Ukrainian Belt Stationary Concrete Batching Plant for Sale

In today's rapidly changing construction industry, the need for efficient and reliable concrete mixing equipment is becoming more and more urgent. Ukrainian Belt Fixed Concrete Batching Plants are a popular choice in the industry due to their outstanding performance, affordability and extremely low downtime. Designed to meet the high standards of modern construction, these stationary plants provide a consistent supply of high-quality concrete to ensure smooth progress.

Reviews of Ukrainian Belt-mounted Stationary Concrete Batching Plants

Ukrainian Belt-mounted Stationary Concrete Batching Plant is known for its high productivity, robust design and intelligent automated control system. Its energy-efficient mode of operation and excellent consistency in concrete proportioning make it an indispensable productivity tool for large-scale construction projects.

In this article, we will discuss the advantages of Ukrainian belt-type stationary concrete mixing plant, and combined with the actual application scenarios, we will provide you with the selection reference and maintenance advice to help you give full play to the potential of the equipment to achieve efficient production.

Ukrainian belt-type stationary concrete mixing plant has become the first choice in the construction industry for its advantages of high precision proportioning, high automation and high reliability. Compared with the traditional mixing plant, this equipment is characterised by high capacity, high stability and low maintenance cost.

Through modular design, the belt mixing plant can be flexibly configured according to customers' needs to meet projects of different scales. In addition, the equipment adopts advanced control system to ensure stable quality of concrete and comply with various engineering specifications.

Understanding Belt-type Stationary Concrete Batching Plant

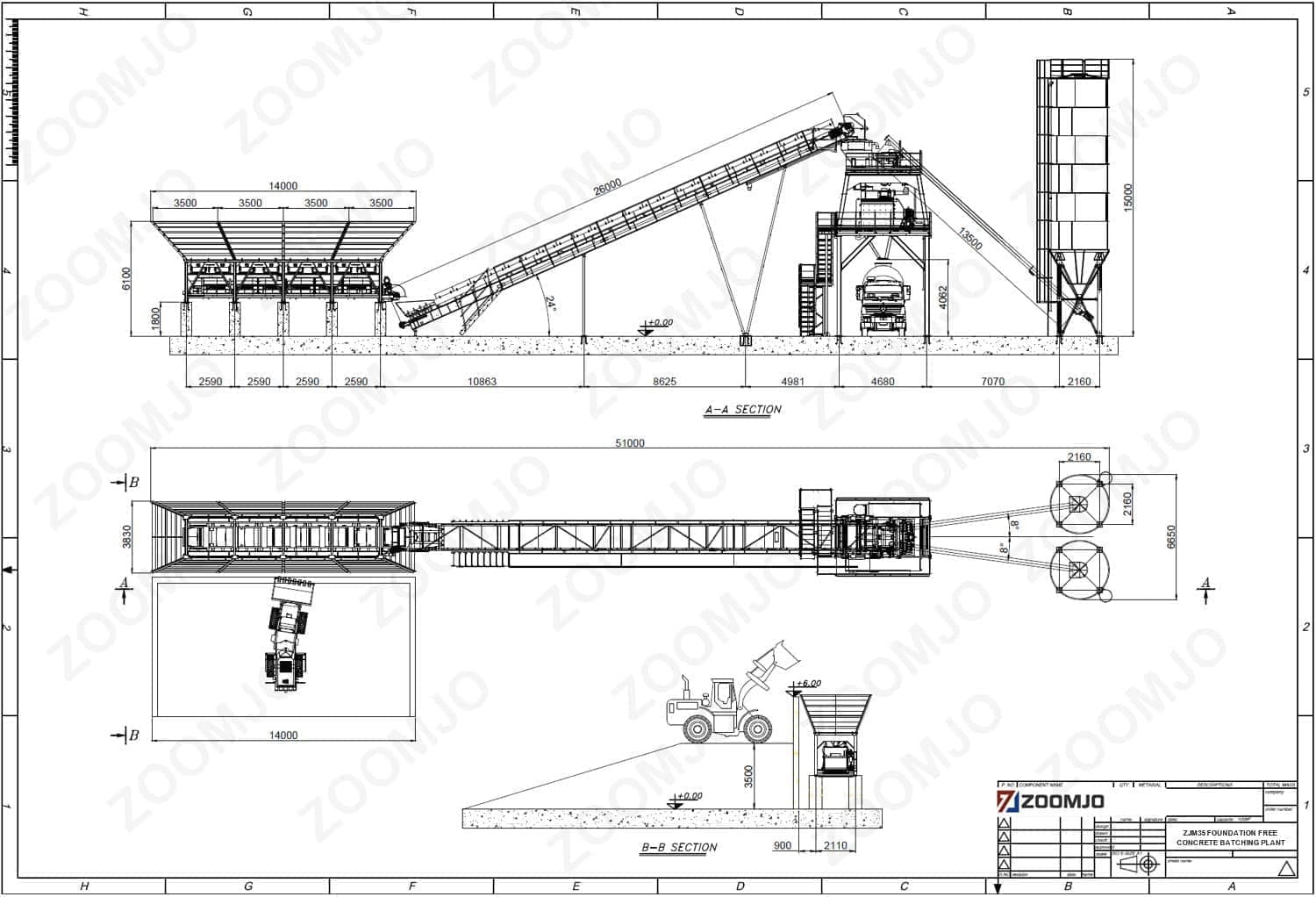

Belt-type stationary concrete mixing plant is a kind of efficient concrete production equipment. Various aggregates, cement and other raw materials are directly fed into the mixer through the conveyor belt, which realises a continuous and even concrete mixing process. Due to its stationary design, it is usually installed in a fixed position at the construction site, which is especially suitable for large-scale and long-term construction projects.

Characteristics of Ukrainian belt-type stationary concrete mixing plant

Ukrainian suppliers have developed a wide range of belt-mounted stationary concrete mixing plants, combining advanced technology with robust architectural design. Below are some of the key features:

| Features | Abstract |

|---|---|

| High capacity | Efficiently produces large quantities of concrete per hour, suitable for large projects. |

| Durable Material | Manufactured from high quality materials that can withstand harsh environmental conditions. |

| Automated control system | Equipped with a modern control system for precise mixing with minimal human intervention. |

| Reduced Costs | Designed to maximise energy use and reduce operating costs. |

High Capacity

With advanced belt conveyor technology and high speed mixing arms, the belt mixing plant achieves continuous and stable delivery of aggregates and efficient mixing of concrete. Its excellent production efficiency makes it an ideal choice for the rapid supply of concrete for large-scale projects. By shortening the concrete production cycle, it effectively accelerates the construction progress and improves the overall efficiency of the project.

Durable Material

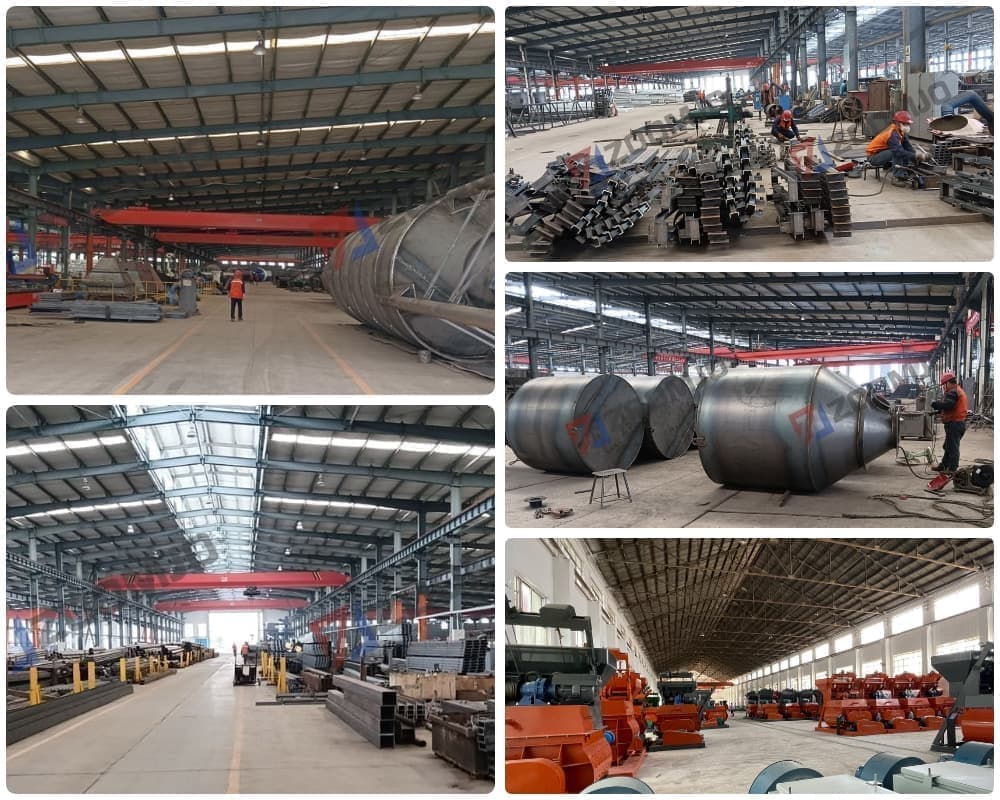

The main body of the mixing plant adopts high-strength steel structure, which is corrosion-resistant and wear-resistant, and can operate stably for a long period of time even under the harsh construction environment. The key components are selected from international famous brands to ensure the reliability of the equipment.

Automatic control system

The modern automated control system makes the concrete proportioning and mixing process more accurate and reduces manual intervention. This not only improves production efficiency, but also reduces quality problems caused by human error, thus ensuring the consistency and reliability of the concrete.

Reduced Costs

By optimising the production process, energy consumption is reduced and production costs are lowered. At the same time, the equipment has a low failure rate and low maintenance costs, which saves a lot of money for your project.

Application of Belt Mixing Plant

Due to its high efficiency and reliability, Ukrainian Belt Type Fixed Concrete Batching Plant is widely used in all kinds of projects, including large-scale infrastructure construction such as highways, bridges and tunnels, commercial buildings such as high-rise buildings and shopping malls, as well as industrial plants such as industrial parks and logistic centres, and even water conservancy projects such as dams and reservoirs.

All in all, Ukrainian belt-mounted stationary concrete mixing plants offer a reliable and trustworthy solution for large-scale concrete production. Their robust design and advanced features make them an indispensable asset in construction projects that seek quality and sustainability.

How to choose the right concrete mixing plant for your needs?

Choosing the right concrete batching plant is a critical step in ensuring the success of your project. Here are some practical tips to help you make an informed choice based on your specific needs.

Understand your project requirements

Before choosing a concrete batching plant, it is important to first identify the specific needs of your project. Consider the following aspects:

-

Scope of operation: what locations do you plan to work in?

-

Type of concrete: What type of concrete do you need to produce?

-

Frequency of projects: Are your projects one-off or long-term?

-

Belt Concrete Batching Plants are particularly suitable for projects that require large quantities of continuous high quality concrete.

Checking production capacity

Production capacity is an important factor when choosing a mixing plant. You need to determine the amount of concrete required per hour or per day. Belt-mounted stationary mixing plants are known for their high performance and are able to meet the demands of large-scale production, making them ideal for tasks that require high throughput.

Consider mixing plant mobility and installation

When choosing a mixing plant, consider whether you need a stationary or mobile concrete batching plant. Belt-mounted concrete batching plants are usually fixed and installed, offering greater safety and efficiency. If your project is long-term and located in a fixed location, a stationary mixing plant may be the best option.

Quality and Durability

Purchasing a high-quality mixing plant will ensure its longevity and structural integrity. Look for a mixing plant that is made of sturdy materials and has a good reputation in the industry. Ukrainian manufacturers typically offer durable and reliable equipment.

Technology and automation

Modern concrete mixing plants are often equipped with advanced technology and automation features that improve production accuracy and reduce labour costs. When making your selection, evaluate the technical features of your mixing plant to ensure that they match your operational goals.

Cost Considerations

While budget is always an important factor, the choice should be balanced between cost and the value provided. Affordable solutions should not come at the expense of quality or performance. Consider the long-term value and potential return on investment when making your decision.

Manufacturer Reputation and Support

It is vital to choose a manufacturer with a reputation for quality and customer support. Reliable after-sales service, spare parts supply and technical support are essential to ensure smooth operations. Research customer reviews and feedback to assess the supplier's reputation and service quality.

By taking these aspects into consideration, you can more effectively select the concrete mixing plant that best suits your project's needs, thus laying the foundation for a smooth running project.

Ukrainian belt mixing plant brand, model full analysis

In Ukraine, there are several popular models of belt-mounted stationary concrete mixing plants available in the market, which are mainly manufactured by well-known brands. These models are widely popular for their efficiency, durability and adaptability to different project requirements. Some of the popular brands and their models available in the Ukrainian market are described below.

ZOOMJO GROUP

ZOOMJO GROUP is a manufacturer specialising in concrete mixing plants and is known for its efficient and reliable products. The company is committed to technological innovation and offers a wide range of concrete mixing plants to meet the needs of different customers.

-

Model: ZJ Series

-

Features: Equipped with JS series twin-shaft forced mixer, it can mix the concrete quickly and evenly to ensure the quality and consistency of concrete.

-

Scope of application: suitable for large-scale construction projects, especially when high productivity and stable supply are required.

ELKON

ELKON is a leading global manufacturer of concrete mixing plants with nearly 50 years of industry experience. Known for its high quality and advanced technology, the company offers a wide range of stationary and mobile concrete mixing plants.

-

Model: ELKOMIX-135

-

Features: Known for its high productivity and automation, it is able to significantly improve work efficiency.

-

Scope of application: Suitable for demanding infrastructure projects such as motorway and bridge construction.

Liebherr

Liebherr is a globally recognised manufacturer of construction equipment, renowned for its innovative design and outstanding performance. The company offers a wide range of concrete mixing plants that are widely used in all types of construction projects.

-

Model: Betomix 3.0

-

Features: With sturdy construction and powerful handling capacity, it is suitable for large-scale projects.

-

Scope of application: Widely used in construction projects that require high strength concrete.

UkrStroy

UkrStroy is a local manufacturer specialising in affordable and efficient concrete mixing solutions for the Ukrainian market. The company is committed to developing customised products according to market needs.

-

Model: MixMaster-30

-

Features: Combining economy and performance, it is particularly suitable for small and medium-sized construction tasks.

-

Scope of application: Ideal for projects with limited budgets that still require reliable performance.

Betonmash

Betonmash is a local Ukrainian company recognised for providing high quality and durable concrete mixing equipment. The company's product line encompasses a wide range of mixing plants to meet different customer needs.

-

Model: BM-60

-

Features: Good balance between effectiveness and speed to meet various construction needs.

-

Scope of application: Suitable for many types of construction projects, including residential and commercial projects.

| Brand | Model | Features | Scope of application |

|---|---|---|---|

| ZOOMJO | ZJ Series | Equipped with JS series twin-shaft forced mixer, fast and uniform concrete mixing. | Large-scale construction projects with high capacity requirements |

| ELKON | ELKOMIX-135 | High capacity, high automation, increased efficiency | Infrastructure projects such as motorway and bridge construction |

| Liebherr | Betomix 3.0 | Robust construction, powerful handling | Large-scale projects, where high strength concrete is required |

| UkrStroy | MixMaster-30 | Economy and performance for small and medium-sized construction tasks | Projects with limited budgets but requiring reliable performance |

| Betonmash | BM-60 | Effectiveness and speed balanced for a wide range of construction needs | Residential and commercial projects |

Contact concrete mixing plant manufacturers today for the latest mixing plant quotes!

Maintenance Tips for Belt Fixed Concrete Batching Plants

Proper maintenance is critical to the durability and reliable operation of a belt-mounted stationary concrete mixing plant. Regular maintenance not only extends the life of your equipment, it also reduces downtime and lowers repair costs. Here are some comprehensive maintenance tips to help you keep your mixing plant in tip-top shape.

1. Routine inspection and cleaning

It is vital that all parts of your mixing plant are inspected regularly, especially the conveyor belt, which is a key component of the equipment. Please note the following:

-

Signs of wear: check for cracks, abrasion or imbalance.

-

Cleaning: Clean the equipment regularly to remove concrete residue and prevent performance from being affected.

2. Lubrication of moving parts

Ensure that all moving parts (such as bearings and gears) are adequately lubricated to minimise friction and prevent excessive wear.

3. Belt tension and alignment

Maintaining proper belt tension and alignment is critical to the smooth operation of your equipment:

-

Tension: A belt that is too loose may slip, while a belt that is too tight may cause excessive wear.

-

Alignment: Regularly check and adjust belt tension to ensure it is properly aligned to prevent it from going off track and causing operational problems.

4. Electrical System Inspection

Periodically check the electrical system to ensure there are no signs of damage or wear:

-

Connections: make sure all connections are secure and there are no exposed wires.

-

Function check: test electrical components regularly and replace any defective components promptly.

5. Replacement of worn parts

Over time, certain components will wear out and need to be replaced:

-

RECORD LIFE: Keep a record of the life of each component and replace as needed to avoid unexpected failures.

-

High Quality Parts: Always use high quality and compatible parts to maintain the integrity of your equipment.

6. Documentation and record keeping

Detailed records are kept of all maintenance tasks, including inspections, repairs, and part replacements. These records help to identify wear patterns and provide a reference for solving future problems.

| Maintenance Tasks | Regularity |

|---|---|

| Inspection and cleaning | Weekly |

| Lubrication | Monthly |

| Belt tension and alignment | Fortnightly |

| Electrical system check | Quarterly |

| Replacement of wear parts | As needed |

By following these maintenance recommendations, you can ensure that your Ukrainian Belt Fixed Concrete Batching Plant operates efficiently and accurately, helping you achieve optimal production results.

Frequently Asked Questions about Ukrainian Belt Fixed Concrete Batching Plant

Q:What is the demand for belt fixed concrete batching plant in Ukraine market?

A: With the rapid development of infrastructure in Ukraine, the market demand for belt-type stationary concrete mixing plants continues to grow. This trend is further fuelled by supportive government policies and economic investments.

Q: What is a belt-type stationary concrete mixing plant?

A: A Belt Fixed Concrete Batching Plant is a machine that uses a conveyor belt system to feed raw materials directly into the mixing chamber and is suitable for large construction projects to provide continuous and uniform concrete production.

Q: What is the difference between a belt-mounted stationary concrete mixing plant and a mobile mixing plant?

A: Belt-mounted stationary concrete mixing plant is usually installed in a specific location, which is suitable for long-term and large-scale projects with higher productivity and capacity. The mobile batching plant can be moved at any time according to the need, which is suitable for small and medium-sized projects and changing construction environment.

Q:What are the common mixing plant capacities in the Ukrainian market?

A: The Ukrainian construction market has seen an increase in demand in recent years, with common capacities ranging from 25-50 m³/h for small-scale projects, 75-120 m³/h for medium-sized projects, and 150-200 m³/h for large-scale projects.When choosing a capacity, it is important to take into account the size of the project, the amount of concrete demanded, and the production cycle.

Q:What is the price of Ukrainian belt fixed concrete mixing plant?

A: The price of the equipment will vary according to the configuration, capacity and other factors. It is recommended that you contact the specific supplier for a quote.

Q: What factors should be considered when choosing a belt fixed concrete mixing plant?

A: The following should be considered when selecting:

-

Production capacity: Ensure that the plant meets the concrete needs of the project.

-

Budget: Evaluate the initial investment and operating costs, including maintenance and labour.

-

Space Requirements: Ensure there is enough space to install and operate the equipment.

-

Environmental regulations: Follow local environmental regulations and select equipment that reduces pollution.

Q: How do I maintain my belt-mounted stationary concrete mixing plant?

A: Effective maintenance includes:

-

Regular inspections: check the electrical, mixing and feeding systems regularly to identify and solve problems in time.

-

Keep clean: Keep the equipment and surroundings clean, especially inside the mixer.

-

Lubrication: Regularly lubricate the rotating parts and bearings to ensure the smooth operation of the equipment.

-

Anti-freezing measures: Take measures to prevent water pipes and water tanks from freezing in cold areas.

-

Spare parts management: Prepare common wear and tear spare parts for quick replacement to reduce downtime.

Q: What are the main components of a belt-mounted stationary concrete mixing plant?

A: The main components include:

-

Mixing system: responsible for mixing the raw materials.

-

Storage system: for storing raw materials such as aggregate and cement.

-

Conveying system: conveys the materials from the storage area to the mixer.

-

Weighing system: ensures that all raw materials are weighed proportionally.

-

Control system: realises automated control and improves operational efficiency.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська