What are the Different Types of Batching Plants?

Batching plants, often referred to as concrete mixing plants, are used to mix raw materials such as aggregates, cement, water and additives into concrete. There are various types of batching plants, each designed for specific construction needs to suit different building projects.

Importance of Concrete Batching Plants

Concrete batching plants play a vital role in the construction industry, ensuring a steady supply of high quality concrete for a variety of projects. Whether it is for infrastructure development, housing developments, bridges or highways, concrete is an essential core building material. Batching plants ensure that the quality and performance of concrete meets the needs of all types of projects by accurately controlling the proportion of ingredients and automating the mixing process.

Common types of concrete batching plants

1. Stationary Concrete Batching Plants: These plants are usually installed at the project site and operate continuously throughout the project. They have the advantages of high production capacity, high mixing accuracy and stable operation, and are suitable for large-scale construction projects, such as bridges, dams and high-rise buildings.

2. Mobile Concrete Batching Plants: These plants are compact, easy to transport and install, and can be quickly moved to different locations according to construction needs. They are suitable for projects that require concrete to be used in multiple locations, such as road construction, small buildings, infrastructure rehabilitation, etc.

3. Compact Concrete Batching Plants: These plants have a small footprint and high space utilization, making them suitable for construction sites with limited space. They usually have a high degree of automation for efficient production.

4. Dry Mix Concrete Batching Plants: These plants pre-mix all raw materials except water and then add water to the mix during transportation or at the construction site. They have the advantages of high mixing precision and stable quality, and are suitable for projects with high requirements on concrete quality, such as prefabricated concrete components, decorative concrete, etc.

5. Wet Mix Concrete Mixing Plant: This type of mixing plant will mix all the raw materials (including water) in the mixing plant, and then loaded into the mixer trucks transported to the construction site. They have the advantages of high production efficiency and adaptability, and are suitable for all kinds of construction projects.

6. Centralized Concrete Mixing Plant: These plants mix all the raw materials in a centralized plant and then transport the finished concrete to the construction site. They have the advantages of large production scale, stable quality, good environmental performance, etc. They are suitable for large infrastructure projects, such as highways, airports, dams, etc.

7. Mobile Concrete Mixer: These mixer trucks install the mixing device on the truck, and can mix directly at the construction site. They have the advantages of high mobility, flexibility and convenience, and are suitable for small projects or special situations such as emergency rescue.

8. Continuous Concrete Mixing Plants: These plants can produce concrete continuously to meet the demand for high-strength and high-durability concrete. They are suitable for large infrastructure projects and special projects such as high-speed railroads.

9. Batch Concrete Batching Plants: These plants produce one batch of concrete at a time, and the concrete ratio can be adjusted according to the needs of different projects. They are suitable for projects that require high quality concrete, such as industrial buildings and military facilities.

10. Automatic Concrete Mixing Plant: This type of mixing plant adopts computer control system and can realize automatic production. They have the advantages of simple operation, high efficiency, stable quality, etc. and are suitable for modernized construction projects.

How to choose the right concrete mixing plant

When choosing a concrete mixing plant, you need to consider the following factors:

Project Size and Concrete Demand: Large projects require a mixing plant with a high production capacity, while smaller projects can choose a mixing plant with a lower production capacity.

Site conditions: Stationary plants require adequate installation space, while mobile plants are more flexible.

Concrete quality requirements: For projects with high concrete quality requirements, a high precision mixing plant is required.

Budget: There is a big price difference between different types of batching plants, so you need to choose according to your budget.

Choosing the right concrete mixing plant can improve the construction efficiency, reduce the cost and ensure the quality of concrete.

ZOOMJO Concrete Batching Plant For Sale - Reliable Quality and Global Service

ZOOMJO is a professional concrete batching plant manufacturer, we offer many types of concrete batching plants, including: stationary, mobile, compact, foundationless, continuous, dry and wet concrete batching plants, and our batching plant output ranges from 20m3 to 240m3. We are committed to providing our customers with high quality products, excellent pre-sales and after-sales services, and have several overseas offices around the world to provide you with services close to you.

Whether you are starting a new project or expanding an existing business, ZOOMJO has a concrete mixing plant solution to meet your needs. Contact us today to discuss your requirements and receive a free quote.

Frequently Asked Questions about Concrete Batching Plant

1、 What are the main parts of a batching plant?

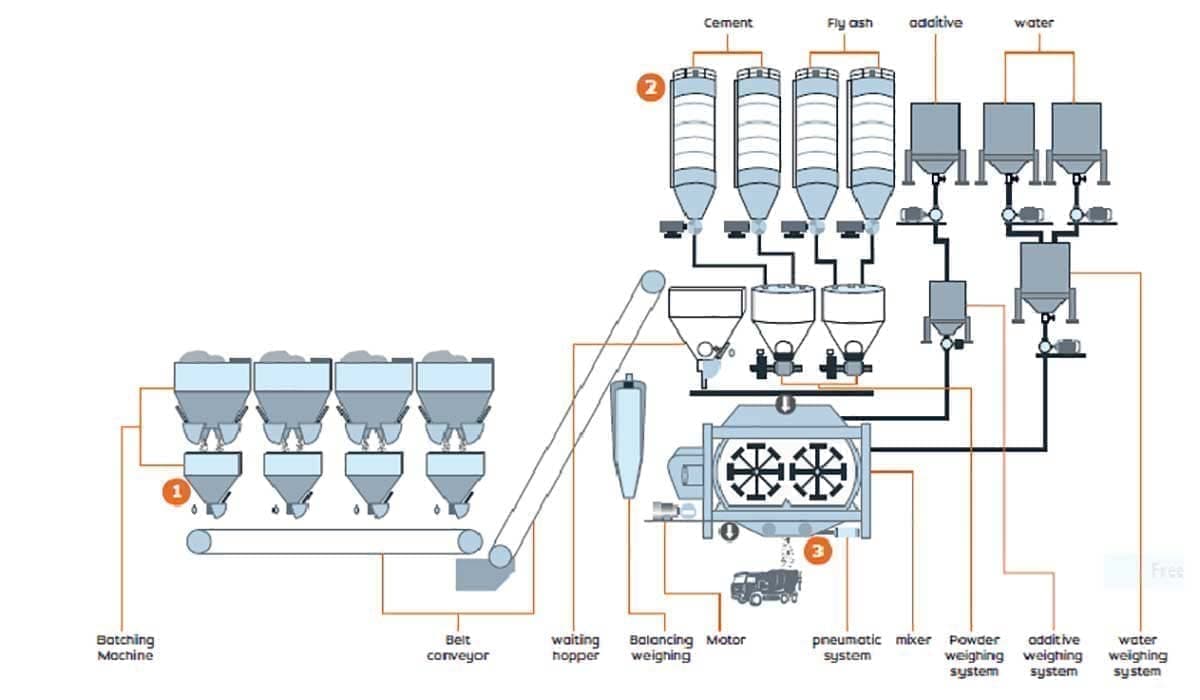

The main parts of the batching plant include aggregate silo, conveyor, cement silo, mixing device, control panel and so on.

3、 What is the capacity of concrete mixing plant?

The capacity of a concrete mixing plant varies greatly, from a small mixing plant with a capacity of about 25 cubic meters per hour to a large mixing plant that can produce hundreds of cubic meters per hour.

3. What are the factors to consider if choosing a used batching plant?

Factors to consider when choosing a used mixing plant include: condition, brand reputation, production capacity and maintenance history.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська