What is a Mobile Concrete Plant?

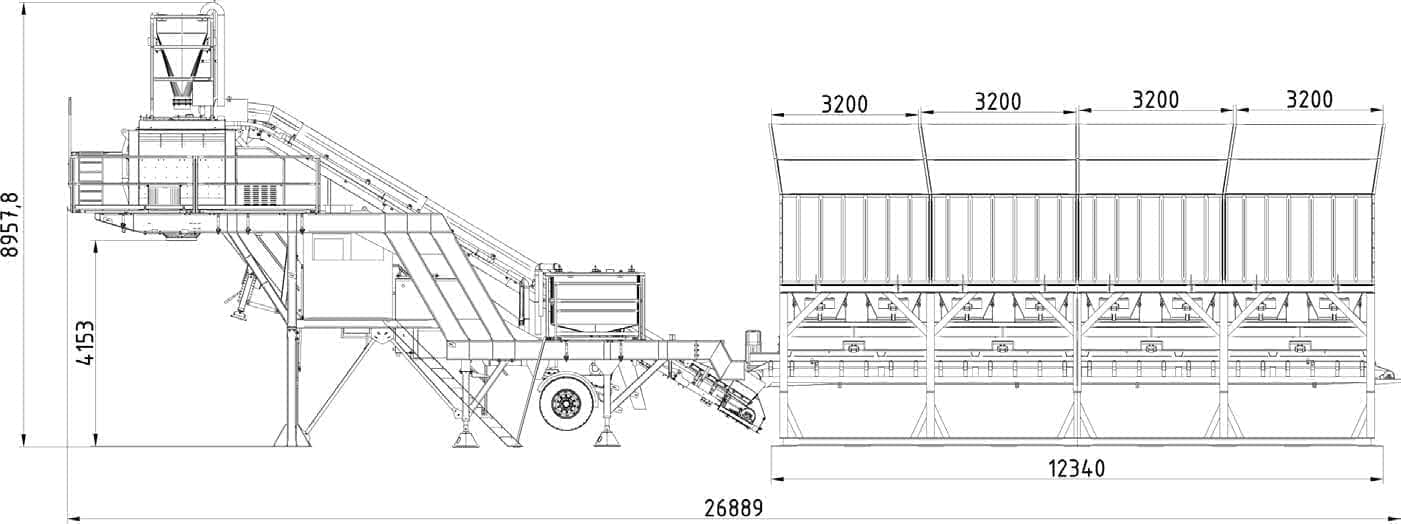

Mobile concrete mixing plant, also known as portable concrete mixing plant, is a kind of mobile concrete production equipment integrating aggregate conveying, cement metering, water and gray mixing, concrete discharging and other functions. It has the features of compact structure, flexible movement, easy operation and high production efficiency, and is widely used in construction, transportation, water conservancy, electric power and other engineering fields.

Composition of Mobile Concrete Batching Plant

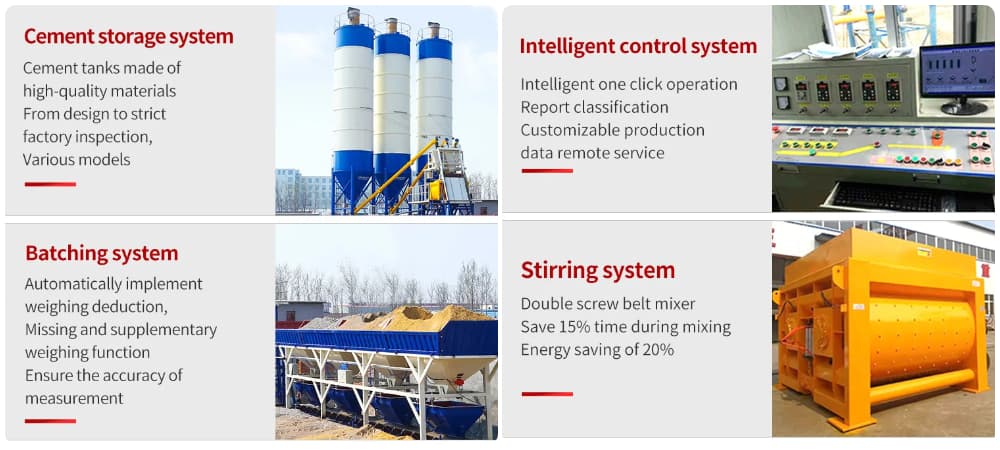

Mobile concrete mixing plant is a set of integrated concrete production equipment, and its core components include:

Mixer: as the heart of the plant, it is responsible for mixing various materials into concrete in proportion.

Aggregate feeding system: ensures the accuracy of the concrete mix ratio and accurately controls the amount of aggregates by means of conveyor belts and metering devices.

Cement Storage System: consists of cement silos, screw conveyors and dust collectors to keep the cement dry and clean.

Water and Additives Supply System: Controlling the amount of water and additives to optimize the performance of the concrete through precise metering devices.

Control system: as the "intelligent brain" of the plant, it realizes the automation and intelligent management of the production process.

How does Portable Concrete Batching Plant work?

The following is the working process of portable concrete mixing plant.

Feed Aggregate: Aggregate is sent to the metering device through conveyor belt or hopper, and then fed into the mixer after accurate measurement.

Add filler: cement, fly ash, etc. are sent to the metering device through screw conveyor or pneumatic conveying system, accurately measured and added to the twin-shaft mixer.

Feeding water and additives: according to the requirements of concrete performance, appropriate amount of water and additives are delivered to the mixer.

Mixing: The mixing system is activated and the mixing blades mix the materials into uniform concrete.

Transportation and Pouring: Finished concrete is delivered to the construction site by transfer pump or mixer truck.

Cleaning and Maintenance: Cleaning and maintenance is carried out after production to ensure that the equipment is in the best condition.

Mobile Concrete Batching Plant VS Stationary Concrete Batching Plant

| Feature | Mobile Concrete Batching Plant | Stationary Concrete Plant |

|---|---|---|

| Flexibility | High, quick to relocate and install, adaptable | Low, relatively fixed location |

| Equipment Structure | Compact, integrated, and easy to transfer | Large volume, multiple equipment combinations, requires fixed foundations |

| Production Capacity | Customized to meet the needs of different scales | Suitable for large-scale, continuous production |

| Installation and Dismantling | Simple and quick, time-saving and labor-saving | Relatively complex, time-consuming and labor-intensive |

| Applicable Scenarios | Remote and temporary locations for small to medium-sized projects | Large-scale, long-term, centralized production scenarios |

| Investment Cost | Low, suitable for small to medium investors | High, suitable for large or long-term operators |

Advantages of Mobile Concrete Batching Plants

High Flexibility: Quickly adapts to diverse and dynamic project environments, ensuring seamless project progress.

Automation and Intelligence: Increase productivity, reduce costs and ensure consistent concrete quality.

Easy installation and dismantling: shortens project preparation and delivery times, providing significant advantages for projects with stringent schedules.

Outstanding environmental performance: enclosed design reduces dust and noise emissions, and optional waste water recycling system realizes resource recycling.

Why do I need a mobile batching plant?

A mobile batching plant is capable of producing high quality concrete on site and meets EU safety industry standards. It is a portable unit that can be taken from one location to another as needed and make concrete to any specification. The benefits of using a mobile batching plant include eliminating construction costs and ensuring that projects receive durable, well-mixed concrete.

Functions of a mobile batching plant

A mobile batching plant is capable of producing many types of concrete, including flowable fill, quick-set concrete, cover concrete, pervious concrete, wet and dry spray concrete, self-compacting concrete, and crushed concrete. It is capable of producing concrete quickly, with installation on site completed within a day, after which you can rely on consistent, regular delivery of quality concrete.

Mobile Concrete Batching Plant Application Scenarios

Municipal works: to ensure seamless development of critical infrastructure such as roads and bridges.

Civil engineering: Providing a steady supply of concrete for commercial enterprises and residential areas.

Water conservancy and hydropower projects: demonstrating excellent performance in remote mountainous areas or river training.

Disaster relief: Rapid deployment to deliver much-needed concrete to disaster areas.

Environmental protection work: providing environmentally friendly concrete solutions for ecological restoration.

Medical works: accelerate the production of concrete foundations and isolation facilities for temporary field hospitals or emergency rescue centers.

Things to consider when choosing the right portable mixing plant

The following key aspects should be considered when choosing a portable concrete mixing plant:

Size and demand: meet the specific volume and production rate required for the project.

Mobility: Consider how quickly and easily the equipment can be transferred between locations.

Equipment quality: Choose high-performance and proven equipment.

Safety factor: Ensure that the equipment meets the relevant safety standards and has a comprehensive safety protection mechanism.

After-sales service: Evaluate the supplier's after-sales service policy and quality.

Economic benefits: Consider the purchase cost, operation cost, maintenance cost and long-term return on investment.

Sales and Rental of Mobile Concrete Batching Plant

Where can I buy mobile concrete mixing plant? ZOOMJO is a professional concrete equipment manufacturer and supplier, providing various models of mobile concrete mixing plant for sale and rental service. With years of industry experience and professional technical team, we can provide customers with high quality equipment and service.

If you are looking for mobile concrete mixing plant, please feel free to contact ZOOMJO.We will provide you with professional consultation and advice, and help you choose the most suitable equipment.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська