Mobile Concrete Plants: Ukraine's Best Deals

The demand for efficient and reliable concrete production solutions continues to grow in Ukraine's booming construction industry. As an industry expert, I have noticed the rising popularity of mobile concrete mixing plants in the Ukrainian market, which have become an integral part of modern construction projects thanks to their reasonable prices and quality assurance. They provide the flexibility and efficiency needed to meet tight deadlines and diverse project requirements.

Mobile Concrete Batching Plants in Ukraine

As the infrastructure construction in Ukraine continues to advance, cost-effective mobile concrete mixing plants with strict quality control systems have become an important strategic investment for construction companies to improve their operational efficiency. As an expert in the field of building construction equipment, I have noticed that the market demand for mobile concrete mixing plants is steadily growing. This type of equipment has become an indispensable core equipment for modern building construction, and can effectively meet the industry's urgent demand for diversified and highly efficient production.

Against the backdrop of Ukraine's improving infrastructure and increasing urbanisation, reliable and trustworthy concrete production solutions are more important than ever.

What is a mobile concrete mixing plant?

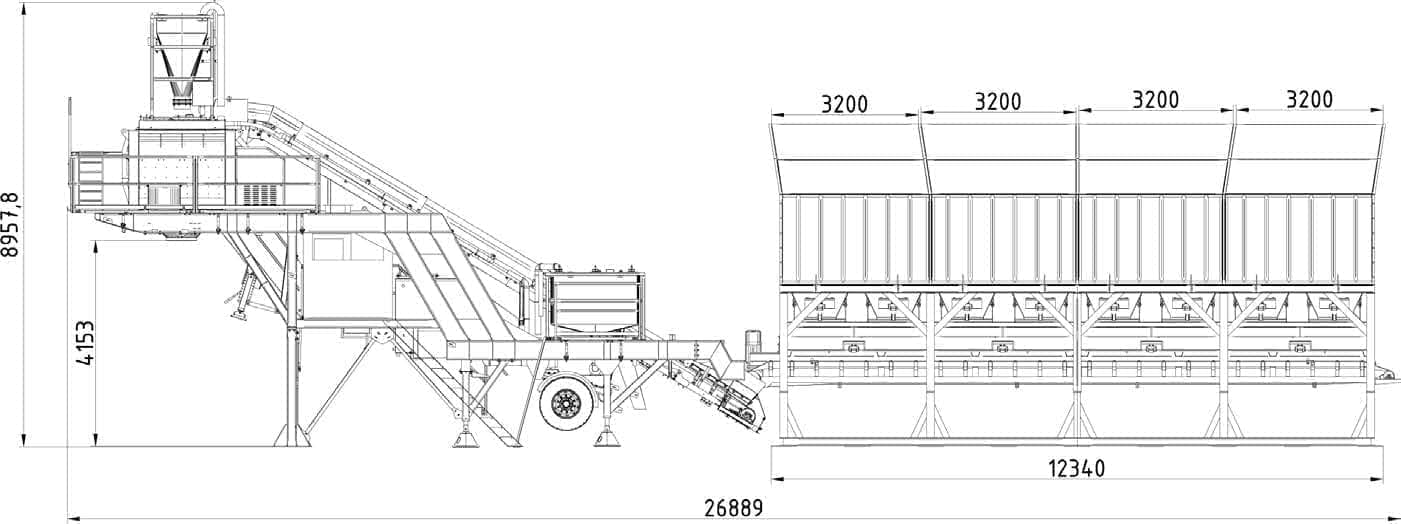

Mobile Concrete Batching Plant is a portable and efficient concrete production equipment designed for projects that require frequent turnaround and short-term construction. It highly integrates raw material storage, weighing, conveying, mixing, discharging and intelligent control system in a single trailer unit, which can be regarded as a small concrete mixing plant mounted on a mobile platform, thus realising flexible transfer of production equipment.

Compared to a stationary batching plant, a mobile batching plant can be easily moved to different locations, making it particularly suitable for projects that require constant transshipment or are located in remote areas. Although mobile batching plants are superior to fixed ones in terms of flexibility, their structural design is similar.

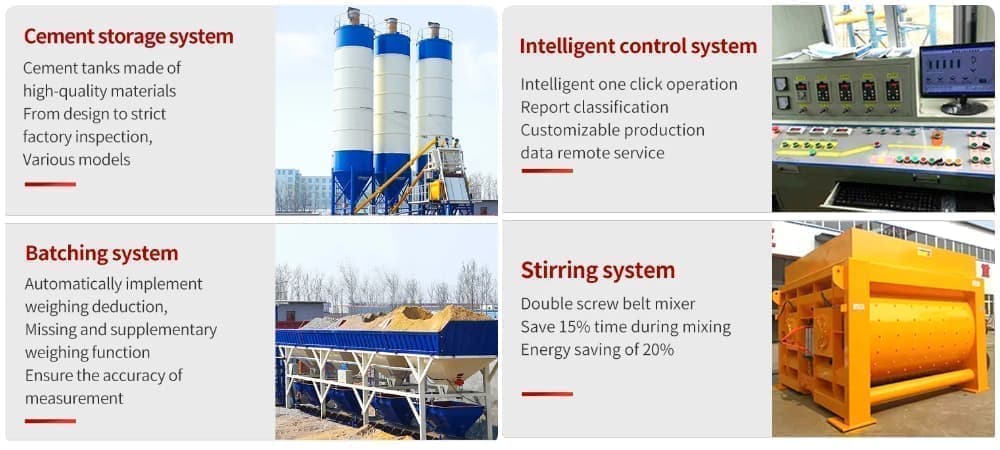

The main components of a mobile concrete mixing plant include the following core systems, each of which plays an important role in the production of concrete:

Aggregate silo

Aggregate bins are used to store various types of aggregates such as sand and stone. Typically, aggregate bins can be divided into multiple compartments to allow for the categorisation and storage of different types of aggregates, ensuring that the required materials can be accessed quickly and accurately during the production process.

Cement silos

Cement silos are used to store cement and are usually designed as sealed structures to prevent moisture and loss of cement. The capacity and number of cement silos can be adjusted according to production requirements to meet different scales of concrete production.

Batching System

The batching system is responsible for accurately weighing a variety of raw materials, including aggregates, cement, water and admixtures. Typically consisting of multiple weighing hoppers and conveying equipment, the system automates the batching process and ensures that the proportions of each material are in accordance with the pre-determined recipe.

Mixing Systems

The mixing system is the core part of a mobile concrete mixing plant, responsible for mixing various raw materials to produce high-quality concrete. Commonly used mixer types include double horizontal shaft forced mixers and vertical shaft planetary mixers, which are capable of completing the mixing task quickly and evenly.

Control System

The control system is used to monitor and control the operation of the whole mixing plant to ensure the automation and intelligence of the production process. Modern control systems are usually equipped with PLCs (programmable logic controllers) and human-machine interfaces, which are able to monitor the status of each link in real time and carry out data recording and analysis.

Together, these components form a complete system of the mobile concrete mixing plant, enabling it to efficiently and flexibly meet various construction needs.

Current market landscape in Ukraine

In Ukraine, the market for mobile concrete mixing plants is expanding rapidly. This growth is attributed to the country's focus on infrastructure development and innovations in the construction industry. Mobile concrete batching plants are a popular choice among service providers and construction contractors due to their favourable pricing and stringent quality control. Scenarios for its application include large-scale infrastructure projects, road and bridge construction, water conservancy projects, temporary construction projects, and construction in remote areas. This flexible equipment configuration makes mobile concrete mixing plants useful in a wide range of construction environments.

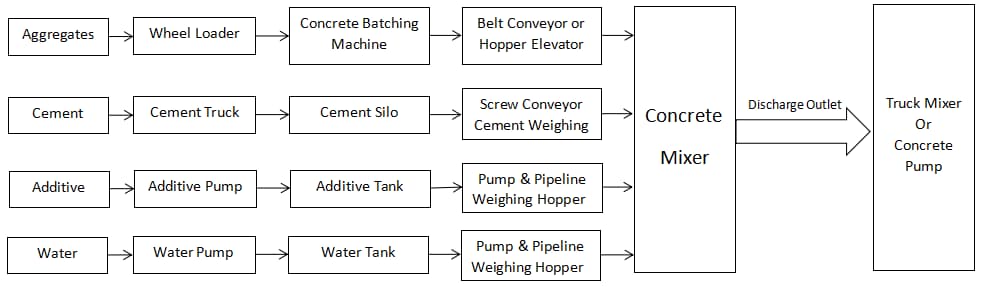

Working Principle of Mobile Concrete Batching Plant

The working principle of the mobile concrete mixing plant consists of the following steps, which are designed to achieve efficient and continuous concrete production:

Raw material preparation

Before starting the mixing process, various raw materials (e.g. aggregates, cement, water and admixtures) need to be prepared first. Aggregates (e.g. sand and gravel) are fed into the storage hopper by means of conveying equipment, while cement is stored in a special cement silo.

Weighing system

The mobile concrete mixing plant is equipped with an accurate weighing system. Based on a pre-set recipe, the system automatically weighs the required raw materials such as aggregates, cement and water to ensure that the proportions of each material meet the requirements. This process is usually done by multiple weighing hoppers and conveyors for automated batching.

Mixing process

After weighing, all raw materials are fed into the mixer for mixing. Mobile mixing plants usually use double horizontal shaft forced mixers, which can mix various raw materials quickly and evenly to produce high-quality concrete.

Discharge

Once the mixing is complete, the concrete is discharged through the discharge opening and is usually loaded directly into a concrete truck for easy transport to the construction site. The entire discharging process is also automated to ensure efficiency and accuracy.

The entire production process is monitored and managed by an automated control system. The control system usually includes a PLC (Programmable Logic Controller) and a human-machine interface, which is capable of monitoring the status of each step in real time, as well as recording and analysing data. The application of such systems improves production stability and efficiency.

Through the above steps, the mobile concrete mixing plant is able to produce concrete quickly and flexibly at different construction sites to meet the needs of various projects. The compactness and efficiency of its design make it an indispensable equipment in modern building construction.

Benefits of Mobile Concrete Batching Plant

Mobile concrete batching plants offer many benefits that make them a popular choice for many construction projects:

| Advantages | Description |

|---|---|

| Transportability | Easy to carry and set up in different locations, reducing logistics costs. |

| Flexibility | Ability to produce a variety of concrete mixes to meet different project requirements. |

| Performance | Enables quick set-up and dismantling, reducing downtime and optimising performance. |

| Economy | Offers favourable pricing and reduces the need for multiple stationary mixing plants. |

Mobile concrete mixing plants are an important asset for the Ukrainian construction market. Their versatility, cost-effectiveness and reliability make them a strategic investment for any building and construction company aiming to improve its operations.

Characteristics of mobile concrete batching plants

Mobile concrete mixing plants are becoming increasingly popular in Ukraine due to their flexibility and efficiency. These mixing plants are designed to be transported quickly and set up on multiple construction sites, making them ideal for projects that require mobility and quick setup. Let's take an in-depth look at the key features that make these mixing plants the preferred choice for many professionals.

Portability and ease of transport

One of the outstanding features of mobile concrete mixing plants is their transportability. These mixing plants are mounted on a chassis and can be easily moved from one location to another. This feature significantly reduces the time and cost involved in transporting concrete from a fixed mixing plant to a construction site. The compact design ensures that they can be transported using standard trucks for seamless logistics.

Quick installation and set-up

Mobile concrete mixing plants are designed for quick installation. With minimal foundation requirements, they can be set up and operational in a very short period of time. This quick set-up is vital for projects with tight deadlines, allowing contractors to begin concrete production almost immediately upon arrival at the site.

Integrated control system

These mixing plants are equipped with advanced control systems that aid in accurate concrete proportioning and mixing. The control systems are usually electronic and allow automating the process and tracking the entire proportioning process. This ensures consistent quality of concrete and helps in maintaining the required concrete mix requirements.

High production capacity

Despite their small size, mobile concrete mixing plants have high production capacity. They are able to efficiently produce a wide range of concrete mixtures to meet the needs of different construction projects. The ability to produce large quantities of concrete without sacrificing quality makes them a great asset on any construction site.

Durability and sturdy construction

Manufacturers of mobile concrete mixing plants ensure that these units can withstand harsh weather conditions and the rough environment of constant transport. Sturdy construction and the use of quality materials ensure a long life for the equipment, providing good value for the investment.

Cost Effectiveness

Another important feature of mobile concrete mixing plants is their cost-effectiveness. By eliminating the need for multiple stationary mixing plants and reducing transport costs, these plants offer a more economical option for concrete manufacturing. Their ability to produce concrete on-site also reduces waste, providing further cost savings.

In summary, the key features of mobile concrete mixing plants, including their mobility, ease of set-up, integrated control systems and cost-effectiveness, make them an attractive option for Ukrainian professionals. These features ensure that construction projects can be carried out efficiently and effectively, meeting the demands of modern construction technology.

Benefits of choosing mobile concrete batching plant

Flexibility and transportability

One of the biggest benefits of mobile concrete batching plants is their flexibility and transportability. These mixing plants are designed to be moved quickly and set up on different construction sites, making them suitable for projects that require frequent relocation. This transportability ensures that you can produce concrete at the specific location where it is needed, minimising transport costs and time delays.

Cost Effectiveness

Mobile concrete mixing plants offer an economical solution for construction companies. By purchasing a mobile mixing plant, you can reduce the costs associated with transporting concrete from a fixed mixing plant to a construction site. In addition, the ability to produce concrete on-site reduces waste and ensures that the mixture is fresh and of the highest quality, further reducing costs.

Quick installation and set-up

The design of mobile mixing plants allows for quick installation and set-up. Unlike traditional stationary mixing plants, which can take days or even weeks to install, mobile mixing plants can be up and running in a matter of hours. This quick start-up is particularly useful for projects with tight deadlines or in remote areas where time is of the essence.

High efficiency and productivity

Mobile concrete mixing plants are equipped with advanced technology that ensures high performance and productivity. These mixing plants are capable of producing large quantities of concrete at a consistent quality to meet the needs of multiple construction projects. The automation features found in many modern mobile mixing plants also reduce the need for manual work, increasing efficiency while maintaining accuracy.

Environmental Benefits

Another benefit of mobile concrete mixing plants is their environmental impact. By producing concrete on-site, these mixing plants reduce the need for transport, which in turn reduces fuel consumption and emissions. In addition, many mobile mixing plants are equipped with environmentally friendly innovations that reduce waste and conserve resources.

Adaptability of applications

Mobile concrete mixing plants are flexible enough to be used for a variety of applications ranging from small residential projects to large infrastructure developments. Their adaptability to different project requirements makes them a great asset for construction companies to expand their capabilities.

| The Benefits | Summarise |

|---|---|

| Versatility and transportability | Easy to transport and configure across sites. |

| Cost Effectiveness | Reduces transport costs and minimises waste. |

| Quick installation | Ready for use in a few hours, suitable for tight schedules. |

| High efficiency | Advanced technology ensures consistent quality and output. |

| Environmental benefits | Reduce emissions and conserve resources. |

| Convenience | Suitable for a variety of building and construction applications. |

Factors to consider when buying a mobile concrete mixing plant

Capacity and output

One of the key factors to consider when purchasing a mobile concrete batching plant is its capacity and output. Evaluate your project needs and select a mixing plant that can meet your desired production levels. The capacity of the mixing plant should match the size of your construction project to ensure efficiency and cost-effectiveness.

Mobility and flexibility

The essence of a mobile concrete mixing plant is its ability to move quickly. Check the flexibility features of the mixing plant, such as chassis type, wheels and towing capacity. This flexibility is vital for projects that require constant site changes, allowing you to save time and reduce transport costs.

Ease of installation and operation

When choosing a mobile concrete batching plant, consider ease of installation and operation. Batching plants with simple interfaces and uncomplicated setup processes will reduce downtime and labour costs. Look for designs that offer automated controls and clear instructions to facilitate a smooth process.

Durability and build quality

The durability and build quality of a mixing plant is critical to a long-term investment. Ensure that the materials used to construct the mixing plant are robust and able to withstand the rough conditions of the construction environment. Quality components will reduce maintenance requirements and extend the life of the equipment.

Cost and cost-effectiveness

While the initial investment is an important factor, it is also important to evaluate the price in relation to the features and benefits of the mixing plant. Choose a mobile concrete mixing plant that offers beneficial pricing without compromising quality and performance. Consider long-term savings in maintenance and operating costs as part of your investment decision.

High quality assurance and certification

Ensure that your mobile concrete mixing plant comes with quality assurance and meets market standards. Look for accreditation from reputable organisations that verify the efficiency and safety of the mixing plant. A certified mixing plant will provide confidence and ensure reliable operation.

Distributor reputation and support

Finally, choose a supplier that has a good reputation in the market. Research their performance record and customer reviews to determine their reliability and quality of service. A reputable supplier will provide excellent after-sales service, including maintenance services and spare parts supply, ensuring optimum performance of your mobile concrete batching plant.

Price comparison of mobile concrete batching plants in Ukraine

When considering purchasing a mobile concrete batching plant in Ukraine, it is essential to understand the pricing landscape. The cost of these mixing plants can vary significantly based on a number of variables, including capacity, brand, and additional features. Below, we explore a detailed price comparison to guide potential buyers in making an informed decision.

Factors Affecting Price

The cost of a mobile concrete batching plant is affected by many key factors:

-

Capacity: Batching plants with greater production capacity tend to be more expensive because they are able to handle larger volumes of concrete.

-

Brand: Well-known brands usually charge a premium for their reputation and credibility.

-

Features: Advanced features such as automation, enhanced mobility and energy efficiency may increase the total cost.

Price range

The table below details common cost ranges for mobile concrete batching plants available in Ukraine:

| Capacity (cubic metres per hour) | Price range (USD) |

|---|---|

| 20-30 | 25,000 - 35,000 |

| 30-50 | 35,000 - 50,000 |

| 50-75 | 50,000 - 70,000 |

| 75-120 | 70,000 - 100,000 |

Comparative analysis

When comparing costs, it is important to consider not only the initial cost, but also the long-term value. A slightly more expensive mixing plant may offer better durability and efficiency, leading to cost savings over time. In addition, consider the availability of after-sales service and warranty solutions, which can significantly impact the total cost of ownership.

Economic Buying Tips

To ensure an economical purchase, potential buyers must:

-

Assess needs: clearly define production requirements to avoid overpaying for unnecessary capacity.

-

Research suppliers: Compare multiple suppliers to find affordable prices and aggressive terms.

-

Consider financing options: Explore financing services to make purchasing easier.

By understanding the pricing features and considering all relevant aspects, buyers can ensure that the mobile concrete batching plants they buy in Ukraine offer the best balance of cost and quality control.

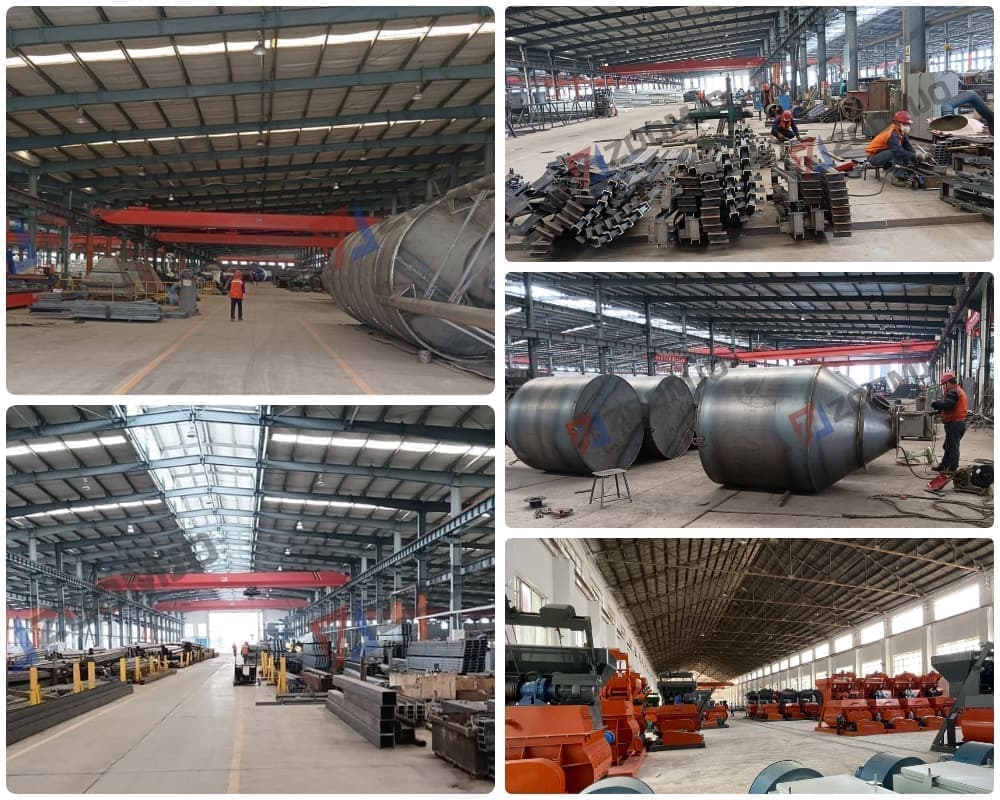

Quality control in mobile concrete batching plant manufacturing

When considering buying a mobile concrete batching plant for sale in Ukraine, it is essential to understand the importance of quality control in the manufacturing process. Ensuring that the mixing plant meets the highest standards of quality issues is critical to achieving optimal performance and long life.

The value of quality assurance

Quality control in production not only ensures that a mobile concrete batching plant is built to last, it also ensures that it operates efficiently under a wide range of conditions. This includes rigorous testing and adherence to international standards, which significantly reduces the risk of operational failures and costly downtime.

Standards and certifications

Manufacturers of mobile concrete mixing plants in Ukraine usually follow internationally recognised standards such as ISO 9001.This certification is proof of a company's commitment to maintaining a quality management system. In addition, compliance with the CE marking indicates that the equipment meets the safety, health and environmental protection requirements of the European Union.

Materials and components

The quality of the materials and components used in the construction of a mobile concrete batching plant plays an important role in its overall reliability. Trustworthy manufacturers use high-grade steel and durable components to withstand the rough conditions of the construction environment. In addition, components like mixers, conveyors and control systems are sourced from reliable suppliers to ensure consistent performance.

Inspection and testing

Before a mobile concrete mixing plant is delivered to a consumer, it undergoes thorough testing and evaluation. This process includes checking the capabilities of all components, ensuring the accuracy of the ratios, and confirming that the batching plant complies with environmental regulations. This strict attention to detail ensures that the batching plant is delivered ready for immediate use.

After Sales Service

Quality assurance does not end with the end of the production process. Reliable suppliers offer strong after-sales support, including maintenance services and the supply of additional components. This support is vital to keep concrete plants efficient and extend their operational life, providing customers with confidence and protecting their investment.

In conclusion, when evaluating mobile concrete mixing plants for sale in Ukraine, it is vital to prioritise a high quality guarantee for the production process. It ensures that the mixing plant will meet the needs of your project while providing reliable and trustworthy services for concrete manufacturing.

Main suppliers of mobile concrete mixing plants in Ukraine

In Ukraine's vibrant construction sector, choosing the right supplier of mobile concrete mixing plants is crucial to ensure reasonable pricing and quality control. The market has a number of reputable suppliers and distributors offering a range of products tailored to different project requirements. Below is a detailed review of some of the major suppliers in Ukraine, highlighting their key products and benefits.

Key suppliers and their products

Many companies have positioned themselves as leaders in the supply of mobile concrete batching plants in Ukraine. These suppliers are known for their commitment to high quality, customer service and affordable prices. Below is a list of some of the top suppliers:

| Supplier | Key Features | Price range (USD) | Quality Assurance |

|---|---|---|---|

| ZOOMJO | High mobility, automatic control, compact layout | 30,000 - 50,000 | ISO 9001 certified / CE marked |

| UkrStroyTech | Energy efficient, easy to maintain, robust construction | 25,000 - 45,000 | CE marking |

| PromStroyTech | Fast configuration, customised arrangements, reliable output | 28,000 - 48,000 | ISO 14001 certified |

| StroyBeton | Durable product, advanced mixing technology, simple user interface | 35,000 - 55,000 | High Quality Management System Certification |

Factors to consider when selecting a supplier

When selecting a supplier, it is necessary to consider a number of factors that may affect the overall success of a construction project. These factors include:

-

Reputation: look for suppliers with a strong track record and positive customer reviews.

-

Support services: Ensure that the supplier offers a detailed after-sales service, including maintenance and spares availability.

-

Customised options: some projects may require specific arrangements; check that the distributor can meet these requirements.

-

Delivery times: Timely delivery is vital to keep projects on schedule, so verify the supplier's lead times.

By carefully evaluating these factors and considering products from top suppliers, you can make informed decisions that align with your project needs and budget constraints. This approach ensures that you invest in a mobile concrete batching plant that offers favourable pricing and quality control, contributing to the success of your construction business in Ukraine.

Ways to ensure optimal performance of your mobile concrete batching plant

Ensuring optimal performance of your mobile concrete batching plant is essential to maximising efficiency and productivity. Whether you operate in Ukraine or elsewhere, following best practices can significantly increase the life and capacity of your equipment. Here are some key methods to consider:

Regular maintenance and inspections

Regular maintenance is essential to keep your mobile concrete batching plant in top condition. Establish a regular inspection schedule to identify and address any wear and tear or potential issues before they escalate. Key components to keep a close eye on include the mixer, delivery system and control panel. Implementing a preventative maintenance programme can reduce downtime and extend the life of your mixing plant.

Proper Calibration

Accurate calibration of your mixing plant is essential to ensure the correct proportioning of materials. Scopes and sensors are adjusted regularly to maintain the consistency and quality of the concrete produced. This is especially important when working with different types of aggregates and concrete that may vary in weight and density.

Training and skills development

Well-trained operators are better at recognising potential problems, performing efficient operations and implementing safety and security measures. Consider regular training expertise to keep your team up to date with the latest technology and best practices.

Use quality materials

The quality of the concrete produced is directly related to the quality of the materials used. Make sure you source quality resources from reliable suppliers. This not only improves the strength of the concrete, but also the overall performance of the mixing plant.

Tracking and control systems

Advanced tracking and control systems provide real-time data on mixing plant performance. Use these systems to track production metrics, identify deficiencies, and make informed decisions. Implementing automated control systems can also reduce human error and improve operational efficiency.

Environmental Considerations

Operating a mobile concrete batching plant in accordance with environmental regulations is essential. Implement soil and noise control measures to minimise environmental impact. In addition, consider the use of environmentally friendly products and methods to increase sustainability.

| Key Practices | Advantages |

|---|---|

| Regular maintenance | Reduce downtime and extend equipment life |

| Correct calibration | Ensure concrete consistency and quality |

| Train operators | Improve efficiency and safety |

| Quality materials | Enhance strength and performance |

| Tracking Systems | Provides real-time data for informed decision making |

| Environmental Compliance | Reduce environmental impact |

By implementing these methods, you can ensure that your mobile concrete batching plant is operating at optimum efficiency, producing quality concrete efficiently and sustainably. This not only improves your operations, but also provides a competitive advantage in the marketplace.

Frequently Asked Questions about Mobile Concrete Batching Plants for Sale in Ukraine

What is a mobile concrete batching plant?

A mobile concrete batching plant is a compact and versatile system designed to produce concrete directly on site. It is easy to transport, making it ideal for projects that require frequent relocation or are located in remote areas.

What are the main advantages of using a mobile concrete batching plant in Ukraine?

Mobile concrete batching plants offer a variety of advantages, including transportability, flexibility, efficiency and cost-effectiveness. They allow for easy transport and setup, can produce a wide range of concrete mixtures, and reduce logistics costs.

How does a mobile concrete batching plant ensure quality assurance?

Quality assurance is ensured through rigorous testing, adherence to international standards (e.g. ISO 9001) and certifications such as CE marking. High-quality materials and components are used and thoroughly tested before delivery.

What should I consider when buying a mobile concrete batching plant?

Considerations include capacity and output, mobility and flexibility, ease of installation and operation, durability, price and quality assurance. Also, evaluate the supplier's reputation and support services.

How can I ensure optimal performance of my mobile concrete batching plant?

Regular maintenance, proper calibration, training operators, using quality materials and utilising advanced monitoring systems are key strategies to ensure optimal performance. Environmental compliance is also important.

What is the price range of mobile concrete mixing plants in Ukraine?

The price range of mobile concrete batching plants in Ukraine varies depending on capacity and features. Typically, the price range varies from $25,000 to $100,000, depending on capacity and brand.

Who are the top suppliers of Mobile Concrete Batching Plant in Ukraine?

Some of the top suppliers include ZOOMJO GROUP, UkrStroyTech, PromStroyTech and StroyBeton.These suppliers offer a range of products featuring high mobility, energy efficiency and advanced mixing technology.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська