RMC Plants Setup Cost

How much does it cost to set up a ready-mixed concrete mixing plant? This is a question that many investors are concerned about. This article will analyse in depth the various factors that affect the construction cost of a concrete mixing plant, and provide practical cost control strategies to help you minimise investment risk while gaining a good return.

RMC Plant Pricing

The cost of setting up a ready-mixed concrete (RMC) plant varies depending on the project size, equipment configuration, site conditions and other factors. Generally, it ranges from US$18,000 for a small mixing plant to US$250,000 for a large production line.

Construction Cost Analysis of Ready Mix Concrete Batching Plant

The construction cost of ready-mixed concrete batching plant is affected by many factors and is a complex systematic project. The main influencing factors include

-

Production capacity: The production capacity of different models of batching plants varies, and the cost is therefore different. The higher the production capacity, the more capital investment is required and the cost increases accordingly. Small and medium-sized plants usually have a capacity of no more than 90 cubic metres per hour, while large plants range from 120 to 240 cubic metres per hour.

-

Type and model of equipment: Before planning to invest in setting up an RMC plant, it is important to first determine the type and model of equipment that will suit the needs. Prices for different types and models of mixing plants vary considerably, ranging from US$15,000 to US$280,000.

-

Project Site Costs: In addition to the cost of the mixing plant itself, this includes the cost of the site and the cost of a closed raw material production area to meet environmental requirements.

-

Operating Costs: The production and operation of a concrete batching plant will also incur other costs such as utilities, staff wages, raw material costs and transport costs.

-

Other costs: other costs that may be incurred by the mixing plant during the whole operation process, such as maintenance costs.

Investment Value of RMC Batching Plant

With the booming construction industry, the demand for concrete is growing. As an indispensable raw material in construction projects, the quality and supply of concrete directly affects the overall progress and quality of construction projects. Therefore, investing in ready-mixed concrete mixing plant (RMC) has a broad market prospect.

Why invest in an RMC plant?

-

Strong market demand: Concrete, as a basic material for construction projects, has a huge and stable demand. With the acceleration of urbanisation, the demand for concrete will continue to grow.

-

High returns: RMC plants offer a high return on investment. Through large-scale production, automated operation and precise proportioning, production costs can be effectively reduced and profits increased.

-

Customised service: RMC plant can provide high performance and high quality customised concrete products according to customers' needs to meet the needs of different projects.

-

Technical Advantage: Advanced production equipment and technology can improve production efficiency, reduce energy consumption, and ensure product quality.

-

Environmental benefits: RMC plant adopts environmentally friendly process to reduce pollution to the environment, which is in line with the concept of sustainable development.

Factors to consider before erecting an RMC mixing plant

Before purchasing a ready-mix concrete plant, you need to carefully consider a number of perspectives to ensure that your investment decision is sound and the benefits are maximised. Below are some of the key factors for your decision making:

Plant type and cost

-

Stationary versus mobile: the choice should be based on the stability of the production requirements and the fixed nature of the site. Stationary is suitable for long-term, large-scale production; mobile offers flexibility between sites.

-

Equipment Configuration: This includes mixer specifications, batching accuracy, and level of automation, all of which have a direct impact on production efficiency and product quality.

-

Transport and installation: Consider the logistics costs of equipment from manufacturer to construction site, as well as installation and commissioning costs.

-

Supplier reputation: choose a reliable supplier who provides high quality equipment and good after-sales service.

Production requirements and scale

-

Production capacity: Ensure that the selected equipment can meet the maximum concrete demand of the project.

-

Types of concrete: Depending on the project requirements, different types of concrete may need to be produced and the equipment should be flexible accordingly.

-

Quality standards: Select equipment that meets the quality requirements of the concrete, such as strength and durability.

-

Site conditions

-

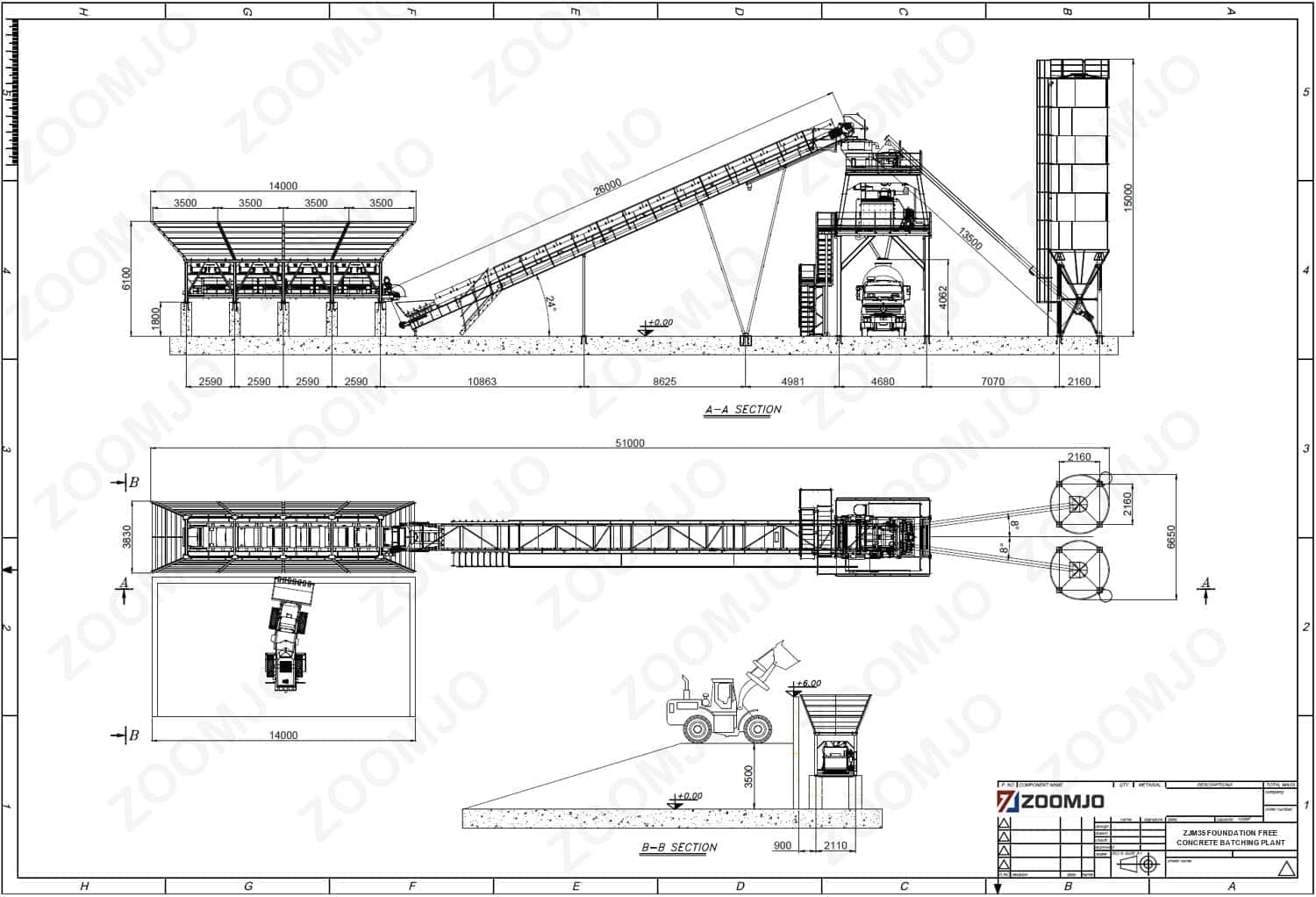

Site size: The site must be large enough to accommodate equipment, raw materials and product storage.

-

Infrastructure: Assess the site's water and electricity supply, transport links and drainage systems.

-

Environmental impact: Consider the impact of equipment operation on the surrounding environment and develop appropriate environmental protection measures.

Operating Costs

-

Labour costs: Estimate the cost of personnel required for operation, maintenance and management.

-

Energy consumption: Understand the cost of electricity, water and other energy sources and their impact on the total cost.

-

Raw Material Prices: Monitor the market price of raw materials such as cement and aggregates.

-

Maintenance: Set aside costs for equipment maintenance and unexpected repairs.

Policies and regulations

-

Environmental regulations: Ensure that equipment and production processes comply with local environmental regulations.

-

Land use policy: Acquire land use rights legally to avoid future legal risks.

-

Production Safety: Comply with production safety norms to reduce work accidents and liabilities.

How to reduce the investment cost of ready-mixed concrete (RMC) mixing plant?

Reducing the investment cost of a ready-mixed concrete (RMC) mixing plant is a multi-faceted process involving equipment procurement, site layout, raw material management, production efficiency and energy consumption. Here are some practical strategies:

1. Equipment selection and procurement

Equipment type and model: Depending on the size and needs of the project, choose a cost-effective small-scale mixing plant, such as HZS25 or HZS35, with a price range usually between US$15,000 and US$50,000.

Consider used equipment: Evaluate purchasing used equipment in good condition to minimise initial investment.

Moderate automation: Select moderate automation equipment that meets production needs to avoid over-investment.

2. Site Cost Optimisation

Site Selection: Prioritise sites close to raw material supplies to reduce transport costs, and consider leasing rather than purchasing sites.

Simplification of infrastructure: Simplify infrastructure to avoid unnecessary expenses while meeting production requirements and environmental standards.

3. Raw Material Cost Control

-

Multi-supplier strategy: co-operate with multiple suppliers and regularly evaluate prices and quality to ensure optimal purchasing costs.

-

Long-term supply contracts: Sign long-term contracts with suppliers to stabilise raw material prices.

-

Alternative Material Use: Explore the use of lower cost mineral powder and fly ash to replace part of the cement.

4. Production efficiency improvement

Regular equipment maintenance: Ensure the efficient operation of equipment and reduce faults and downtime.

Technology upgrading: Upgrade equipment at the right time to improve production efficiency.

Lean production process: Adopt lean production methods to reduce waste and improve resource utilisation efficiency.

5. Energy consumption reduction

Use of energy-saving equipment: Adoption of high-efficiency motors and pumps, and LED lighting systems.

Energy management system: Installation of energy monitoring systems and optimisation of production time to reduce energy costs.

Through the combined use of the above strategies, the investment cost of RMC mixing plant can be effectively reduced without sacrificing production quality and efficiency. Rational selection of equipment, optimisation of site use, control of raw material costs, enhancement of production efficiency, reduction of energy consumption and effective management of human resources are all key measures to reduce costs. This not only helps to improve the economy of the project, but also enhances the market competitiveness of the enterprise.

Recommended Types of ready-mixed concrete batching Plants

There are several main types of common ready-mixed concrete batching plants:

-

Stationary Batching Plant: This is the most common type and is suitable for long-term and large-scale concrete production projects. It has high productivity and stability.

-

Mobile Batching Plant: Mounted on a semi-trailer, it can be easily moved between sites. It is suitable for short-term projects or multiple projects that are close to each other.

-

Small-scale batching plant: suitable for small-scale or temporary concrete production needs, usually with low capacity but high flexibility.

-

Environmentally friendly batching plant: adopts advanced dust and noise control technology to reduce the impact on the environment.

-

Fully automated batching plants: use a computerised control system that allows precise control of the batching and mixing process, improving production efficiency and concrete quality.

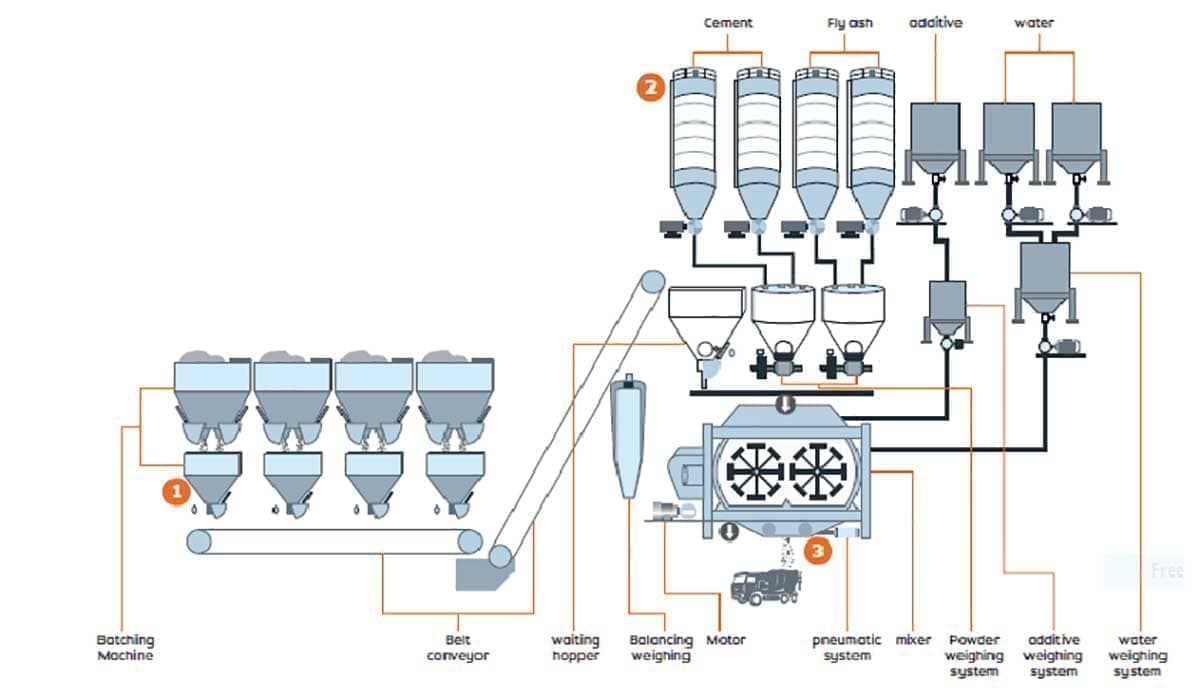

These batching plants usually consist of the following basic systems:

-

Feeding system: for storing and conveying various raw materials

-

Measuring (weighing) system: to accurately control the dosage of various materials

-

Mixing system: mixes the various materials into a homogeneous concrete

-

Electrical control system: co-ordinates the work of the various components

-

Auxiliary equipment: such as air compressors

Choosing the right type of RMC mixing plant requires consideration of factors such as the specific needs of the project, its size, geographical location and budget. By making a reasonable choice, the efficiency and economic benefits of the mixing plant can be maximised.

Who is your trusted RMC plant manufacturer?

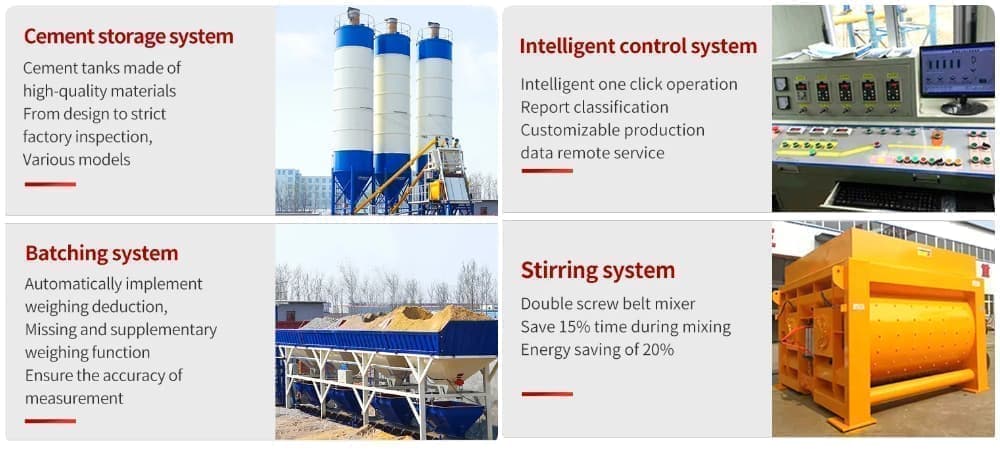

ZOOMJO, as one of the leading concrete mixing plant manufacturers in China, has been deeply involved in the industry for more than 20 years, and has always been committed to providing customers around the world with efficient, reliable and customised concrete mixing plant solutions.

Our Advantage:

-

Product Diversity: Covering a wide range of types such as RMC, stationary, mobile, belt, hopper, wet and dry, etc. to meet projects of different sizes and needs.

-

Excellent quality: sturdy structure, long service life, flexible configuration, accurate measurement, stable control, low noise, less dust, more environmentally friendly.

-

Customised service: From equipment selection to installation and commissioning, we provide a full range of customised services to ensure that the equipment matches your project perfectly.

-

Global service: Our products are exported to all over the world and are highly praised by customers.

-

Rich experience: We have accumulated rich experience in the industry and have 8000+ successful cases.

Why choose ZOOMJO?

-

Efficient production: Significantly improve your production efficiency and reduce operating costs.

-

Superior performance: Ensure stable and reliable concrete quality to meet high standards.

-

Attentive service: Professional team provides timely and efficient technical support and after-sales service.

Your needs, our attention. Contact ZOOMJO today and our experts will customise the best concrete mixing plant solution for your specific needs.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська