High Quality Dry Concrete Batching Plant Supply in Ukraine

In Ukraine, the supply of high quality dry concrete mixing plants is rapidly growing and becoming an integral part of the construction industry. With their advanced dry mixing technology, these plants not only achieve precise proportioning and homogeneous mixing of concrete, but also offer significant advantages in terms of water consumption, productivity and flexibility, which are more in line with the requirements of modern construction in terms of environmental friendliness and efficiency.

Dry Concrete Batching Plants: Efficient and Environmentally Friendly Concrete Production Solutions

Dry concrete mixing plant is a kind of equipment used to produce dry concrete, which is widely used in construction and infrastructure projects. Unlike traditional wet concrete mixing plants, dry concrete mixing plants do not add water during the mixing process; instead, all dry materials (e.g., cement, aggregates, and additives) are mixed together, and then water is added as needed when they are ready to be used.

Main Components

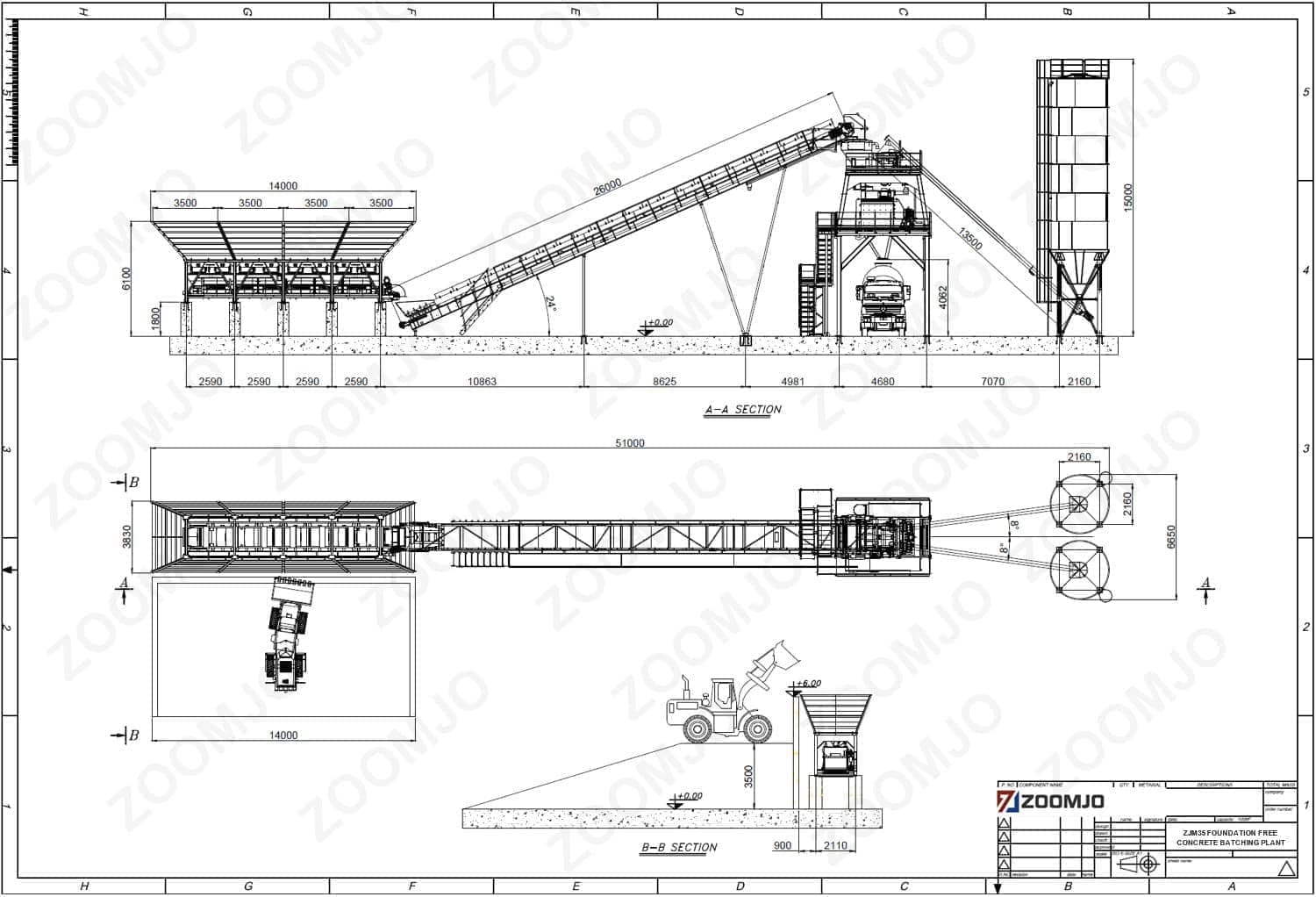

A dry concrete mixing plant usually consists of the following main components:

-

Silos: used to store cement, aggregates and other dry materials.

-

Mixer: responsible for mixing the dry materials well and ensuring the quality of the mixture.

-

Control System: Used to monitor and control the mixing process to ensure that the parameters are in accordance with the requirements.

-

Conveying system: conveys the mixed dry concrete to the construction site or storage area.

Core features of the dry concrete batching plant

Advanced mixing technology

High-quality mixing plants use state-of-the-art mixing systems to ensure uniformity of concrete. These systems are able to accommodate a wide range of concrete recipe designs, providing flexible solutions for a variety of construction projects.

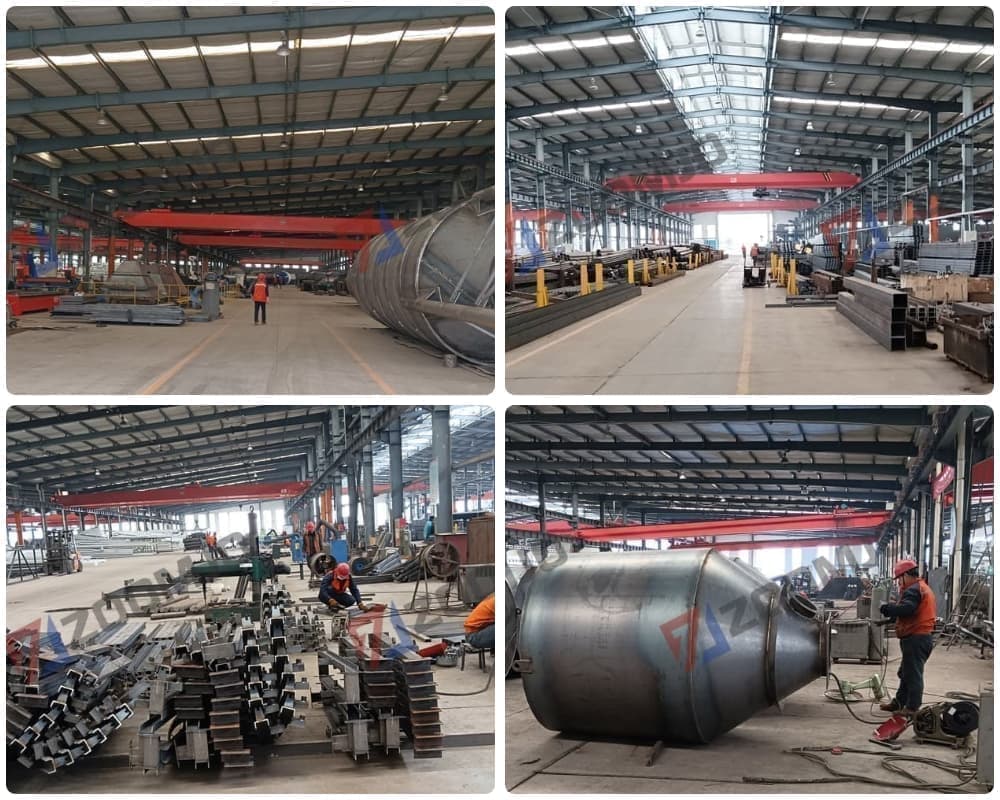

Robust and durable construction

The mixing plants are constructed with high quality materials to withstand harsh operating environments, ensuring long term reliability and reducing maintenance costs.

Efficient production capacity

Designed for high output, the mixing plant is able to meet the demands of large construction projects while maintaining high quality standards of concrete.

Precision and automation

Batching plants are equipped with automated control systems to accurately measure and mix raw materials. This precision ensures that the concrete product meets strict project specifications and fulfils the quality requirements of the building structure.

Environmentally Friendly Design

Modern mixing plants are environmentally conscious and equipped with features such as dust control, energy efficient design and noise reduction devices. These environmental measures are in line with the concept of sustainable development.

Easy maintenance

The modular design and easily accessible components make maintenance easier, reducing downtime and ensuring smooth operation.

Customisation options

Dry concrete mixing plants for sale in Ukraine can offer customised solutions for specific project needs, including adjustments to production capacity, integration of special technologies, etc., to meet the unique requirements of each project.

Areas of application

Dry concrete mixing plants are widely used in the following areas:

-

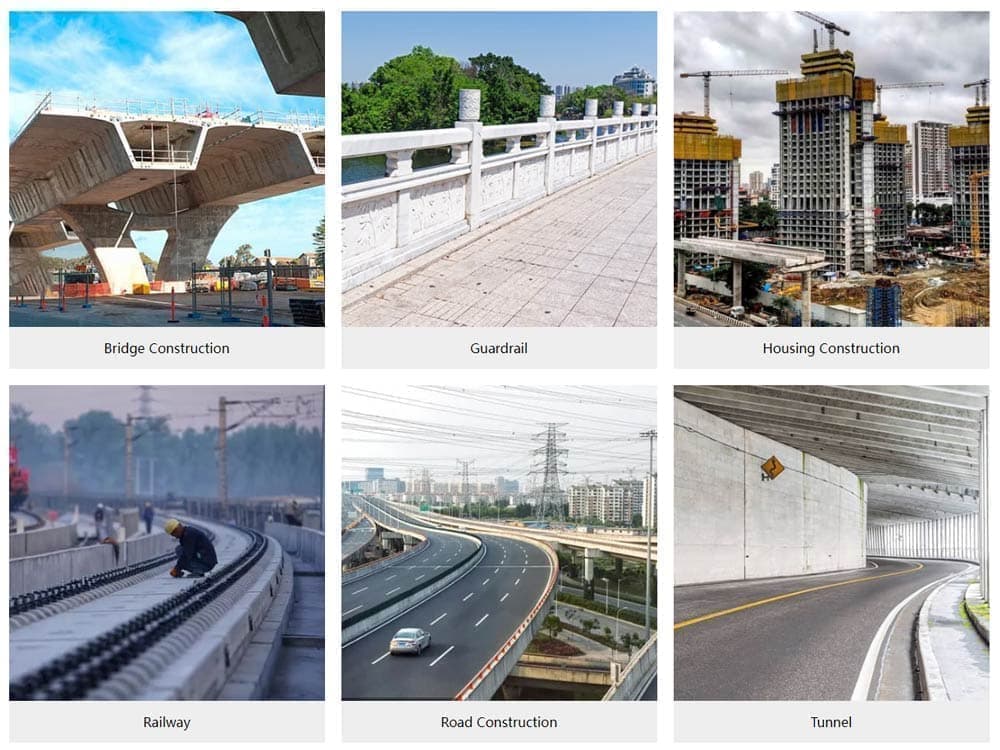

Construction: used to produce various types of concrete to meet the needs of different construction projects.

-

Infrastructure construction: such as roads, bridges and tunnels and other large-scale infrastructure projects.

-

Precast production: for the production of precast concrete components such as wall panels, beams and columns.

Difference between dry concrete mixing plant and wet concrete mixing plant

Dry and wet concrete mixing plant are two common types of concrete production equipment, they have significant differences in the working principle, scope of application and other aspects.

| Characteristics | Dry Concrete Batching Plant | Wet Concrete Batching Plant |

|---|---|---|

| Mixing Method | Dry material proportioning, on-site mixing with water | All materials are mixed in the mixer |

| Production efficiency | High, high degree of automation | Relatively low |

| Flexibility | High, flexibility to adjust ratios according to requirements | Relatively low |

| Environmental protection | Better, less water consumption, reduce the loss of materials in the transport process | Relatively poor |

| Scope of application | Large-scale projects, high-rise buildings, prefabricated components production, etc. | Small and medium-sized projects, on-site casting, etc. |

How to choose

Which type of concrete mixing plant to choose depends mainly on the following factors:

-

Scale of the project: It is recommended to choose dry mixing plant for large-scale projects, while wet mixing plant can be chosen for small-scale projects.

-

Concrete Quality Requirement: For projects with high concrete quality requirement, it is recommended to choose dry mixing plant.

-

Budget: The investment of dry mixing plant is higher, so it needs to be chosen according to the budget.

-

Site conditions: Consider the conditions of the construction site and choose the right equipment.

Dry and wet concrete mixing plants have their own advantages and disadvantages, and various factors need to be considered when choosing. Generally speaking, for large-scale projects and projects with high requirements on concrete quality, dry concrete mixing plant is a better choice; while for small and medium-sized projects and projects with relatively low requirements on concrete quality, wet concrete mixing plant is more suitable.

Benefits of investing in high quality dry concrete batching plant

Investing in a high-quality dry concrete batching plant in Ukraine brings numerous significant benefits to the construction industry. These plants not only increase the efficiency of concrete production, but also optimise the construction process in several ways.

Here are some of the main advantages of investing in a high-quality dry concrete batching plant:

1. Improving Durability and Consistency

High-quality dry concrete mixing plants produce concrete with superior durability and uniformity. This ensures that structures built with this concrete are stronger and require significantly less maintenance. Precise mixing techniques allow for consistency from batch to batch, reducing the risk of structural defects.

2. Increased efficiency and productivity

Utilising advanced technology, these mixing plants are able to produce large quantities of concrete in less time to meet tight construction schedules. Automation and precise operations reduce manual intervention, thereby reducing labour costs and time consumption.

3. Significant cost-effectiveness

Although the initial investment in a high quality dry concrete mixing plant is relatively high, the long term cost benefits are obvious. These plants save on material costs by reducing raw material wastage through accurate measurement and mixing. In addition, the reduced need for maintenance and repairs results in further savings in operating costs.

4. Environmental Advantages

Modern dry concrete mixing plants are designed with the environment in mind and often feature features to reduce dust and noise pollution. They also feature energy-efficient technologies that reduce the overall carbon footprint, making them more suitable for use in urban environments.

How to choose the right dry concrete batching plant for your project?

Choosing the right dry concrete batching plant for your project is an important decision that involves several factors. Here are some key steps and considerations to help you make an informed choice:

1. Determine project requirements

-

Production capacity: Determine the required production capacity (e.g., concrete output per hour ) based on the size of the project and concrete demand.

-

Concrete type: Consider the type of concrete you need to produce (e.g. normal concrete, special concrete, etc.) Different types of concrete may require different formulations and mixing methods.

2. Evaluate equipment specifications

-

Mixer type: Choose the type of mixer that suits your needs (e.g. forced mixer or self-falling mixer), different types of mixers differ in mixing uniformity and efficiency.

-

Silo capacity: Select the appropriate silo capacity according to the needs of the project to ensure sufficient raw material reserves.

3. Consider equipment quality and brand

-

Brand reputation: choose the equipment of famous brand, usually the quality and after-sales service are more guaranteed.

-

Material and workmanship: Pay attention to the manufacturing materials and workmanship of the equipment to ensure its durability and stability.

4. Technical support and after-sales service

-

Technical support: choose a supplier who can provide good technical support so that you can get timely help when you encounter problems during the use of the equipment.

-

After-sales service: Understand the supplier's after-sales service policy, including the warranty period, maintenance response time and so on.

5. Budget and financing programme

-

Cost control: under the premise of ensuring the quality of the equipment, consider the procurement cost, transport cost and installation cost of the equipment to ensure that it is within the budget.

-

Financing options: If the budget is limited, consider financing programmes or leasing options offered by the supplier.

6. Equipment flexibility and scalability

-

Flexibility: Choose equipment that has the flexibility to adjust mixing ratios and production capacity to different project needs.

-

Expandability: Consider possible future expansion needs and choose equipment that can be easily upgraded or expanded.

7. Site conditions and installation requirements

-

Site conditions: Evaluate the space and environmental conditions of the construction site to ensure that the selected equipment can be adapted to the actual situation on site.

-

Installation requirements: Understand the installation requirements of the equipment to ensure that the supplier can provide professional installation services.

By taking all these factors into consideration and making careful evaluations and comparisons, you can find the most suitable mixing plant for your project to ensure smooth progress and high-quality concrete production.

Recommended Manufacturers of Dry Concrete Batching Plants

Choosing a reliable dry concrete batching plant manufacturer is crucial for the success of your project. Here are some of the well-known dry concrete batching plant manufacturers in the Ukrainian market:

1. ConcreteMix Co.

Introduction: ConcreteMix Co. is a manufacturer specialising in concrete mixing equipment, offering a wide range of dry concrete mixing plant models for projects of different sizes.

Features: The equipment is efficient, durable and easy to operate for a variety of concrete production needs.

2. BuildTech Ukraine

Introduction: BuildTech Ukraine is a local Ukrainian concrete plant manufacturer offering a wide range of dry concrete mixing plant solutions.

Features: The company focuses on technological innovations and environmentally friendly design of its equipment to meet the needs of the modern construction industry.

3. MixMaster Group

Introduction: MixMaster Group is an internationally renowned manufacturer of concrete mixing equipment, offering high performance dry concrete mixing plants.

Features: Its equipment is known for its efficiency, flexibility and ease of maintenance, making it suitable for a wide range of construction and infrastructure projects.

4. Schwing Stetter

Introduction: Schwing Stetter is one of the world's leading manufacturers of concrete plants, offering a wide range of mixing plants, including dry concrete mixing plants.

Features: The company's equipment is known for its high quality and advanced technology for large-scale and demanding concrete production.

5. Ammann Group

Introduction: Ammann Group is a Swiss company specialising in the manufacture of construction and concrete equipment, offering a wide range of dry concrete mixing plants.

Features: Its equipment is characterised by high efficiency, environmental friendliness and intelligent design, suitable for the needs of the modern construction industry.

6. ELKON

Introduction: ELKON is a Turkish manufacturer of concrete mixing equipment, offering a wide range of dry concrete mixing plants, which are widely used in the global market.

Features: The company's equipment is known for its high performance and reliability, and is suitable for a wide range of concrete production needs.

7. ZOOMJO

Introduction: ZOOMJO is a company specialising in the manufacture of concrete equipment and is committed to providing customers with a wide range of high-quality products, including dry concrete batching plants, stationary concrete mixing plants, mobile concrete mixing plants, foundationless concrete mixing plants, concrete mixer pumps, concrete trailer pumps, and self-loading concrete mixers.

Features: its equipment is highly efficient, durable and intelligent, suitable for construction projects of various scales such as large, medium and small.

8. XCMG

Introduction: XCMG is a well-known construction machinery manufacturer in China, offering many types of concrete batching plants, covering both dry and wet batching plants.

Features: The company's equipment is known for its high cost performance and reliability, suitable for a variety of engineering needs.

This table below summarises the basic information and features of each manufacturer, making it easy for you to compare and choose.

| Manufacturer Name | Brief Introduction | Features |

|---|---|---|

| ConcreteMix Co. | A manufacturer specialising in concrete mixing equipment, offering a wide range of models of dry concrete mixing plants. | Efficient, durable, and easy to operate for a variety of concrete production needs. |

| BuildTech Ukraine | Local Ukrainian manufacturer of concrete equipment, offering a wide range of dry concrete batching plant solutions. | Focus on technological innovations and environmentally friendly design to meet the needs of the modern construction industry. |

| MixMaster Group | Internationally recognised manufacturer of high performance dry concrete mixing plants. | Efficient, flexible and easy to maintain, they are suitable for a wide range of construction and infrastructure projects. |

| Schwing Stetter | One of the world's leading manufacturers of concrete plants, offering a wide range of mixing plants. | High quality and advanced technology for large-scale and demanding concrete production. |

| Ammann Group | Swiss company specialising in the manufacture of construction and concrete equipment, offering a wide range of dry mixing plants. | Highly efficient, environmentally friendly and intelligently designed for the needs of the modern construction industry. |

| ELKON | Turkish manufacturer of concrete mixing equipment, offering a wide range of dry concrete mixing plants. | High performance and reliability, widely used in the global market. |

| SANY | A leading construction machinery manufacturer in China, offering a wide range of concrete mixing equipment. | Highly efficient, durable and intelligent, suitable for large-scale construction projects. |

| XCMG | China's leading construction machinery manufacturer, offering many types of concrete mixing plants. | Highly cost-effective and reliable, suitable for various engineering needs. |

Maintenance of dry concrete batching plant

In order to ensure the long-term stable operation of the dry concrete mixing plant, improve the production efficiency and ensure the quality of concrete, regular maintenance must be carried out.

Routine Maintenance

-

Cleaning: Regularly clean the cement, aggregate and other residues on the equipment to keep it clean.

-

Lubrication: Regularly lubricate the transmission parts, bearings, etc. according to the equipment manual.

-

Inspection: Check the various parts of the equipment, such as belts, chains, gears, etc., for looseness, wear and tear or damage.

-

Tighten: Regularly check and tighten the connecting parts of the equipment to prevent loosening.

Regular Maintenance

-

Check the electrical system: Check whether the electrical wiring and control components are intact to ensure the safe operation of the equipment.

-

Check the hydraulic system: check the level and cleanliness of the hydraulic oil, replace the hydraulic oil.

-

Check the weighing system: calibrate the weighing system regularly to ensure the accuracy of the dosage.

-

Check the mixing system: check the mixing blades for wear and tear and the mixing bearings for normalcy.

Seasonal Maintenance

-

Winter Maintenance: Strengthen the anti-freezing measures for the equipment, check and replace the anti-freezing liquid.

-

Summer maintenance: Enhance the heat dissipation measures for the equipment, check the cooling system.

Troubleshooting

-

Establishment of maintenance records: Establish detailed equipment maintenance records in order to find problems and solve them in time.

-

Develop contingency plans: Develop contingency plans in the event of equipment failure, so that rapid action can be taken in the event of failure.

Through scientific and reasonable maintenance, you can extend the service life of the equipment, improve production efficiency, ensure the quality of concrete, and provide a reliable guarantee for the construction of the project.

Frequently asked questions about dry concrete mixing plants for sale in Ukraine

What is the production capacity of a high quality dry concrete batching plant in cubic metres?

The production capacity of a dry concrete batching plant usually ranges from 20 cubic metres to 150 cubic metres per hour, depending on the model and configuration of the plant. Smaller batching plants may have a production capacity of 20-40 cubic metres per hour, while larger plants can reach 100 cubic metres per hour or more. Choosing the right production capacity should be determined by the size and needs of the project.

What is the market price range for a dry concrete mixing plant?

The market price range for a high-quality dry concrete batching plant in Ukraine is usually between $30,000 and $200,000 USD. The exact price is influenced by a number of factors, including the plant's production capacity, technical specifications, manufacturer's brand, and additional features.

How long does it take to install a dry concrete batching plant?

The installation time for a dry concrete batching plant usually depends on a number of factors, including the complexity of the equipment, its size, site preparation, and the experience of the installation team. In general, installation time can range from a few days to a few weeks.

How much does it cost to maintain a dry concrete batching plant?

Although the overall maintenance needs of a dry mixing plant are low, there are still some wearing parts that need to be replaced regularly, such as screens and conveyor belts, etc. The cost of these spare parts needs to be included in the maintenance costs.

Under what circumstances is it more appropriate to choose a dry concrete mixing plant?

Dry concrete mixing plants are suitable for infrastructure and road projects, especially when the construction site is far away from the mixing plant, to avoid premature setting of the concrete during transport.

What is the main difference between dry concrete mixing plant and wet mixing plant?

Dry concrete mixing plant keeps all the raw materials (sand, gravel, cement, etc.) dry before discharging and mixes them by adding water through the mixer truck during transport, while wet concrete mixing plant mixes water with other materials before discharging to form wet concrete.

What is the cost difference between dry concrete mixing plant and wet mixing plant?

The initial investment cost of a dry concrete batching plant is higher, but the operating and maintenance costs are lower than those of a wet batching plant.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська