The Main Composition of Mobile Concrete Plant

Mobile concrete mixing plant is a kind of mobile concrete production equipment integrating silo, metering system, mixer, control system, conveying system and cement silo.

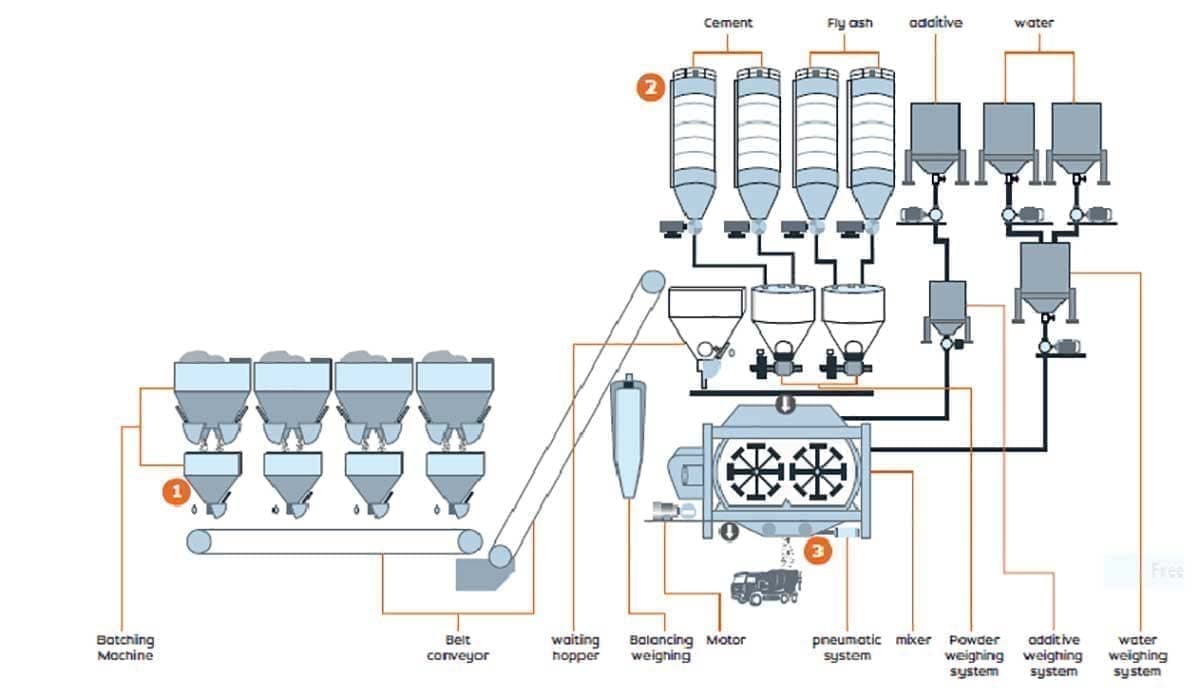

The main components of mobile concrete mixing plant are as follows:

1. Aggregate batching system: Aggregate metering adopts cumulative metering, which is completely accurate and reliable. Aggregate or concrete silo can be adapted to the needs of different grades of aggregate metering, and at the same time, it has high-precision sensors and automatic compensation function to ensure the accuracy of aggregate metering.

2. Control system: the whole mixing plant adopts industrial computer control with real-time data processing function. The system can be operated automatically or manually, which is simple and convenient. The interface simulates the whole dynamic process of the mixing plant, which is intuitive and clear. Various mixing and working data of the mixing plant can be stored and printed according to the report requirements.

3. Powder weighing: Cement and powder are fed into the powder weighing hopper by screw conveyor, and the weighing system is controlled by weighing instrument. After reaching the weight, the control system sends the command to stop the screw conveyor.

4. Water and Admixture Weighing System: Water is measured by high-precision sensors and then pumped into the weighing bucket from the water tank through the water filling pipe. After weighing, the water is transported to the mixing main pipe through two pipes. The principle of admixture weighing is basically similar to water weighing.

It has the following characteristics:

- Flexibility: the mobile concrete mixing plant can be transferred anywhere and anytime according to the project needs, no fixed installation foundation is needed, only a leveled site is needed. It can be adapted to various complex construction environments, such as roads, bridges, tunnels, water conservancy, electric power and so on.

- Efficiency: The mobile concrete mixing plant adopts advanced automatic control system, which can realize automatic or manual operation, which is convenient and quick. It can adjust the concrete proportion, output, quality and other parameters according to the user's needs to ensure the stability and consistency of concrete.

- Energy saving: all parts of the mobile concrete mixing plant adopt optimized design to reduce energy consumption and pollution. Its mixer adopts double-shaft forced mixing, which can improve the uniformity and strength of concrete while reducing the amount of cement. Its conveying system adopts closed conveying, which can prevent the spread of dust and noise and protect the environment and the health of personnel.

- Economy: Mobile concrete mixing plant has lower cost, easy maintenance and long life. It can flexibly adjust the production scale according to the actual needs, avoiding the waste and idleness of resources. It can save users a lot of human, material and financial resources and improve the return on investment.

Mobile Concrete Batching Plant Manufacturer

With its outstanding performance and flexibility, mobile concrete mixing plant has become the right hand of modern construction industry. Whether it is for bridge construction, road building or other infrastructure development, it is capable of producing high quality concrete quickly and accurately.

However, choosing a reliable supplier is essential to ensure the success of your project. zoomjo is a trusted brand. With its 28 years of experience and outstanding expertise, ZOOMJO is able to provide customers with high-quality and efficient concrete mixing plant equipment. Whether it is a stationary, mobile or foundationless concrete mixing plant, ZOOMJO is able to meet the needs of our customers and provide customized solutions.

Our products have been delivered to more than 105 countries and regions, such as the Philippines, Indonesia, Malaysia, Singapore, Sri Lanka, Ghana, Kyrgyzstan, Vietnam, Kazakhstan, Uzbekistan, Russia, Ukraine, Ethiopia, South Africa, Nigeria, Jamaica, Dominica, Australia, and so on.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська