How Much are Mobile Concrete Batching Plants? How Many Models are there?

Mobile concrete mixing plant is widely used in the construction of highway, bridge, water conservancy and other projects due to its convenient mobility and fast installation and dismantling characteristics. As a professional concrete mixing plant manufacturer, we often receive questions from customers about " What is the price of mobile concrete mixing plant? How many models are there? " We often receive customers' enquiry about "How much is the price of mobile concrete mixing plant? In this article, from the manufacturer's point of view, we will explain in detail the price influencing factors of mobile concrete mixing plant, common models and purchase considerations, and hope to provide valuable reference for your decision-making.

Price range of mobile concrete mixing plant

Based on our years of industry experience and market research, mobile concrete batching plants typically range in price from $38,000 to $150,000 USD. This price range spans a wide range and depends on several key factors:

-

Production capacity (capacity): This is the most significant factor affecting price. The higher the production capacity (e.g. from 25m³/h to 100m³/h), the higher the equipment configuration, mixer type, conveying system, etc. required, which leads to a significant increase in price. For example, a YHZS25 model (25m³/h) may cost around $35,000, while a YHZS90 model (90m³/h) may cost more than $150,000.

-

Functionality: The level of automation, the mixing technology used, whether silos are integrated or not, and other additional features (e.g., dust extraction system, monitoring system, etc.) all affect the price. The higher the level of automation and the better the features, the higher the price.

-

Brands and manufacturers: Prices can vary between brands, even if the capacities are similar. This is related to the manufacturer's technical strength, production process, after-sales service and other factors.

-

Degree of customisation: With the increasing diversification of engineering needs, users have higher and higher customisation requirements for equipment. Customised configurations, such as special aggregate batching systems, mixer types, control systems, etc., will directly affect the final purchase cost.

The budget for a mobile concrete mixing plant not only includes the purchase cost of the equipment itself, but should also cover a range of additional costs such as transport, installation, maintenance and spare parts. These costs may add up to a considerable amount of expenditure, directly affecting the overall return on investment of the project.

Therefore, in order to avoid budget overspending and later operation troubles, it is strongly recommended to communicate with reputable suppliers in depth before purchasing the equipment, to understand the estimation of each cost in detail, and to choose the most suitable equipment configuration and after-sales service programme according to your actual needs.

Planning a project? Let us provide you with professional mixing plant solutions!

Common Models of Mobile Concrete Batching Plants

The models of mobile concrete mixing plant are usually named by their theoretical production capacity, such as YHZS25, YHZS35, YHZS50, YHZS75, YHZS100, etc. The prefix " YHZS " is the common model of mobile concrete mixing plant. Among them, "YHZS" is the common prefix of mobile concrete mixing plant models, and the number after it represents its hourly theoretical production capacity (unit: cubic metre/hour).

| Model | Capacity (m³/h) | Discharge height (mm) | Installed power (kW) |

|---|---|---|---|

| YHZS25 | 25 | 3800 | 35.55 |

| YHZS35 | YHZS35 | 3800 | 47.05 |

| YHZS50 | 50 | 3800 | 61.75 |

| YHZS75 | 75 | 3800 | 88.75 |

| YHZS100 | 100 | 3800 | Depends on the configuration |

It should be noted that the above parameters are for reference only, the specific parameters may vary depending on the manufacturer and configuration.

Want to know the specific parameters and price of YHZS series mixing plant? Contact us now!

Core advantages of mobile concrete mixing plant

-

Easy dismantling and transport: With modular design, the main components are integrated into the chassis, which can be quickly transported by trailer without tedious dismantling work. Typically, the installation of the plant can be completed in just 3 days, which greatly reduces the construction preparation period.

-

Efficient mixing performance: Equipped with the excellent JS series double horizontal shaft forced mixer, it has the advantages of fast mixing speed, even mixing and high mixing quality, and can efficiently mix all kinds of dry, plastic and flowable concrete to meet the needs of different projects.

-

Significantly reduce infrastructure costs: Compared with the stationary mixing plant, the mobile mixing plant requires less foundation and does not need to carry out large-scale concrete foundation construction, which significantly reduces the investment in infrastructure construction and reduces the site constraints.

-

Excellent Adaptability and Flexibility: Strong mobility is its biggest advantage, especially suitable for projects with tight schedule, scattered construction sites, and frequent transshipment, such as infrastructure construction of highways, railways, bridges, tunnels, hydropower and other infrastructure construction, as well as construction in the field or remote areas.

Precautions for choosing mobile concrete mixing plant

-

Clarify the project requirements: Before purchasing, make sure you fully understand the concrete consumption, construction period, site conditions, etc., so as to determine the appropriate production capacity and equipment configuration.

-

Pay attention to the quality of the equipment: choose a reputable manufacturer and pay attention to the quality and performance of each component of the equipment (e.g. mixer, batching system, control system, etc.).

-

Consider after-sales service: Good after-sales service is crucial to the long-term stable operation of the equipment. Choose the manufacturer who can provide timely and effective technical support and spare parts supply.

-

Consider the cost comprehensively: in addition to the initial purchase cost of the equipment, the subsequent costs such as transport, installation, maintenance and spare parts should also be considered for a comprehensive assessment.

-

Consult professionals: If necessary, consult professional concrete mixing plant manufacturers or suppliers for professional advice and quotations.

To summarise

The price and model selection of mobile concrete mixing plant is a decision-making process that requires comprehensive consideration of many factors. We hope this article can help you better understand the market situation and product characteristics of mobile concrete mixing plant, so as to make a wise choice. If you have any questions or needs about mobile concrete mixing plant, please feel free to contact us, we will be happy to serve you.

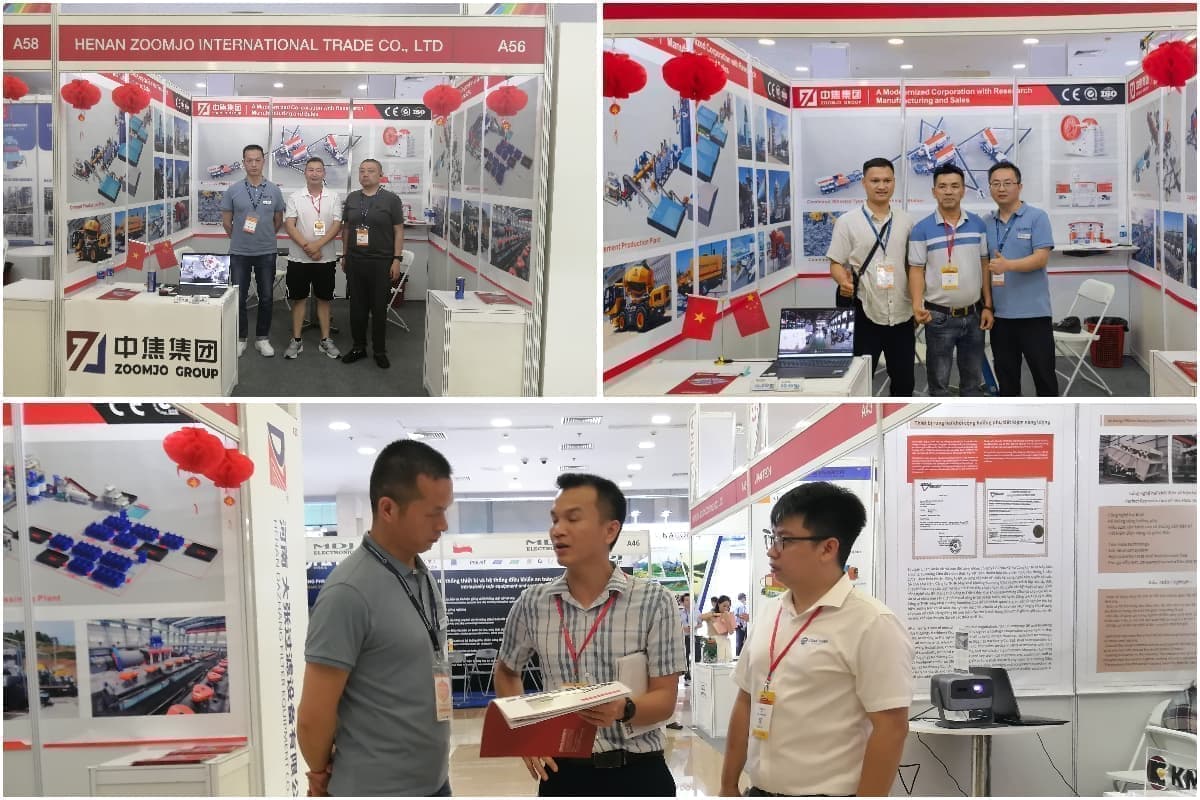

About Us

ZOOMJO GROUP is a leading global construction machinery company, with concrete machinery as one of its core businesses. The company offers a comprehensive product line of concrete mixing plants designed to meet the different needs of a wide range of construction projects.

Product Type

-

Stationary Concrete Batching Plants: Suitable for large-scale, long-term projects with strong production capacity and excellent stability.

-

Mobile Concrete Batching Plant: Designed for projects that require frequent transfers, it is easy to install and can be put into operation quickly.

-

Project Batching Plants: Customised to meet the specific needs of a particular project and to meet the most demanding construction requirements.

-

Commercial Concrete Mixing Plant: Focusing on the production and sale of commercial concrete to fully meet market demand.

Product Features

-

Advanced technology: ZOOMJO has accumulated a wealth of experience in the field of mixing technology, and its products adopt the advanced technology of high efficiency mixing, precise dosing and intelligent control.

-

Reliable Performance: All products have been rigorously tested to ensure stable and reliable operation in various complex environments.

-

Energy-saving and environmental protection: The application of advanced dust removal and noise reduction systems effectively reduces the impact on the environment and significantly improves the working environment.

-

Perfect after-sales service: We have built an efficient after-sales service network, which can provide professional technical support and maintenance service in time.

If you are looking for high quality and efficient concrete mixing solutions, ZOOMJO GROUP is your ideal partner. Our professional team is committed to providing you with tailor-made equipment and services to fully meet your specific needs. Feel free to contact us for more product information and quotation!

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська