What is the Difference Between Ready Mix Concrete and Batching Plant?

Concrete is an indispensable material in the construction industry, and its quality and construction efficiency directly affect the overall quality and progress of the project. Choosing the right concrete production method is crucial, and ready-mixed concrete and batching plant are two common concrete production methods, each with its own advantages and disadvantages. This article will discuss in detail the differences between ready-mixed concrete and batching plants, and analyze their application scenarios in construction projects to help construction professionals and project managers make informed choices.

Ready-mixed concrete: a guarantee of consistency and efficiency

Ready-mixed concrete is concrete that is pre-produced at a centralized plant in precise proportions, including raw materials such as cement, aggregates, water and additives. Mixing in a controlled environment ensures uniformity and consistent quality of the concrete. The ready-mixed concrete is then transported to the construction site via special trucks and is ready for immediate use, eliminating the need for on-site mixing.

Advantages

- Time-efficient: Eliminating the need for on-site mixing saves a lot of time and labor and improves construction efficiency.

- Consistent Quality: Controlled production environment and precise proportioning ensure consistent and reliable concrete quality.

- Reduced Waste: Strict material measurement and control reduces waste and improves cost-effectiveness.

Application Scenarios

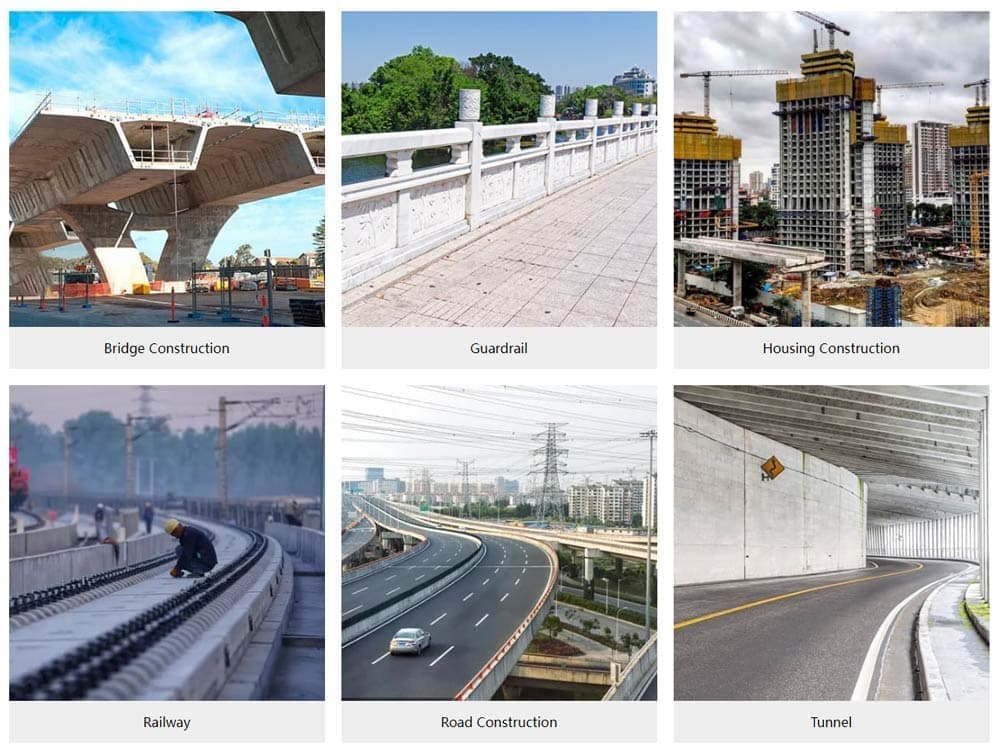

Ready-mixed concrete is ideal for large-scale construction projects, such as highways, bridges, skyscrapers, and water conservancy facilities, which often require large quantities of concrete with high demands on pouring speed and concrete quality.

Batching plants: flexible and customized concrete production solutions

A batching plant is a facility that can proportion, mix and prepare concrete components according to the needs of a specific project. It consists of aggregate silos, cement silos, water tanks, admixture tanks, conveying systems and control systems. A batching plant offers the flexibility to produce concrete directly at the construction site.

Advantages

- Customization: The concrete ratio can be flexibly adjusted according to the technical requirements and construction conditions of the project to meet the needs of different concrete types.

- Flexibility: The production process is controllable and the proportion can be adjusted in time according to the on-site situation to adapt to changes in construction.

- Cost control: On-site production can avoid the cost increase of long-distance transportation.

Application Scenarios

The batching plant is usually used in the following scenarios:

- Projects requiring special concrete ratios, such as lightweight concrete, high-strength concrete and durable concrete.

- Projects that require special concrete ratios, such as lightweight concrete, high-strength concrete, durable concrete, etc.

- Small batch, multi-size concrete construction projects.

Comparison between ready-mixed concrete and batching plant

| Feature | Ready-Mixed Concrete | Batch Plant |

|---|---|---|

| Production Environment | Central factory, controlled environment | Construction site |

| Transportation | Transported by dedicated trucks | Produced on site |

| Quality Control | Strict quality control system | Quality control depends on operators and equipment |

| Efficiency | High | Relatively lower |

| Cost | Affected by raw material prices and transportation distance | Affected by raw material prices and equipment investment |

| Applicable Scenarios | Large-scale projects with high demands for quality and speed | Special concrete needs, site limitations, small batch multi-grade projects |

Choose the right concrete production method for your project

Ready-mixed concrete and batching plants have their own advantages and disadvantages, and the choice depends on the specific project needs. For large-scale projects, ready-mixed concrete is a better choice because it offers higher efficiency, more consistent quality and lower costs. For projects that require special concrete ratios, site constraints or small batches with multiple grades, batching plants are more flexible.

Construction professionals and project managers should consider the project scale, concrete quality requirements, construction conditions, cost budget and other factors to choose the appropriate concrete production method to ensure the smooth progress and high quality completion of the project.

In addition, the following points need to be noted:

- Select a reputable ready-mixed concrete supplier or batching plant manufacturer.

- Strict quality control and testing procedures to ensure that the quality of concrete meets the construction requirements.

- Do a good job of technical training of construction personnel to improve the construction level.

- Through reasonable selection and scientific management, it can effectively improve the quality of concrete construction, reduce construction costs, and create greater value for the construction project.

ZOOMJO: Your Concrete Batching Plant Specialist

As a professional concrete batching plant manufacturer, ZOOMJO is committed to providing customers with high quality and high performance concrete production solutions. We have rich experience and advanced technology to meet your various concrete production needs.

A full range of products to meet your diverse needs

We offer a wide range of concrete mixing plants, including dry concrete mixing plants, wet concrete mixing plants, stationary mixing plants, mobile mixing plants and RMC batching plants, which can meet the construction needs of different sizes and types of projects.

High quality and performance to help your project succeed

Our concrete mixing plants are made of high quality materials, under strict quality control and testing, with stable and reliable performance, high productivity, low energy consumption, environmental protection and energy saving.

Perfect service system, so that you have no worries

We provide professional pre-sale, in-sale and after-sale service to help you choose the right concrete mixing plant, and provide installation, commissioning, training and other services to ensure the normal operation of your equipment. Contact us now for a free concrete batching plant consultation and quote!

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська