What is a Concrete Batching Plant?

Concrete batching plant, also known as batch plant or concrete mixing plant, is a kind of equipment that mixes various ingredients to form concrete. Concrete is an indispensable material in construction and consists of aggregates, cement, water and admixtures. A concrete batching plant precisely measures and mixes these components to produce concrete that meets specific strength and durability requirements.

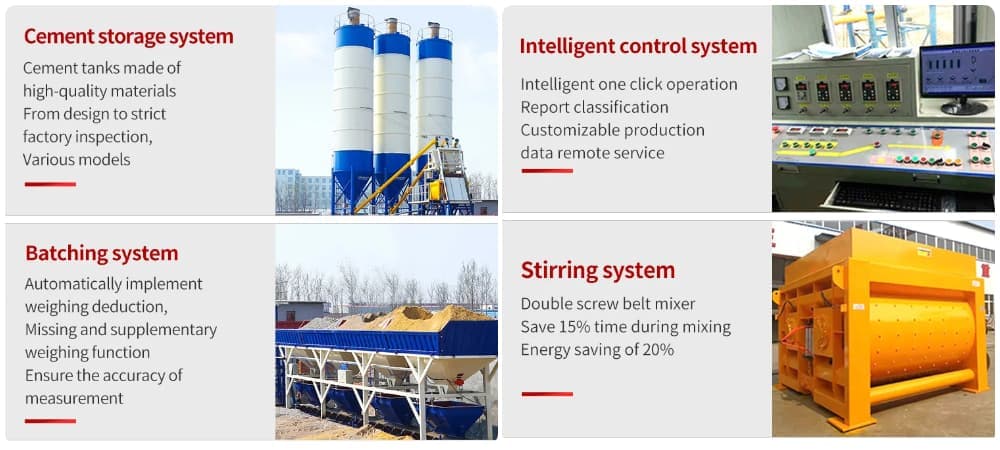

Components of a Concrete Batching Plant

A concrete batching plant consists of several key components, including:

Mixers: the core equipment of a mixing plant, common types include tilting drum, pan, planetary, single-shaft and twin-shaft mixers. Twin-shaft mixers are widely used in North America and Europe to ensure uniform mixing of concrete.

Aggregate bins: Used to store sand and aggregates of various sizes, usually with two to six bins.

Cement silos: for storing bulk cement, fly ash, mineral powder, etc. Types include bolted, horizontal and monolithic cement silos.

Conveyors: used to transport aggregates from ground level hoppers to aggregate bins, and from aggregate batchers to loading chutes.

Control systems: computer-aided controls are used to help measure and mix the various ingredients quickly and accurately, ensuring the quality of the concrete.

Types of Concrete Batching Plants

Depending on whether a central mixer is used or not, concrete batching plants can be categorized into dry batching plants and wet batching plants.

Dry batching plants: Aggregates, cement and admixtures are stored dry and mixed with water on site before being transported to the construction site.

Wet batching plants: aggregate, cement, water and admixtures are mixed in a central mixer and then transported to the site.

According to whether they can be moved or not, concrete batching plants can also be categorized into stationary concrete batching plants, mobile concrete batching plants, and foundationless concrete batching plants.

Stationary Concrete Batching Plant: usually used for large projects and permanently installed near the site.

Mobile Concrete Batching Plant: can be moved to different sites and is suitable for temporary projects or projects that require frequent movement.

Foundationless Concrete Batching Plant: can be installed and used without the need to build infrastructure. It adopts a steel frame and has the advantages of quick installation, flexible movement and cost saving.

Concrete Batching Plant Production Capacity

Concrete batching plants have a wide range of production capacities, from 25 to 240 cubic meters per hour. The difference in this range depends largely on the design size, model and configuration of the mixing plant. Large commercial concrete batching plants usually have a capacity of 120 cubic meters per hour or more, while small and medium-sized plants have a relatively lower capacity.

In addition to the construction scale of the site, factors such as the performance of the mixing host, the capacity of the storage depot, and the efficiency of the conveying equipment will also have an impact on the actual production capacity.

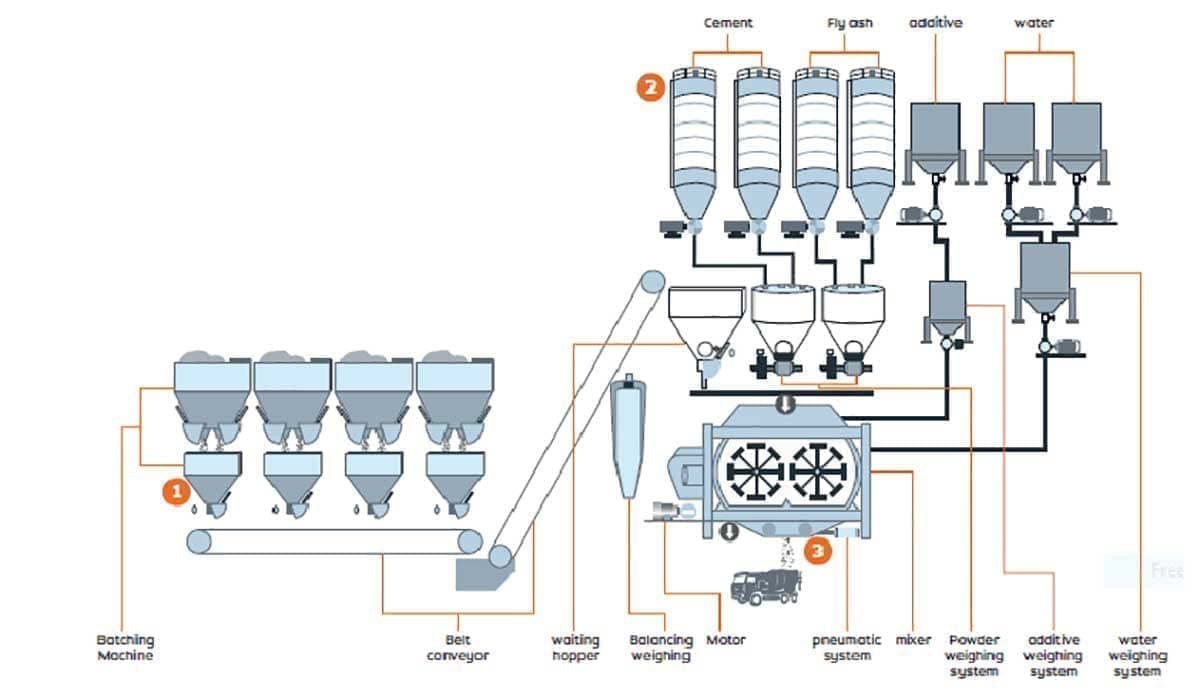

How does a concrete batching plant work?

A concrete batching plant produces concrete by accurately measuring and uniformly mixing aggregates, cement, water and admixtures.

The process begins with the measurement and delivery of aggregates: different aggregates such as gravel and sand are stored in separate silos and accurately measured by a weighing system before being delivered by conveyor to the hopper on top of the mixer.

Next, cement, water and admixtures are measured: cement is delivered to the measuring hopper via a screw conveyor, while water and admixtures are also measured and delivered to their respective hoppers. In the mixing process, the discharge door of the hopper is opened and all the materials are poured into the mixer and mixed evenly under the high speed rotation of the mixer.

Finally, the mixed concrete is discharged from the mixer's discharge port and can then be fed directly into the transportation mixer truck or concrete pump for delivery to the construction site.

Application of Concrete Batching Plant

Concrete batching plant is widely used in road construction, bridge construction, building construction, water conservancy projects, precast concrete production and other modern construction projects, for these projects to continue to supply high-quality commercial concrete, to meet the special needs of different projects on the concrete strength level, the use of the special performance, is to ensure the quality of construction projects and improve the efficiency of the construction of important facilities.

Advantages of concrete batching plant

- High degree of automation: through computerized control system, it ensures the accuracy of composition measurement and homogeneity of mixing.

- High production efficiency: capable of mass production of concrete to meet the demand of large-scale projects.

- Consistent quality: automated measurement and mixing process reduces human error and ensures consistent quality of each batch of concrete.

- Flexibility: the mobile batching plant can be flexibly relocated according to the project demand, adapting to different construction locations.

Selection of Concrete Batching Plant

The following factors should be considered when selecting a concrete batching plant:

- Production capacity: choose a mixing plant with suitable production capacity according to the material demand of the project.

- Concrete type: Select the appropriate concrete type of mixing plant according to the specific requirements of the project.

- Mobility: choose a fixed or mobile mixing plant according to the construction situation of the project.

- Price: choose the right mixing plant with the right price according to the budget.

Contact us today to learn about concrete batching plants

Are you looking for a top quality concrete batching plant for your road construction project?ZOOMJO can help!

ZOOMJO, as a leading construction equipment manufacturer, is committed to providing our customers with high performance, efficient, high quality and cost-effective concrete batching plant solutions. Our concrete batching plants are designed to meet the needs of all types of road construction projects and help you accomplish your goals efficiently.

Whether you have a small road construction project or a large infrastructure project, ZOOMJO can provide you with a customized concrete batching plant solution. Contact our team of experts today for a free consultation and quote!

Frequently Asked Questions (FAQ) about Concrete Batching Plant

How to check the quality of concrete batching plant?

Before using a concrete batching plant for the first time, please check the following points carefully:

- Vibrating screen: make sure the quality of steel, screen hole size and screening accuracy are in accordance with the standard.

- Transmission system: Check whether there is any abnormal noise and make sure it works smoothly.

- Conveyor and elevator: check for smooth operation and no jamming.

- Measuring system: check for flexibility and accuracy.

- Decelerator: check whether the temperature rise rate is in accordance with the regulations.

- Measuring hopper: check whether the material in and out is smooth, without accumulation and overflow phenomenon.

- Safety valve: check whether there is air leakage.

- Cement tank: check whether the quality is qualified.

- Circuit equipment: check whether it is reasonable and accurate.

What is the difference between concrete batching plants and traditional methods?

While conventional concrete batching methods involve manual measurement and mixing, a concrete batching plant is automated. It precisely measures and combines aggregates, cement, water and admixtures according to predefined ratios, ensuring consistency and accuracy in large-scale concrete production.

Can concrete batching plants meet customized ratios?

Yes, modern concrete batching plants can accommodate a variety of concrete ratio designs to suit different construction needs. Operators can input specific proportions of aggregate, cement, water and admixtures through the control system to produce customized concrete mixtures.

Can a batching plant be moved?

Yes, many concrete batching plants are designed to be mobile or semi-mobile for easy relocation to different construction sites. This is especially beneficial for construction companies working on projects at multiple locations. Mobile batching plants can be quickly transported to the site to be installed and put into operation, saving time and resources.

How do concrete batching plants ensure concrete quality?

Concrete batching plants ensure consistent quality by automating the measurement and mixing process. Advanced control systems closely monitor ingredient ratios, mixing times and other parameters to minimize human error and variation. This precision ensures that each batch of concrete meets the required strength, durability and other performance criteria.

What safety measures are in place at a mixing plant?

Concrete batching plants prioritize safety and have a variety of measures in place, including:

- Safety guards on moving parts

- Emergency stop buttons

- Ventilation systems to reduce dust and fumes

- Employee safety training

Compliance with occupational health and safety standards ensures a safe working environment for plant operators and personnel.

Can the batching plant be integrated with other equipment?

Yes, concrete mixing plants can be integrated with other construction equipment such as concrete pumps, mixers and conveyors to streamline the construction process. This integration allows for seamless transfer of freshly mixed concrete to the jobsite, increasing efficiency and reducing manual handling.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська