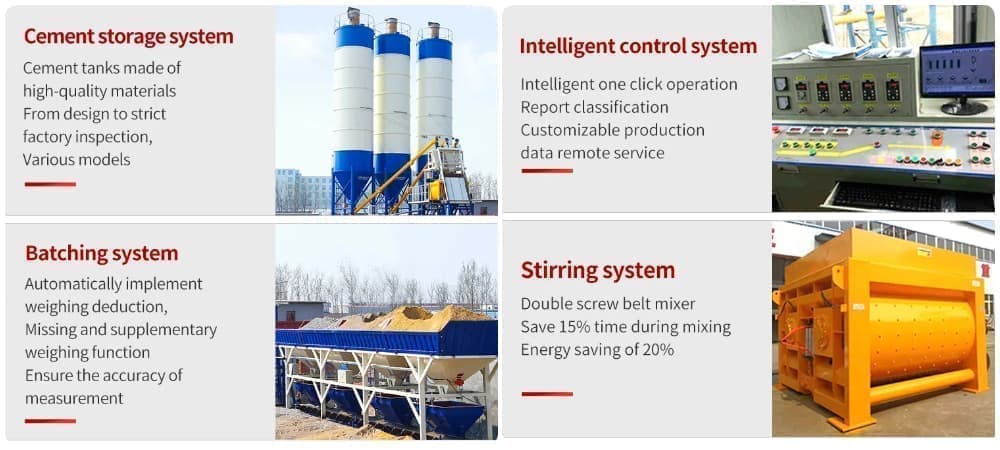

The concrete mixing plant is mainly composed of the following parts:

-

Aggregate Batching System: Including aggregate silo, weighing device, conveyor belt and so on. Aggregate bins are used to store aggregates of different particle sizes, weighing devices measure the weight of aggregates accurately, and conveyor belts feed the weighed aggregates into the mixer.

-

Powder Batching System: It includes cement silo, fly ash silo, admixture silo, weighing device and conveying equipment. These equipments are used for storing and weighing cement, fly ash, additives and other powder materials.Water dosage system: including water tank, water pump, weighing device and so on. The pool stores water, the pump conveys the water to the weighing device and weighs it according to the recipe.

-

Mixing System: The mixer is the core equipment of the concrete mixing plant, which is used to mix all kinds of materials to form concrete. Common mixers are double horizontal shaft forced mixer, self-falling mixer and so on.

-

Control system: The control system is the nerve centre of the whole plant, which is responsible for controlling the operation of each equipment and ensuring the accuracy of concrete proportioning.

Working principle and process of concrete mixing plant

With the help of advanced automation control system, the concrete mixing plant can realise efficient and precise batching and mixing to ensure the stability of concrete quality.

Working Principle

Concrete mixing plants are usually divided into two types: fixed and mobile. Fixed mixing plants are usually larger in scale and suitable for large-scale, long-term and stable concrete supply, while mobile mixing plants are more flexible and suitable for small and medium-sized projects with frequent changes in construction sites.

Regardless of the type, the working principle of concrete mixing plant is similar. The entire production process relies on the following functions:

-

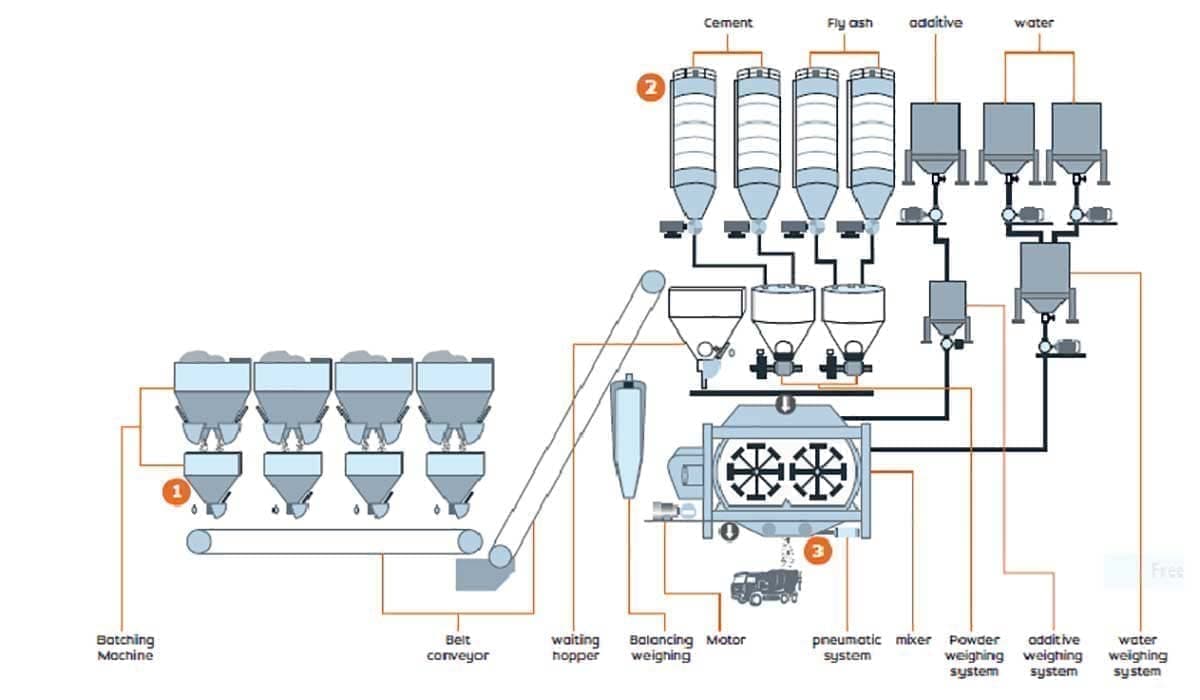

Aggregate supply: Aggregates and sand of different grain sizes are stored in separate silos.

-

Powder supply: This includes the storage and conveying of powdered materials such as cement, fly ash and mineral powder.

-

Water supply: Accurately measure and deliver the required amount of water according to the recipe.

-

Additives supply: Add various additives according to the requirements of concrete performance.

-

Mixing: Mix the weighed materials in the mixer to form uniform concrete.

-

Control system: Through the automatic control system, the whole mixing process can be precisely controlled.

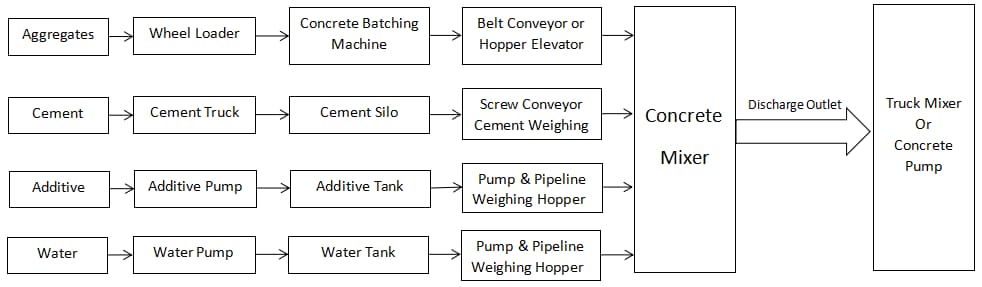

The whole process starts from the weighing of aggregates, through the batching, mixing, discharging and other links, and finally produce concrete that meets the requirements. Specifically, aggregate, powder, water and other materials are weighed according to the preset formula ratio.

Then they enter the mixer for mixing. After mixing, the concrete is sent to the construction site by conveyor belt or pumping equipment.

Concrete Batch Plant Workflow

In the workflow of the concrete mixing plant, the first stage is the batching stage. According to the project design requirements, the operator inputs the concrete formula into the control system, and the system will automatically control the weighing and conveying of aggregates, powders and water to ensure that the proportion of each batch of concrete is accurate.

Next is the mixing stage. The weighed materials are fed into the mixer, which fully mixes these materials by rotating at high speed to form a homogeneous concrete. The mixing time is adjusted according to the type of concrete and construction requirements to ensure the best mixing results.

Finally, there is the discharging stage. The finished concrete is conveyed to the transport vehicle or pumping equipment through the discharge port and subsequently transported to the construction site. This series of processes ensures the quality of concrete and construction efficiency, providing reliable material support for all types of construction projects.

Application of Concrete Batching Plant

Concrete mixing plant is widely used in construction projects, road and bridge, water conservancy projects and other fields. For example, in high-rise buildings, concrete mixing plants provide high-quality concrete for floor slabs, columns and other structures; in road and bridge projects, concrete produced by concrete mixing plants is used to pave roads and build piers.

Summary

Concrete mixing plants are able to produce high-quality ready-mixed concrete through precise formulas and efficient operating procedures, meeting the modern construction industry's demand for material quality and efficiency. With the development of technology, modern control systems make the production process more intelligent and automated, thus improving production efficiency and product consistency.

Frequently Asked FAQ about Concrete Batching Plant

How do you prepare different grades or qualities of concrete?

The grade and quality of concrete depends mainly on the proportion of its constituent materials, the mixing ratio, the mixing method and the curing conditions. By adjusting these factors, concrete can be produced to meet the needs of different projects.

Factors affecting the grade and quality of concrete

-

Cement varieties and dosage: Different varieties of cement have different properties, such as ordinary silicate cement, slag cement, volcanic ash cement, etc. The dosage of cement directly affects the strength of concrete. The amount of cement directly affects the strength of concrete.

-

Aggregate properties: Aggregate type, particle size, grading, water content, etc. will affect the performance of concrete.

-

Water-cement ratio: Water-cement ratio is one of the most important parameters in concrete mix ratio, which directly affects the strength and durability of concrete.

-

Admixtures: Admixtures can improve the performance of concrete, such as water reducing agent can improve the fluidity of concrete, early strength agent can accelerate the early strength growth of concrete.

-

Mixing time and method: Too short or too long mixing time will affect the uniformity of concrete, and the mixing method will also affect the quality of concrete.

-

Curing conditions: Curing conditions have a significant impact on the strength development of concrete. Factors such as temperature and humidity can affect the curing effect of concrete.

What are the common types of concrete batching plants?

There are two main types of concrete batching plants:

Dry mix concrete plants

A dry mix concrete plant dries all the components (such as aggregates, sand and cement) before feeding the materials into the transport mixer truck. All required materials are weighed and loaded into the transport mixer trucks and water is added during transport. On arrival at the construction site, the concrete is mixed in the transport mixer truck.

Wet mix concrete plant

A wet-mix concrete plant weighs each material individually, adds it to a mixing unit for uniform mixing, and then feeds the mixed material into a transport mixer truck or pumping plant. This type of mixing plant typically provides a more consistent product because all the ingredients are computer-assisted mixed in one central location, which ensures a homogeneous product.

Depending on the mobility of the mixing plant, it can be further categorised into the following two types:

Stationary Concrete Batching Plants

Stationary Concrete Batching Plants are generally larger in size, fixed at one location and are suitable for large-scale construction projects.

Mobile Concrete Batching Plant

Mobile concrete batching plant is smaller in size and can be moved to different construction sites, applicable to small and medium scale projects. Choosing the right type of batching plant can effectively meet the needs of different construction projects.

What are the main mixer types of concrete batching plant?

There are five main types of mixer units in concrete batching plant:

-

Reversible drum mixer: the drum of this type of mixer can rotate in both directions, with one side used for mixing and the other for discharging materials.

-

Twin-shaft mixers: driven by high-horsepower motors, they are capable of efficient mixing and are widely used in the European market.

-

Single Shaft Mixer: Similar to the Twin Shaft Mixer, but with only one mixing shaft, it is suitable for smaller scale concrete production.

-

Planetary Mixer: This mixer achieves uniform mixing of materials through planetary motion and is suitable for the production of precast elements.

-

Disc mixers: mainly used in precast applications, they are capable of efficiently mixing a wide range of components.

Each of these different types of mixers has its own characteristics and is capable of meeting different concrete production needs.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська