How Does the Concrete Batching Plant Work?

Concrete batching plant is an indispensable equipment on the construction site, which is responsible for mixing raw materials such as cement, sand, stone, water and so on according to a certain proportion to produce concrete that meets the needs of the project. So, how does the concrete mixing plant work? Let's find out below.

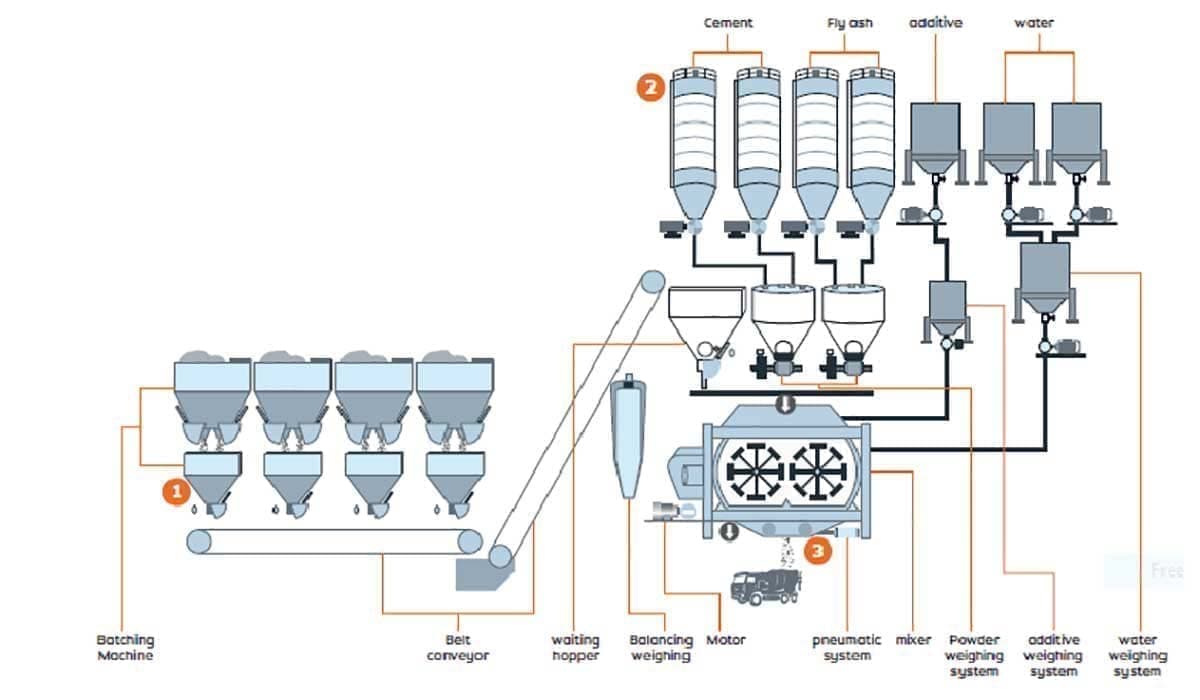

The working principle of concrete batching plant

The workflow of a concrete batching plant can be summarized in the following steps:

Loading system: the loader loads aggregates of different sizes into the mixer. The common ways of aggregate transportation are belt conveyor, bucket elevator.

Batching system: The mixer weighs and batch the powdered materials such as aggregate, cement and fly ash according to the preset ratio.

Mixing system: the mixing materials are mixed in the mixer, and the mixing host (usually adopting twin-shaft or planetary) mixes the raw materials fully to form a uniform, plasticized concrete paste.

Unloading system: the mixed concrete is unloaded from the mixer and loaded into the mixer truck, ready to be transported to the construction site.

Pumping system: Concrete is transported to the area to be poured by pumping equipment.

Cleaning System: After each production run, the plant is thoroughly cleaned to ensure concrete quality and prevent cross contamination between batches.

Key Components of a Concrete Batching Plant

The key components of a concrete batching plant include:

Cement silo: Used to store raw materials such as sand, gravel and cement.

Hopper: Used for measuring and temporary storage of raw materials such as sand, cement and water.

Mixer: Used to mix sand, cement, water and other raw materials into concrete.

Unloading door: used to unload the mixed concrete into the concrete transportation truck.

Conveyor Belt: Used for conveying sand, cement and other raw materials.

Control system: It is used to control the work of various parts of the concrete batching plant.

In addition, modern mixing plant also has automatic control, data acquisition and other intelligent functions, can realize unattended operation, improve production efficiency and quality control level.

How many types of concrete batching plants are there?

According to the installation method, concrete batching plant can be divided into two major types.

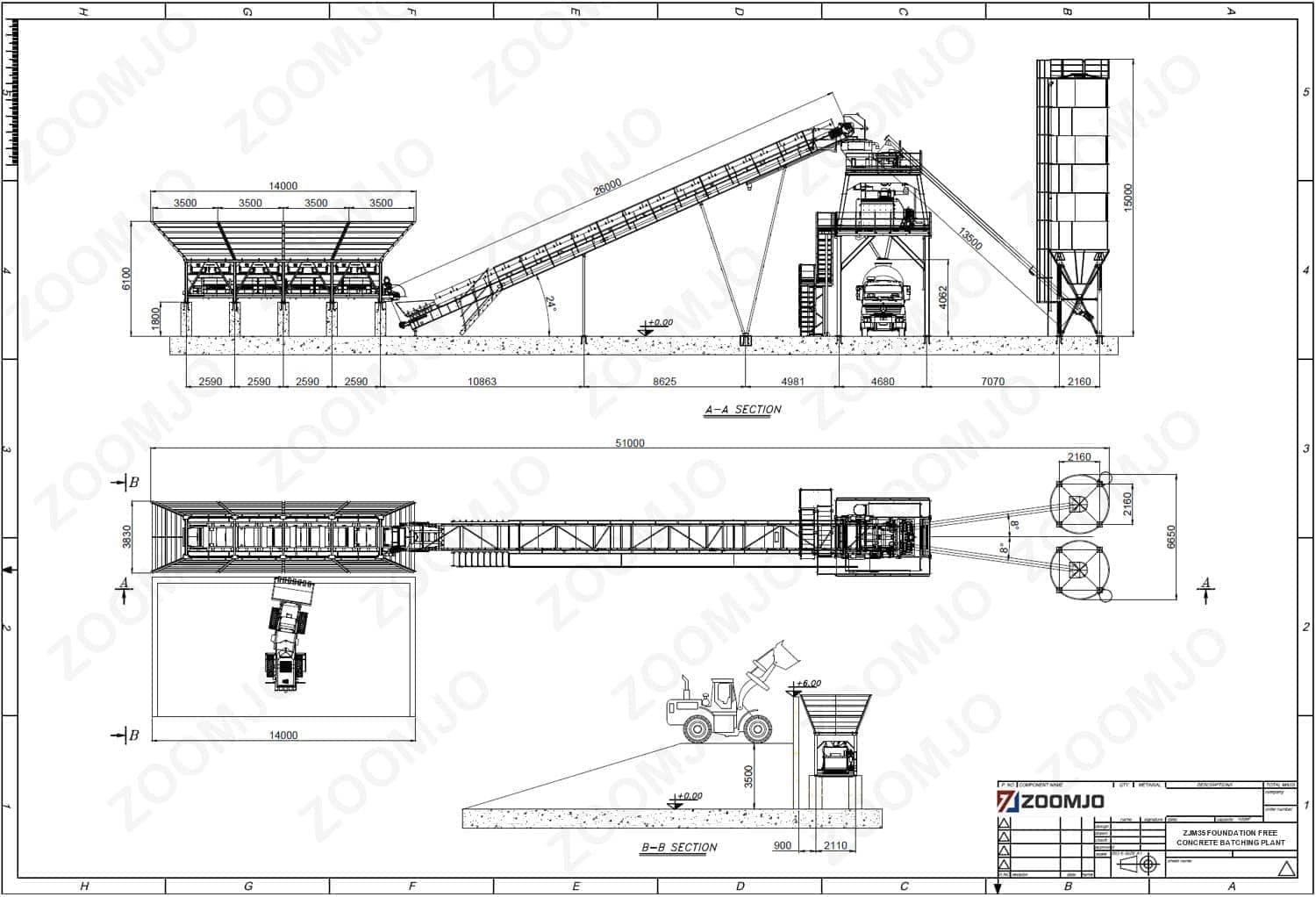

1. Stationary Concrete Batching Plant

This type of mixing plant is installed in a fixed site, suitable for large-scale construction projects. It is characterized by large production capacity, high degree of automation and stable quality of concrete.The common models of ZOOMJO stationary mixing plant are ZJ-35, ZJ-60, ZJ-90, ZJ-120, ZJ-240 and so on.

2. Mobile Concrete Batching Plant

This kind of mixing plant adopts trailer or container design, which can be conveniently moved to different construction sites and is suitable for small and medium-sized projects. It is characterized by strong flexibility, easy installation and small footprint, and the common models of ZOOMJO's mobile mixing plant are ZJY-35, ZJY-60, ZJY-75, ZJY-90, ZJY-120, etc. Whether it is fixed or mobile, ZOOMJO's mobile mixing plant can be used for a wide range of construction sites.

Whether stationary or mobile, ZOOMJO offers a wide range of models to choose from. Different models in terms of production capacity, configuration and automation level are different, users can choose according to the project needs and site conditions, transportation requirements and other actual conditions. So whether you have a large project or a small or medium-sized business, you can find the right concrete batching plant in the ZOOMJO product line.

The workflow of a concrete mixing plant covers the key aspects of raw material preparation, accurate batching, efficient conveying, full mixing and timely discharging. Relying on the intelligent control system and precision weighing equipment, the concrete mixing plant can efficiently produce high-quality concrete that meets the requirements of the project and guarantees the construction progress and quality. It is suitable for the concrete needs of large-scale water conservancy, electric power, bridge and other projects, and is the necessary equipment for modern construction industry.

If you have the demand for concrete batching plant, please feel free to contact us.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська