Small Concrete Mixing Plants for Sale Ukraine

In the rapidly developing construction market in Ukraine, there is an increasing demand for efficient and flexible equipment. small concrete mixing plants offer flexible and versatile solutions for all types of construction projects thanks to their economical and practical features. These compact mixing plants have become an important piece of equipment on construction sites, ensuring consistent quality and timely supply of concrete, especially against the backdrop of accelerated urbanisation.

When choosing the right compact concrete mixing plant, a number of factors need to be considered, such as capacity, mobility and level of technology. Manufacturers are also innovating with a wide range of options such as mobile and stationary to meet the individual needs of different projects. In addition, with the promotion of the concept of sustainable development, many new plants are designed to be more environmentally friendly and energy efficient.

This article will delve into the advantages of investing in a small concrete mixing plant in Ukraine, market trends, and key considerations when shopping for one to help you make an informed decision and move your construction business forward. According to market analyses, the Ukrainian construction industry is in a growth phase, and the government's focus on and investment in infrastructure development will further promote the development of this sector.

Ukraine Small Concrete Batching Plant Market In-depth Analysis

The demand for small concrete mixing plants in Ukraine has grown significantly over the past few years. This trend is mainly due to the rapid development of the construction market, which is in dire need of efficient and flexible tools to meet the requirements of diverse tasks. Small concrete batching plants stand out due to their cost-effectiveness, ease of installation and adaptability.

Introduction to small concrete mixing plants

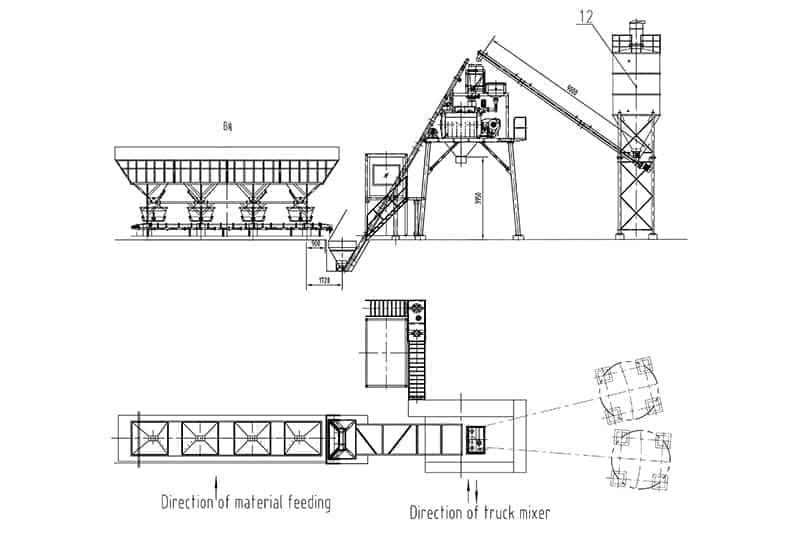

The Small Concrete Batching Plant is a well-designed plant that produces high-quality concrete quickly and reliably. Its compact structure makes it suitable for small and medium-sized construction projects with limited space. It usually includes core components such as concrete mixer, aggregate silo, cement silo and intelligent control system.

Why choose small concrete mixing plant?

-

Flexibility: Most models are designed to be compact, easy to transport and install, and highly adaptable to meet the needs of different sites.

-

Efficient production: Equipped with advanced control system to ensure even mixing and stable quality of concrete.

-

Economical: Lower investment cost and more economical operation cost than large-scale mixing plant.

Market situation and trends in Ukraine

The Ukrainian market for small concrete mixing plants presents the following characteristics:

-

Demand driven by infrastructure development: The construction of roads, bridges and other infrastructure projects is driving the demand for concrete.

-

Accelerated urbanisation: Accelerated urbanisation and high construction activities are driving the market for small-scale mixing plants.

-

Rise of green building concept: The pursuit of environmentally friendly materials and technologies in the construction industry has prompted mixing plant manufacturers to continuously introduce more energy-efficient and environmentally friendly products.

Small concrete batching plants have become an integral part of the construction industry in Ukraine. When considering a small concrete mixing plant, it is necessary to evaluate key specifications such as capacity, mixing time and power requirements. The table below highlights some of the common requirements for small concrete mixing plants:

| Parameter | Typical values | Description |

|---|---|---|

| Production capacity | 15-60 cubic metres/hour | Select the appropriate capacity according to the size of the project |

| Mixing time | 30-60 seconds | The shorter the mixing time, the higher the production efficiency |

| Power Requirement | 20-50 kW | Too much power increases operating costs; too little power affects productivity |

| Mobility | Mobile or stationary | Selected according to project requirements |

The selection of a small concrete batching plant should be evaluated based on specific job requirements, including the type of concrete needed and site conditions. By understanding market dynamics and technical requirements, buyers can make informed decisions that meet their operational goals.

Common types of small concrete batching plants

Based on different designs and features, small concrete batching plants can be categorised into the following types:

1. mobile small concrete batching plant

-

Characteristics: Mobile small concrete batching plant is easy to transport, install and dismantle, especially suitable for projects with small site or need to change the construction site frequently.

-

Advantage: it has strong flexibility and can adjust the position at any time according to the project demand.

-

Application Scenario: Widely used in road maintenance, bridge construction, small construction projects, etc.

Mobile concrete mixing plants are usually designed to be modular for quick assembly and disassembly. They can be put into use in a short time and are suitable for temporary or short-term projects.

2. Stationary small concrete batching plant

-

Characteristics: Stationary small concrete batching plant is usually installed at the construction site with relatively large production capacity.

-

Advantage: high production efficiency, suitable for long-term and large-scale concrete production.

-

Application Scenario: Commonly used in large-scale construction projects, prefabricated components production, etc.

Fixed mixing plants generally have higher production capacity and stability, and are suitable for projects that require a continuous supply of concrete.

Mobile vs Stationary Concrete Batching Plants

When considering the purchase of a small concrete batching plant in Ukraine, it is crucial to understand the differences between mobile and stationary batching plants. Each type has its own unique advantages, and your choice will significantly impact operational efficiency.

Mobility and Flexibility

Designed for flexibility and ease of transport, mobile concrete mixing plants are particularly suited to projects that require regular movement, such as road construction or work in remote areas. Its ability to be quickly set up and dismantled makes it ideal for projects that require frequent changes of location. In contrast, stationary batching plants are more suited to longer-term projects and are able to provide a continuous supply of concrete in one area.

Installation and set-up time

One of the major advantages of mobile mixing plants is their quick set-up time. Typically, they are pre-wired and pre-piped, reducing the time and effort required to get them up and running. This is in contrast to fixed mixing plants, which typically require more structural work and configuration processes. Therefore, if your project is time-critical, a mobile mixing plant may be a better option.

Production capacity

Stationary concrete batching plants typically have a greater capacity to handle larger volumes of concrete, making them suitable for high-demand tasks. While mobile batching plants offer portability, their production capacity may be relatively limited. It is important to assess the project's concrete needs before deciding which type to choose.

Cost Considerations

The initial investment in a mobile concrete batching plant may be higher because they are equipped with advanced mobile features. However, these costs can be offset by savings in transport and configuration time. While fixed mixing plants may be cheaper initially, they may incur additional site preparation and facility costs. When reviewing small concrete batching plants in Ukraine, it is not only the purchase price that should be considered, but also the long-term operating costs.

Maintenance and Durability

Both mobile and stationary batching plants require regular maintenance to ensure optimal performance. However, fixed mixing plants tend to have a longer service life as they are usually robust and have fewer moving parts. Frequently moving mixing plants may require more frequent inspections and maintenance to cope with wear and tear.

By taking a comprehensive look at both types of small concrete batching plants, you can make an informed choice based on your project's needs to improve construction efficiency and profitability.

Key Features to Consider When Buying a Concrete Batching Plant

When buying a small concrete mixing plant for sale in Ukraine, there are several key features to review to ensure that the mixing plant meets your functional needs and budgetary constraints. Understanding these features will help you make an informed choice that will benefit your building and construction project.

Capacity and output

The first characteristic to consider is the capacity of the concrete mixing plant. This describes the volume of concrete that the mixing plant can produce in a given period of time. It is vital to choose a mixing plant with a capacity that matches the needs of your task. A mixing plant that is too small could lead to delays, while one that is too large could lead to unnecessary costs.

Mobility

Another important consideration is whether the mixing plant is mobile or stationary. Mobile concrete batching plants have the advantage of being easy to move to different locations, which is ideal for tasks that are spread over multiple areas. On the other hand, stationary concrete batching plants are usually more robust and can handle larger volumes, making them suitable for long-term tasks in a single location.

Mixing technology

The mixing technology used in a mixing plant is also a key feature. Look for a mixing plant that offers an efficient mixing system, such as a twin-shaft concrete mixer, to ensure a consistent and quality concrete mix. The technology must also allow for the mixing of different types of concrete to meet multiple construction requirements.

Automation and control systems

Modern concrete mixing plants are often equipped with automation and control systems that improve efficiency and accuracy. These systems can handle the entire mixing process, from batch to mix to delivery, reducing the need for manual handling and minimising errors.

Durability and build quality

Durability is an important characteristic, especially considering the variable climatic conditions in Ukraine. A mixing plant should be made of quality materials that can withstand gradual wear and tear. Buying a durable mixing plant ensures longevity and reduces maintenance costs.

Environmental considerations

Finally, consider the environmental impact of the concrete mixing plant. Look for features that reduce dust and environmental pollution, and ensure that the mixing plant complies with local environmental regulations. Not only will this help protect the environment, but it will also improve working conditions on site.

By carefully reviewing these key attributes, you can choose a small concrete mixing plant that aligns with your operational goals and optimises your investment in Ukraine.

Top Manufacturers of Concrete Batching Plants in Ukraine

Ukraine has emerged as a major player in the construction industry with a growing demand for concrete mixing plants. This demand has led to the emergence of several top manufacturers specialising in small concrete mixing plants. Known for their cutting-edge designs, high-quality construction and reliable performance, these suppliers have become the recommended choice for many construction projects.

Top Manufacturers

Below are a few of the top concrete mixing plant manufacturers in Ukraine and their notable features and products:

| Manufacturers | Key Features |

|---|---|

| ZOOMJO | Offers mobile and stationary options, high efficiency, customised layouts, advanced control systems |

| UkrStroyMash | Smaller versions, energy efficient processes, robust construction |

| Elkon | Mobile and stationary options, quick set-up, durable performance |

| TekhnoMash | Innovative technology, cost-effective, easy maintenance |

Factors influencing manufacturer's choice

When choosing a manufacturer for a small concrete batching plant, several factors need to be considered to ensure ideal efficiency and cost-effectiveness:

-

Reputation: It is often safer to choose a manufacturer with a strong reputation for high quality and reliability.

-

Product range: Consider a manufacturer that offers a wide range of designs to suit a variety of tasks.

-

After-sales service: Reliable customer service and technical support can significantly enhance the user experience.

-

R&D capabilities: Manufacturers that invest in R&D to improve their products are able to offer more reliable and advanced solutions.

Choosing the best supplier of concrete mixing plants in Ukraine involves evaluating their product offerings, reputation and support services. By understanding the major brands in the market, users can make an informed choice that meets their specific needs and project goals.

Price trends of small concrete mixing plants in Ukraine

When considering the purchase of a small concrete mixing plant in Ukraine, it is crucial to understand the price trends. The cost of these mixing plants is significantly affected by a number of factors, including type, production capacity, and technical features. In recent years, price dynamics have changed significantly due to technological advancements, changes in market demand, and economic factors.

Factors affecting pricing

Here are a few key factors that influence the price of small concrete mixing plants in Ukraine:

-

Type of mixing plant: mobile mixing plants are usually more expensive than stationary concrete batching plants because they offer better transportability and easy setup.

-

Production capacity: higher production capacity batching plants usually cost more because they are capable of producing larger volumes of concrete.

-

Technical features: Plants equipped with advanced features such as automatic control systems and efficient mixers tend to be more expensive.

-

Brands and manufacturers: Well-known brands usually charge a premium due to their reputation and reliability.

Overview of current prices

The table below provides a basic overview of the current price range for small concrete mixing plants in Ukraine:

| Type | Capacity (cubic metres per hour) | Price range (USD) |

|---|---|---|

| Mobile | 10-30 | 8,000 - 20,000 |

| Fixed | 10-30 | 15,000 - 40,000 |

| Mobile | 30-60 | 28,000 - 100,000 |

| Fixed | 30-60 | 35,000 - 80,000 |

Budget Additional Costs

While the initial purchase cost is an important consideration, potential buyers should also budget for additional costs such as transport, installation and maintenance. These additional costs may vary depending on the location of the mixing plant and the complexity of the configuration process. In addition, regular maintenance can help extend the life of the mixing plant and ensure optimal performance, which ultimately provides better value.

How to choose the right capacity for your concrete mixing plant?

Checking the capacity of your mixing plant is one of the most crucial factors when considering buying a small concrete batching plant in Ukraine. The capacity of your concrete batching plant directly affects the efficiency and productivity of your construction project. Therefore, it is vital to choose the right capacity to meet your specific project needs and ensure optimal performance.

Understanding Batching Plant Capacity

The capacity of a mixing plant is usually measured in cubic metres per hour (m³/h), which indicates the amount of concrete that can be produced by the plant in a given period of time. For small concrete batching plants, capacity usually ranges from 15 m³/h to 60 m³/h. It is critical to assess your project needs to determine the ideal capacity.

Factors affecting capacity selection

There are several factors that influence your decision to select the right capacity for your concrete mixing plant:

-

Project size and scope: Consider the size and scope of your project. Larger projects that require large quantities of concrete will require a higher capacity plant, while smaller projects may be well served by a lower capacity plant.

-

Frequency of use: Evaluate how frequently the mixing plant will be in use. If you have ongoing or multiple projects, a higher capacity mixing plant may be more efficient and economical in the future.

-

Available space: The physical space available at the building site can also determine the capacity of the mixing plant. Make sure the footprint of the mixing plant fits the space you have available.

-

Budgetary constraints: Higher capacity mixing plants are usually more expensive. Find a balance between capacity needs and budget constraints to avoid overspending.

Matching capacity to project needs

To match the capacity of your mixing plant to your project needs, consider the following:

-

Peak demand: Identify the periods of peak demand in your project and ensure that the mixing plant can handle these peaks without causing delays.

-

Future Expansion: If you plan to expand the size or frequency of your project in the future, consider a slightly higher capacity mixing plant to accommodate future demand.

-

Performance and speed: A mixing plant with the right capacity will effectively manage your concrete needs, reducing wait times and increasing the speed of your project.

Choosing the optimal capacity for your small concrete batching plant is a critical decision that requires careful consideration of current and future project needs. By evaluating these factors, you can ensure that your investment in a concrete batching plant aligns with your operational goals and improves your construction efficiency.

Maintenance tips to extend the life of your concrete batching plant

Ensuring the longevity of your small concrete batching plant for sale in Ukraine requires regular and careful maintenance. Proper maintenance not only improves performance but also reduces the risk of unexpected breakdowns. Here, I share important maintenance tips to keep your mixing plant running efficiently.

Routine inspection and cleaning

Regular inspection and cleaning is crucial. Check for any signs of wear, especially on belts, bearings and blades. Clean the mixing drum regularly to prevent concrete build-up, which can lead to inefficiency and accelerated wear.

Lubrication of moving parts

Lubrication is essential to minimise friction and prevent overheating. Make sure all moving parts, such as mixing arms and bearings, are adequately lubricated. Use the manufacturer's recommended lubricant to maintain optimum performance.

Monitor and replace worn parts

Frequently monitor parts that are prone to wear, such as seals, gaskets and hydraulic systems. Replace any worn or damaged parts in a timely manner to avoid larger problems that could lead to costly repairs.

Electrical System Inspection

The electrical system is the heart of your concrete mixing plant. Regularly check electrical connections, wires and control panels for any signs of damage or rust. Make sure all safety equipment is working properly.

Calibration and Alignment

Accurate calibration and alignment of your mixing plant is critical to maintaining the quality of your concrete mix. Regularly adjust scales, sensors and meters to ensure accurate measurements. Imbalances can lead to uneven mixing and reduced mixing plant efficiency.

Documentation and Record Keeping

It is critical to keep detailed records of all maintenance work. Record inspections, repairs, and part replacements. This practice helps track the condition of the mixing plant and plan future maintenance schedules.

| Maintenance Activities | Frequency | Considerations |

|---|---|---|

| Inspection and cleaning | Weekly | Focus on drums and moving parts |

| Lubrication | Regularly every month | Use recommended lubricants |

| Parts Replacement | As needed | Inspection of wear-prone parts |

| Electrical inspection | Quarterly | Check connections and safety equipment |

| Calibration | Twice a year | Ensure accurate measurements |

By following these maintenance tips, you can significantly extend the life of your small concrete mixing plant and ensure it remains a reliable asset for your construction needs.

Where to Find Reliable Small Concrete Batching Plants in Ukraine

Finding reliable small concrete mixing plant in Ukraine requires careful consideration of several factors, including the supplier's reputation, product quality and after-sales service. I will guide you through the best resources and considerations for buying a concrete batching plant in Ukraine.

Reliable dealers and distributors

One of the most reliable ways to obtain a concrete batching plant is through certified dealers and distributors. These entities usually have proven track records and can offer guarantees of quality and service. When dealing with suppliers, it is vital to verify their credentials and customer reviews.

Online Marketplace

Online marketplaces have become a popular way to buy industrial equipment, including small concrete mixing plants. Sites such as Alibaba offer a wide selection from different manufacturers. Get in touch with professional concrete mixing plant manufacturers today.

Local Manufacturers

There are many local suppliers specialising in concrete mixing tools in Ukraine. Buying directly from a local manufacturer can often result in cost savings and better after-sales service. In addition, local manufacturers may offer customised options to meet specific project requirements.

Industry exhibitions and trade shows

Attending industry shows and exhibitions is an excellent way to explore the latest offerings in concrete mixing technology. These events provide opportunities to interact with manufacturers, see equipment demonstrations and discuss deals directly. Events also provide insight into emerging trends and technologies in the industry.

Comparative analysis of options

Before purchasing, it is advisable to conduct a comparative analysis of the different options available in the market. Consider factors such as price, capacity, warranty and customer support. The table below provides a comparative summary of key considerations:

| Considerations | Detailed Information |

|---|---|

| Price | Varies by manufacturer and model; typically ranges from $10,000 to $50,000 |

| Capacity | Options range from 10 cubic metres per hour to 50 cubic metres per hour. |

| Warranty | Standard warranty ranges from 1 to 3 years |

| Customer Support | Includes installation support, training and maintenance solutions |

In conclusion, buying a small concrete mixing plant in Ukraine requires careful analysis of suppliers, product features and market conditions. By utilising trusted suppliers, online platforms, local manufacturers and industry events, you can find a reliable mixing plant that meets your specific needs.

Frequently Asked Questions about Small Concrete Batching Plant in Ukraine

What are the main advantages of small concrete batching plant?

Small concrete batching plants offer a variety of advantages, including portability, cost-effectiveness and ease of installation. They are particularly suited to projects that require flexibility and mobility, with the ability to set up and relocate quickly.

How to determine the correct capacity of a concrete batching plant?

Choosing the right capacity depends on the size of the project, frequency of use and available space. Consider the peak demand for concrete as well as future expansion plans to ensure the mixing plant can efficiently meet your needs.

What factors affect the pricing of small concrete batching plants in Ukraine?

Pricing is affected by a number of factors, including the type of mixing plant (mobile vs. stationary), production capacity, technical features, and brand or manufacturer. Due to their mobility, mobile mixing plants are usually more expensive.

Why is concrete batching plant maintenance so important?

Regular maintenance is essential to extend the life of your mixing plant, improve performance and prevent unexpected breakdowns. Maintenance includes cleaning, lubrication, parts replacement and electrical system checks.

Where can I find a reliable small concrete mixing plant in Ukraine?

Reliable sources include authorised dealers, online marketplaces like Alibaba, local manufacturers, and industry exhibitions. It's important to verify a supplier's reputation and compare different options before making a purchase.

What is the difference between a mobile and stationary concrete batching plant?

Mobile batching plants offer flexibility and ease of transport, and are ideal for projects that require frequent relocation, while stationary batching plants are more suited to long-term projects, offer higher capacity and provide more robust performance.

What should I consider when choosing a concrete batching plant manufacturer?

When choosing a manufacturer, consider its reputation, product range, after-sales service and commitment to innovation. A strong reputation and reliable customer service are important factors in making an informed choice.

How do environmental factors affect the choice of a concrete batching plant?

When choosing a concrete mixing plant in Ukraine, you need to take environmental factors into account and choose the equipment that is suitable for the local climate, geographical conditions and environmental requirements.

What are the current market trends for small concrete mixing plant in Ukraine?

Demand for small concrete batching plants is on the rise with urban development and infrastructure projects. Manufacturers are offering competitive pricing and adding features to attract buyers to keep up with technological advancements and market demand.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська