Top10 Ready Mix Concrete Batching Plant Manufacturers

With the booming development of global infrastructure, ready-mixed concrete mixing plants are playing an increasingly important role in the construction industry. This article will introduce the world's top ten manufacturers of commercial mixers, which provide a variety of efficient and practical concrete mixing equipment for the construction machinery market around the world, which can be used to produce concrete products in batches at any location. Even in harsh construction sites, operators can manage and execute the entire work process through human-machine interface.

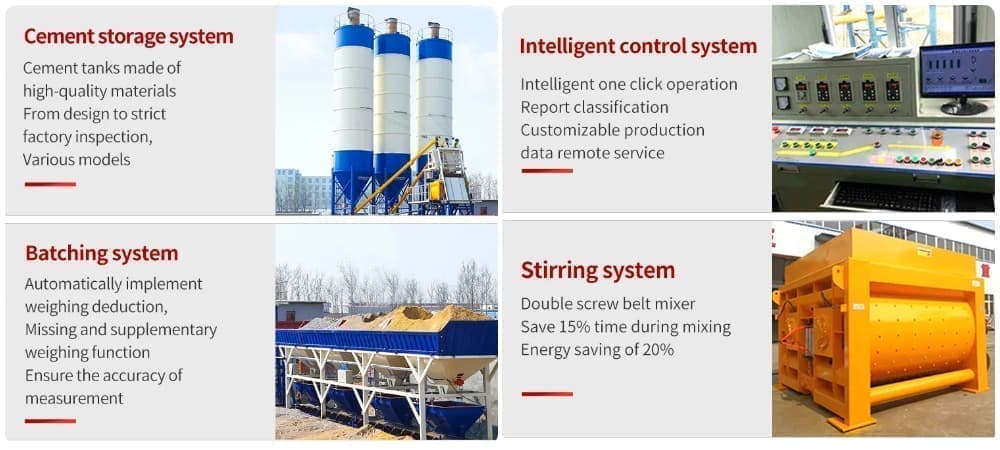

Product Benefits of Concrete Batching Plant Manufacturers

Ready-mix concrete batching plant is an automated production equipment that integrates material storage, weighing, conveying and mixing. It is capable of mixing raw materials such as cement, aggregate, water and admixtures into concrete according to preset ratios, which is widely used in the construction of buildings, roads, bridges and other projects.

The products of top ready-mixed concrete mixing plant manufacturers are usually characterized by the following features.

✔️ Stability and performance: the equipment operates stably to ensure the quality of concrete.

✔️ Precise Measurement: Ensure the accuracy of raw material proportioning.

✔️ Compact structure: saves space and is easy to install and move.

✔️ Intelligent control: Adopt advanced automatic control system to improve production efficiency.

✔️ High efficiency: shorten the mixing cycle and enhance the production capacity per unit time.

✔️ Long life: strong durability, reducing maintenance costs.

These features ensure that the mixing plant can produce high quality and stable performance concrete products, and at the same time, it has the advantages of easy operation and easy maintenance.

List of Top 10 Commercial Concrete Mixer Manufacturers in the World

The top ten ready-mix concrete mixing plant manufacturers listed here are leaders in the global construction machinery production industry. They include:

Ammann: Ammann is the world's leading manufacturer of commercial concrete mixers, machines and services for the road construction and transportation infrastructure building industries, with core expertise in road construction. The family-owned company has been internationally successful since 1869. Over time, Ammann has grown along with other brands, culminating in an integrated product line that offers complete solutions for the construction industry.

ASTEC: Founded in 1972, ASTEC is dedicated to applying creative thinking and state-of-the-art technology to traditionally low-tech industries, backed by a corporate culture known for putting customer service first. Headquartered in Chattanooga, U.S.A., the market-leading brand has become a global leader in the manufacture of equipment from rock to road.

SANY: SANY is one of the world's leading manufacturers of construction machinery and the world's largest manufacturer of concrete machinery. the name SANY comes from its corporate vision in Chinese: "To build a first-class enterprise, to cultivate first-class talents, and to make first-class contributions".

ELKON: Founded in 1975, ELKON has become a well-known brand in the field of concrete mixer manufacturing with a long history and experience. Since 2006, ELKON is the only concrete mixer manufacturer in Turkey.

MEKA: MEKA has been known for serving the aggregate and concrete industries since 1987. With its range of robust and reliable crushing and concrete mixing plants, MEKA engineers design and deliver solutions to meet the needs of real-world operators in a variety of applications and environments.

Putzmeister: Putzmeister is also one of the world's global leaders in construction and mining. For many years, they have developed, produced, marketed and serviced high-quality and highly reliable machines for concrete solutions. It is committed to serving its customers through business close to them and sees this as its mission for the future.

Schwing Stetter: Schwing Stetter GmbH was formerly a pioneering company specializing in the production and design of concrete mixers and concrete mixing plants, and in 1982 was acquired by the construction machinery giant Schwing as a subsidiary. Today, it has developed into a world-leading manufacturer of concrete construction equipment.

XCMG: Established in 1943, Xuzhou Construction Machinery Group Co., Ltd (XCMG) has been one of the leading companies in China's construction machinery industry since 1943. It has developed into one of the most influential and competitive enterprise groups with the most complete product range and series.

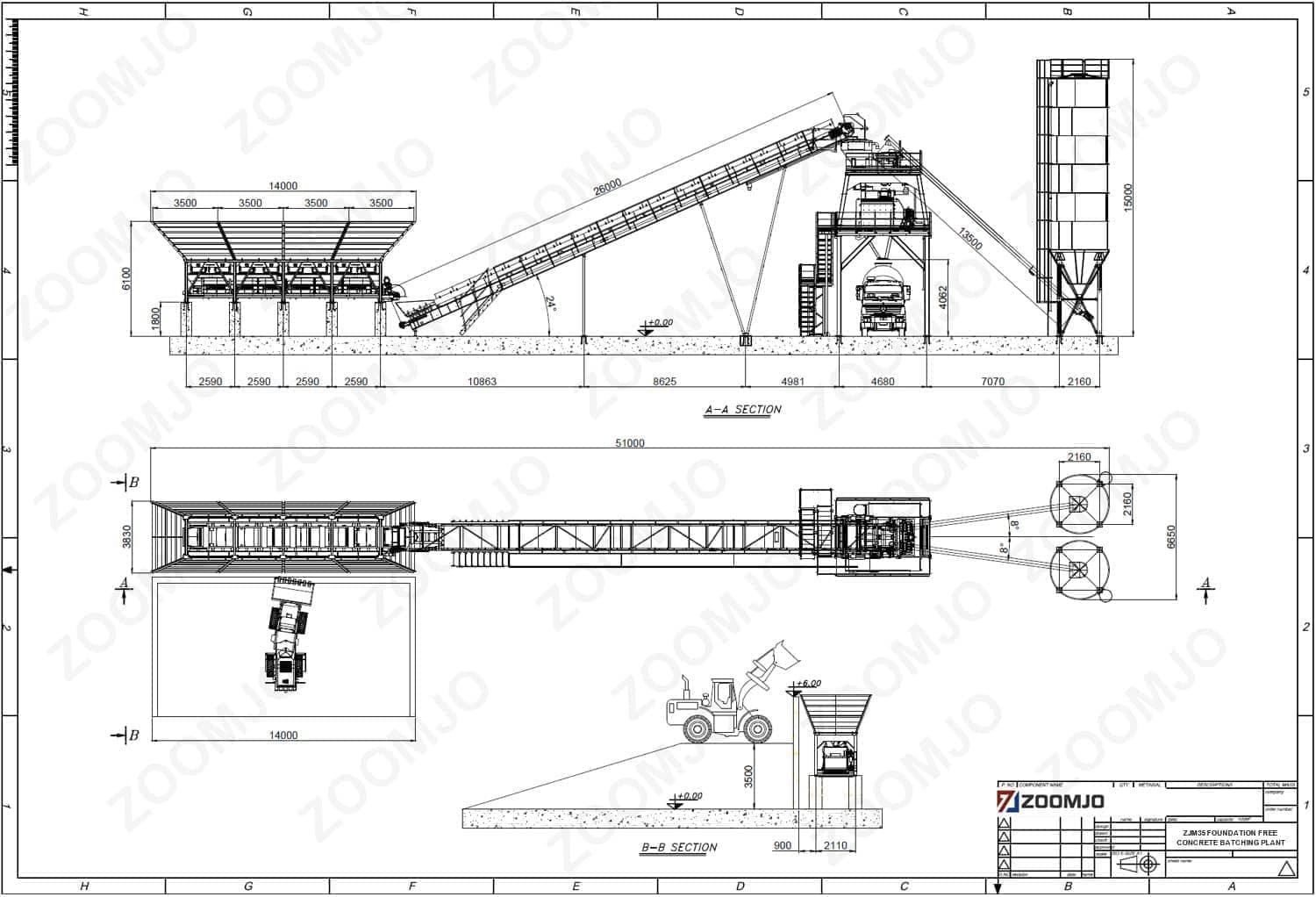

ZOOMJO: Since the foundation of ZOOMJO GROUP in 1995, ZOOMJO GROUP is now a leader in the construction machinery production industry, with more than 600 employees, including 100 researchers and technicians.30 For many years, ZOOMJO has been dedicated to the research, development and production of concrete machinery. The wide range of products includes stabilized soil mixing plants, asphalt mixing plants, concrete batching plants, concrete pumps, self-contained concrete mixer trucks, crushers, and more. Through hard work, more and more ZOOMJO products are known to customers all over the world. So far, ZOOMJO products have been exported to more than 100 countries and regions, and provide different concrete solutions for various construction projects.

NFLG Nanfang Road Machinery: Fujian Nanfang Road Machinery Co., Ltd (NFLG) is one of the leading companies in China's high-end equipment manufacturing sector. Established in 1997, for more than 20 years, NFLG has been engaged in a wide range of businesses including quarry design, construction material mining and crushing, shaping, and sand production lines, with products widely used in construction, transportation, water conservancy, and electric power industries.

These manufacturers hold a leading position in the global ready-mixed concrete mixing plant market, offering a wide range of efficient concrete mixing equipment to meet the needs of different construction projects.

Popular models of ZOOMJO ready mix concrete batching plant

Commercial mixer (RMC) batching plants available in the market today are usually equipped with powerful twin-shaft mixers, sophisticated weighing systems, compact modular structures and automatic control systems. All these excellent performance and features provide the market with high quality mixing performance, accurate batching ratios, stable product characteristics, long service life, easy maintenance, intelligent management and operation.

Popular Ready Mix Concrete Batching Plant Models

Skip Hopper RMC Plant

Model: HZS25/35/50/75

Production capacity: 25/35/50/75 m³/h

Batching machine: PLD800/1200/1600/2400

Maximum aggregate size: 80/60mm

Twin shaft mixer: JS500/750/1000/1500

Aggregate feeder: Hopper (Skip hopper)

Mixing cycle: 72 seconds

Belt Type RMC Batching Station

Model: HZS60/90/120/180/240

Capacity: 60/90/120/180/240 m³/h

Batching Plant: PLD1600/2400/3200/4800

Maximum aggregate size: 100/80mm or 120/80mm

Double shaft mixer: JS1000/1500/2000/3000

Aggregate feeder: belt conveyor

Mixing Cycle: 60 seconds

Model: ZJY25/35/50/60/75/90

Capacity: 25/35/50/60/75/90 m³/h

Batching Machine: PLD800/1200/1600/2400/3200/4800

Maximum aggregate size: 80/60mm or 100/80mm

Twin shaft mixer: JS500/750/1000/1500

Aggregate feeder: bucket or belt type

Mixing Cycle: 60 or 72 seconds

Stationary RMC Dosing Station

Model: HZS25/35/50/60/75/90/120/180/240

Capacity: 25/35/50/60/75/90/120/180/240 m³/h

Batching machine: PLD800/1200/1600/2400/3200/4800

Maximum aggregate size: 80/60mm or 100/80mm or 120/80mm

Twin shaft mixer: JS500/750/1000/1500

Aggregate feeder: Hopper (Skip hopper)

Mixing cycle: 60 seconds or 72 seconds

These different types of mixing plants are available for concrete production projects of all sizes and needs.

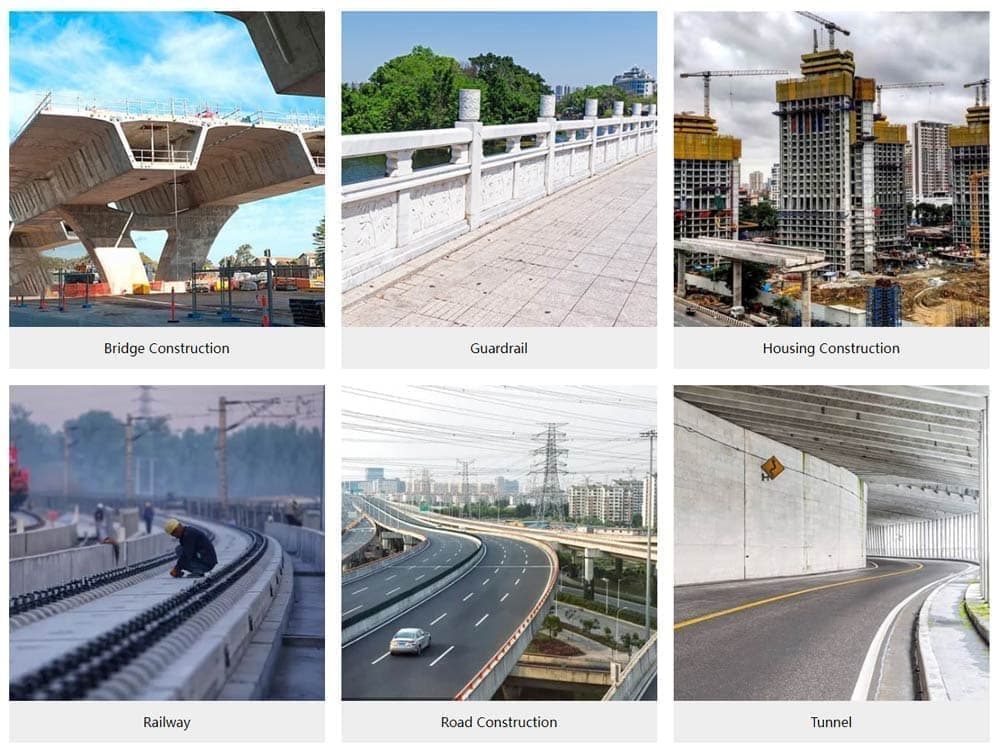

Application of ready-mixed concrete mixing plant

Ready-mixed concrete mixing plants have a wide and important application in modern building and infrastructure construction. They can provide large quantities of high-quality concrete for large-scale projects such as high-rise buildings, bridges and tunnels, and are also suitable for infrastructure construction such as roads, railroads and airport runways. For small and medium-sized residential and commercial construction projects, mobile mixing plants are particularly useful and can be flexibly deployed close to the construction site. In addition, they are used for the production of precast concrete components such as wall panels, beams and columns, as well as special concrete such as underwater concrete or impermeable concrete.

Advantages of Ready Mix Concrete Batching Plants

✅ Large and uniform production: Large-scale plants can produce fresh concrete in large and uniform batches. Accurate weighing of each batch ensures a high quality product.

✅ Efficient production: Automation of weighing and in-plant transportation enables efficient production.

✅ Efficient transportation: Since the plant can be located close to the construction site, there is no need for mixer trucks to transport the material over long distances. The required quantities can be supplied quickly.

RMC Plant Development trends

Future trends in ready-mixed concrete mixing plants include.

Miniaturization and mobility: Small and mobile plants will be the trend to meet the needs of projects of different sizes.

Intelligent: Managing and executing the entire workflow through human-machine interfaces.

Modular design: Compact modular structure for easy installation and maintenance.

Efficient Mixing: Equipped with powerful twin-shaft mixer to improve mixing performance and efficiency.

Accurate dosing: Precise weighing system ensures accurate dosing of ingredients.

Automation: Intelligent management and operation to improve production efficiency.

Conclusion

With the continuous advancement of technology and changing market demands, ready-mixed concrete mixing plant manufacturers will continue to lead the industry and provide customers with more efficient, environmentally friendly and smarter concrete mixing solutions. For more details about Ready Mix Concrete Batching Plant Manufacturer, please feel free to contact us.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська