What is Dry Mortar Mix Plant?

With the rapid development of the construction industry, dry mortar is more and more favored by construction enterprises because of its advantages of light weight, convenient construction, energy saving and environmental protection. Dry mortar mixing plant as a professional production of various types of mortar important equipment, its performance level directly affects the quality of the final mortar products.

What is the process of dry mix mortar manufacturing?

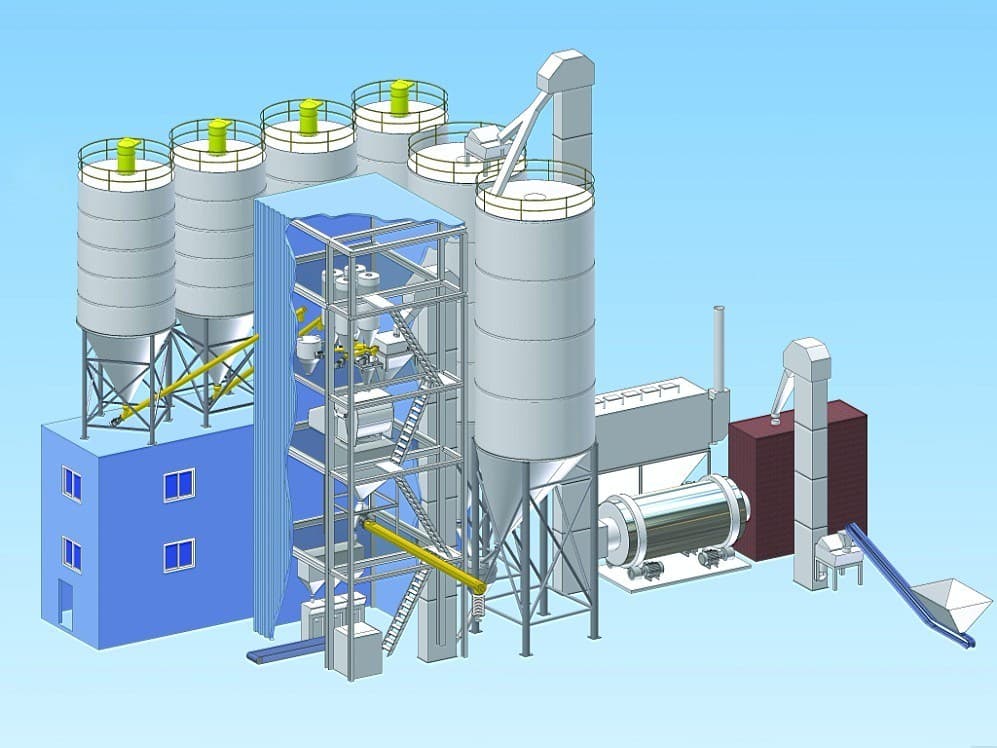

Dry mortar mixing plant consists of elevator, ready-mixing silo, cement silo, dry mortar mixer, finished product silo, packaging machine, dust collector, electric control cabinet and so on. It utilizes computer to accurately proportion all kinds of raw materials, which can be mixed by professional mixer at high speed to produce high-quality mortar products in accordance with the requirements of use. The fully automatic production control system ensures that the whole production process is fast, efficient and accurate.

According to the degree of automation and production capacity, dry mortar mixing plant can be divided into three categories: simple type, semi-automatic type and fully automatic type. Simple type with less investment is used for small output; semi-automatic type with strong expandability is suitable for medium investment; fully automatic type with high intelligence, large output and high efficiency is the ideal choice for large-scale building materials production enterprises.

The mixing system is the core component of the dry mortar batching plant. Single-axis pear leaf mixer mixes more evenly, suitable for professional special mortar; double-axis gravity mixer speed, low energy consumption, commonly used in ordinary mortar production. Reasonable selection of mixing system is very important to improve the output and product quality.

Dry mortar mixing plant price

The price of dry mortar mixing plant varies according to many factors, including the scale of production line, the type and brand of equipment, production capacity, technology level, and the location of the region, etc. Therefore, it is difficult to provide a specific price for dry mortar mixing plant. Therefore, it is difficult to provide a specific price.

Generally speaking, the price of a dry mortar batching plant may range from tens of thousands of dollars to millions of dollars. Small dry mortar production lines are relatively low in price and are suitable for startups or small-scale projects. Large, high capacity dry mortar production lines, on the other hand, can cost significantly more than smaller plants.

Before you consider buying a dry mortar mix plant, it is highly recommended that you contact us. We have a team of experienced and professional engineers and consultants who will provide you with up-to-date quotes and help you determine the type and size of equipment that best suits your project needs and budget. The final price will be based on your specific needs and selected equipment configuration.

Where can I buy the best dry mortar mixing equipment?

ZOOMJO is a leading supplier of dry mortar mixing equipment in China, offering a wide range of products from simple to fully automated models to meet the needs of different customers.ZOOMJO emphasizes on technological innovation, and the equipment adopts a modular design, which makes it flexible and easy to expand. ZOOMJO emphasizes on technological innovation, the equipment adopts modular design, flexible operation, easy expansion, precise dosage ratio control and efficient mixing system to ensure the quality of the product, combining efficiency and quality.ZOOMJO has exported its equipment to more than 100 countries around the world, and its products and services have been highly praised by the customers.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська