Stationary Concrete Batching Plant for Sale in Ukraine

Abstract: This article provides an in-depth discussion of the Ukrainian stationary concrete mixing plant market. The article analyzes the market in detail from various perspectives such as market demand, equipment features, selection factors, brands, and maintenance.

Exploring the dynamic landscape of the Ukrainian construction industry

The demand for stationary concrete mixing plants is increasing, and these robust machines are vital for large-scale projects, providing a consistent, high-quality supply of concrete. Whether for highways, bridges or urban development, Ukrainian stationary concrete mixing plants are the cornerstone of modern infrastructure, known for their unmatched efficiency and reliability.

Engineering Design and Precision

Stationary Concrete Batching Plants are precision engineered with advanced control systems and customizable components to meet a variety of project requirements. Investing in these plants increases production capacity, cost-effectiveness and environmental benefits.

Market Dynamics

With the growth of the construction industry in Ukraine, understanding the market dynamics and selecting the right mixing plant is critical to project success and operational excellence.

Introduction to Stationary Concrete Batching Plants

Stationary Concrete Batching Plants are essential tools for the building and construction industry, developed specifically for concrete automation. These plants are ideal for large projects that require a regular supply of concrete over a long period of time. Unlike a mobile concrete batching plant, a stationary batching plant is a high performance and efficient machine.

Function and Design

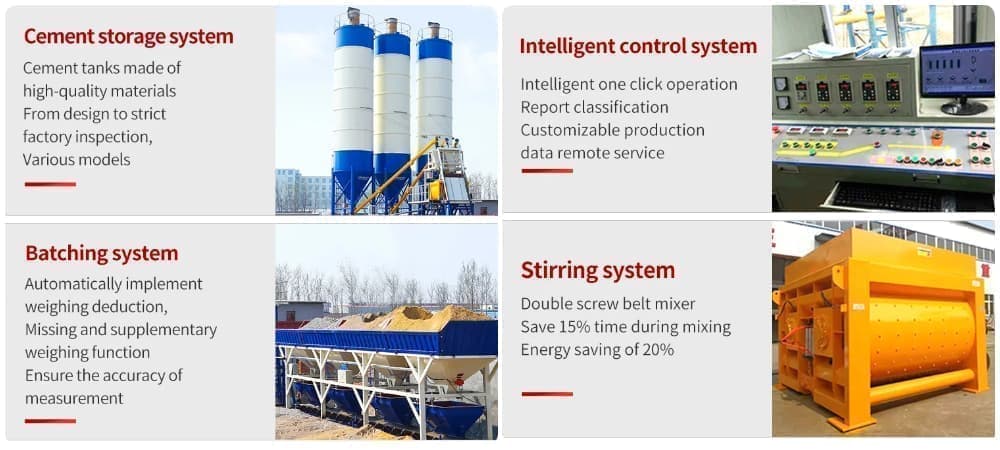

Stationary concrete mixing plants are designed to provide precise control of the concrete production process. They typically consist of the following basic components:

-

Batching system: manipulates and combines basic materials such as cement, water, sand and stockpiles.

-

Combining system: ensures the homogeneous mixing of all elements to produce high grade concrete.

-

Control system: automates the mixing procedure, increasing accuracy and reducing human error.

-

Conveying system: efficiently transports materials between different parts of the plant.

Capacity and output

The plants are available in a variety of capacities, ranging from small plants capable of producing 25 cubic meters per hour to large plants capable of producing 240 cubic meters per hour. The choice of capacity depends on the specific requirements of the job and the expected demand for concrete.

Working principle

The working principle of a concrete batching plant is based on the precise proportioning of materials and an efficient mixing process to ensure the production of homogeneous and high quality concrete.

The workflow usually starts with the batching system, which is responsible for the precise proportioning of basic materials such as cement, water, sand and gravel in preset proportions. These raw materials are first stored in the appropriate silos in the batching plant and then transported through the batching system to the mixing system in predetermined proportions. In the mixing system, these materials are homogeneously mixed to produce concrete that meets specific strength and performance requirements.

The mixing process is managed automatically by a control system that ensures accuracy and minimizes human error. Control systems typically include sophisticated electronics and software that monitor and adjust mixing parameters such as speed, time and material ratios to accommodate different concrete formulations.

Applications

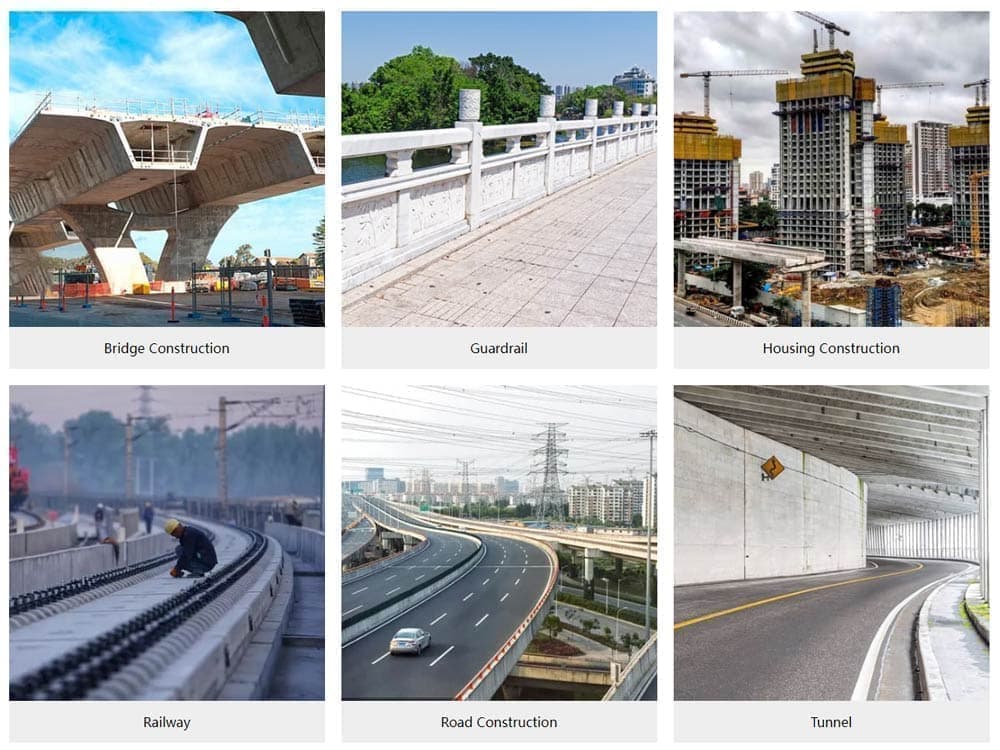

Stationary concrete batching plants are widely used in facility tasks such as highways, bridges, dams and urban development projects. Stationary Concrete Batching Plants are capable of producing large quantities of high quality concrete and are therefore essential for projects where uniformity and reliability are of paramount importance.

In Ukraine, the demand for stationary concrete batching plants is driven by the country's growing infrastructure needs. As the construction industry continues to grow, these plants play a vital role in sustaining the development of modern and durable structures.

Key Features of Stationary Concrete Batching Plants

Important for large-scale construction projects, stationary concrete batching plants offer a range of innovative features that ensure effective and consistent concrete production. Understanding these important features is crucial to making an informed buying choice.

-

High production capacity: one of the outstanding features of stationary concrete mixing plants is their high production capacity. These plants can handle large quantities of concrete, making them ideal for large building and construction projects. The production capacity can vary greatly from one model to another, so buyers can choose a plant according to their needs.

-

Sturdy structural design: The architectural style of the stationary concrete mixing plants is another important feature. These plants are sturdy and durable enough to withstand extreme weather conditions and heavy usage. The sturdy architecture ensures the durability and reliability of the equipment, minimizing downtime and maintenance costs.

-

Advanced control systems: modern stationary concrete mixing plants are equipped with innovative control systems that facilitate specific mixing operations. These systems automate different procedures, improve performance and reduce the possibility of human error. Operators can easily track and adjust mixing standards to achieve the desired concrete quality.

-

Personalized Components: Another important feature is the personalized components to meet the requirements of specific projects. Buyers can choose from a variety of options, including different types of mixers, aggregate storage systems and concrete silos. This customizability ensures that the equipment can meet the specific needs of any construction task.

Energy efficiency

Power performance is an important consideration for stationary concrete mixing equipment. Some modern plants incorporate energy-saving innovations that reduce energy consumption without compromising on efficiency. This not only reduces operating costs, but also meets the goal of ecological sustainability.

Easy maintenance and operation

Reduced maintenance and operation is another important feature of stationary concrete mixing plants. These plants have a user-friendly interface and accessible parts that simplify routine maintenance. This helps ensure that the equipment stays in optimal operating condition and reduces the risk of unexpected breakdowns.

Benefits of Investing in a Stationary Concrete Batching Plant

There are many benefits of purchasing a stationary concrete batching plant that can significantly improve the efficiency and quality of concrete production in building and construction tasks. Below, I will detail a few of the key advantages that make these plants a beneficial financial investment, especially in the Ukrainian market.

-

Increased production capacity: stationary concrete mixing plants can produce large quantities of concrete, making them ideal for large-scale projects. This high production capacity ensures that construction companies stay on schedule without compromising on high quality.

-

Consistent quality: one of the outstanding advantages of stationary mixing plants is their ability to produce consistently high quality concrete. Automated programs and specific control systems ensure the homogeneity of the mixture, which is essential for maintaining the architectural integrity of structures and infrastructure.

-

Cost-effectiveness: While the initial investment in a stationary concrete mixing plant may be high, the long-term cost savings are significant. Reduced labor costs, minimized material losses, and improved energy efficiency all contribute to the overall cost savings.

Environmental Advantages

Modern stationary concrete mixing plants are designed with sustainability in mind. They integrate dirt collection systems and noise reduction innovations that are more environmentally friendly than older plants. This is particularly important in urban areas with strict ecological policies.

Retrofitting and flexibility

Stationary concrete mixing plants can be customized to the specific requirements of the task. Whether it's the type of concrete mixture or the scope of production, stationary batching plants can be tailored to meet different needs, offering a flexibility that mobile batching plants cannot provide.

All in all, a stationary concrete batching plant is an important investment that yields considerable advantages in terms of production capacity, quality, price effectiveness, ecological compliance and personalization. These advantages make stationary concrete mixing plants ideal for construction companies doing business in Ukraine.

Popular Brands and Models in the Ukraine Market

When buying a stationary concrete mixing plant for sale in Ukraine, it is vital to familiarize yourself with the leading brands and designs that control the market. Understanding the options on offer can greatly influence your decision-making process, ensuring that the equipment you choose meets your specific requirements and delivers reliable performance.

Top brands in the Ukrainian market

In the Ukrainian market, a number of well-known brands have emerged in the field of stationary concrete mixing plants, providing high-quality solutions for the local construction industry. Among them, brands such as ZOOMJO GROUP, Ammann, ELKON and Liebherr are favored for their superior technology, durability and efficiency.

The product lines of these leading brands are diverse and capable of meeting the needs of different sizes and types of projects. For example, ZOOMJO's ZJ series of stationary concrete batching plants are known for their compact design and ease of transportation, making them ideal for construction sites where space is limited, while ELKON's ELKOMIX-135 is known for its high level of productivity and automation, which significantly improves work efficiency. And Liebherr's Betomix 3.0 is the preferred choice for large-scale projects thanks to its robust construction and powerful handling capacity.

The ZOOMJO GROUP stationary concrete batching plant is well received in the market as an efficient and professional machine. Its main features include:

-

Compulsory and efficient design: ZOOMJO's concrete batching plant is equipped with JS series twin-shaft forced mixer, which is able to mix concrete quickly and evenly to ensure the quality and consistency of concrete.

-

Fully automated control system: the plant utilizes an advanced electronic control system to achieve fully automated operation, enhancing productivity and stability.

-

Flexible Configuration Options: Various types of mixing plants are available, including stationary, mobile and foundation-free models to suit different construction environments and needs.

Regional manufacturers and their products

In addition to globally recognized brands, there are also a number of regional manufacturers in Ukraine that offer reasonably priced stationary concrete mixing plants. These manufacturers often offer customized solutions that can be adapted to the specific requirements of the Ukrainian market. companies such as UkrStroy and Betonmash are widely recognized for their ability to provide reliable and affordable mixing plants.

UkrStroy's MixMaster-30 is an example of a domestically produced model that combines economy and performance, making it ideal for small to medium-sized construction tasks, while Betonmash's BM-60 is a more noteworthy model that combines effectiveness and speed to meet a wide range of construction needs.

Choosing the right model

Choosing the right design requires consideration of various factors such as production capacity, site issues and budgetary constraints. It is recommended that you speak with an expert to conduct a thorough evaluation of your task requirements to ensure that you spend on equipment that meets your functional goals.

By learning about popular brands and models in Ukraine, you can make an informed decision when purchasing a stationary concrete mixing plant. This knowledge will motivate you to choose a plant that not only meets your needs, but also enhances your building and construction tasks.

Factors to Consider When Buying a Stationary Concrete Batching Plant

When considering the purchase of a stationary concrete mixing plant for sale in Ukraine, there are several key variables that should be scrutinized to ensure that the financial investment meets your functional requirements and financial capabilities. Below, I will list a few important considerations to guide your decision-making process.

-

Production capacity: The production capacity of a concrete mixing plant is an essential factor to consider. It calculates exactly how much concrete can be produced within a specified time frame. Depending on the requirements of the task, you may need a mixing plant with greater or lesser capacity. Analyze the amount of concrete you need to produce on a daily or regular basis and choose the equipment that will effectively meet your needs.

-

Technical specifications: It is important to understand the technical specifications of the equipment. This includes the type of mixer, batching system, control system and other components. Make sure that the technical specifications meet the requirements of your job. For example, the type of mixer (twin shaft, monolithic or pan) can greatly affect the quality and uniformity of the concrete produced.

-

Quality and durability: Purchasing a high-quality, sturdy stationary concrete mixing plant is critical to long-term success. The equipment should be built with durable products and advanced designs to withstand the rigors of continuous operation. Quality control qualifications and service warranties can be a sign of a reliable product.

-

COST AND BUDGET: Cost is a major consideration when purchasing a concrete batching plant. It is important to review the initial purchase rate, installment costs and possible operating costs. It is advisable to compare different models and brands to find the one that best fits the budget plan without compromising on high quality and performance.

-

Vendor reputation and support: the online reputation of the distributor is an important consideration. Respectable distributors not only offer high-grade tools, but also provide excellent after-sales service, including repair services and additional parts availability. Research customer reviews and ratings to determine the reliability of the supplier.

Factors to consider include production capacity, technical specifications, quality and durability, cost and budget, supplier reputation and ecological considerations.

Ecological factors are becoming increasingly important in today's building and construction market. One should look for plants that offer green features such as dirt collection systems and energy-efficient operations. In addition, compliance with nearby environmental guidelines needs to be verified.

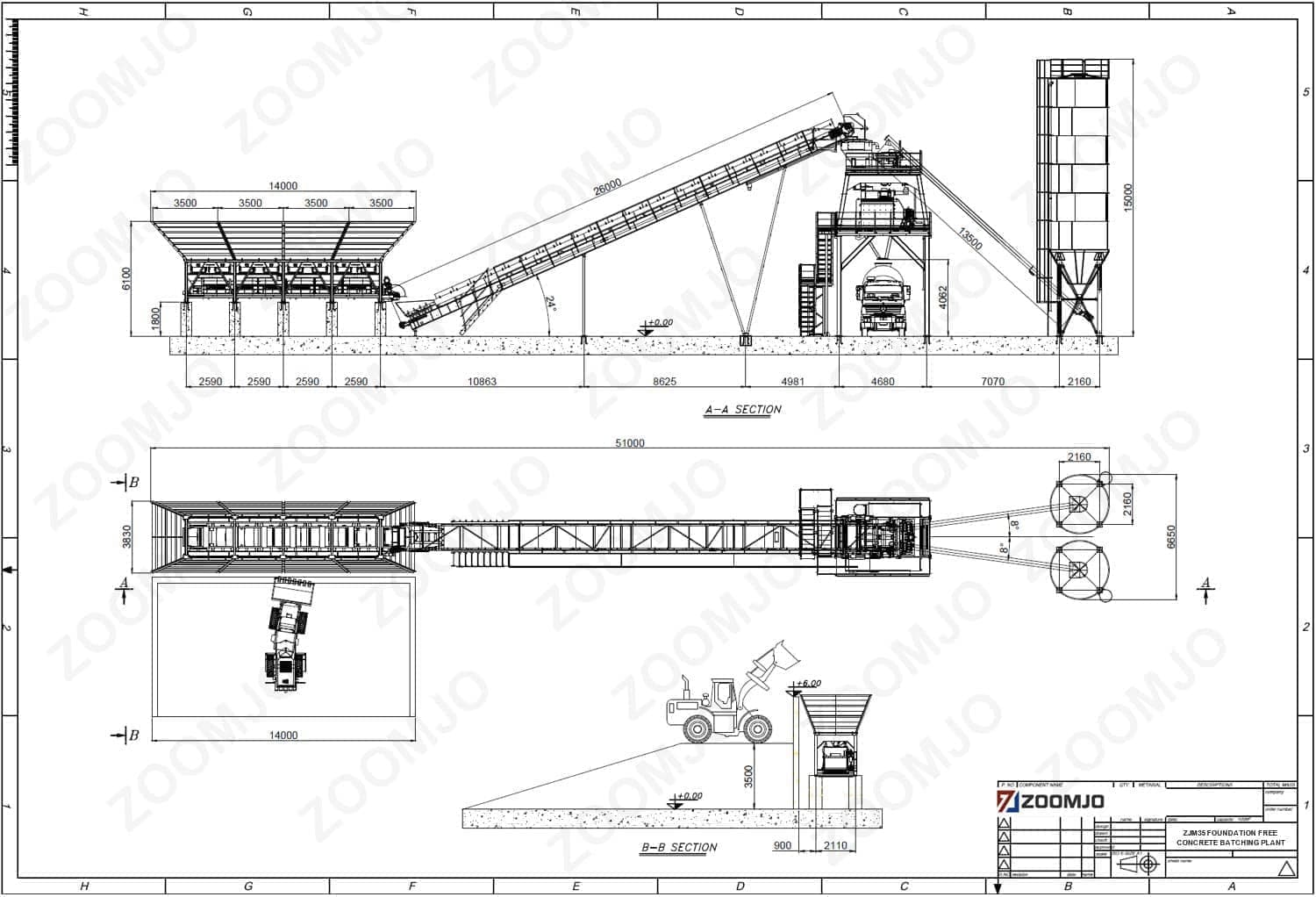

Area and space requirements

Finally, consider the location and area required to install the plant. Ensure that there is enough space to accommodate the plant and associated infrastructure, such as the location of storage space for resources and finished products. Access for transportation vehicles also needs to be considered.

Cost analysis and pricing trends in Ukraine

Understanding price dynamics and pricing trends is crucial when considering the purchase of a stationary concrete mixing plant in Ukraine. The market for these plants is affected by different factors such as technological developments, changing demand and economic issues. In Ukraine, the construction industry is experiencing a steady growth trajectory, which has a direct impact on the price of concrete mixing plants.

Factors affecting costs

The cost of a stationary concrete batching plant depends largely on its production capacity, level of automation, brand reputation, and detailed attributes offered. Larger plants with higher production capacity tend to have a higher first-time price, but may offer better economics in the long run. There is also a premium for plants equipped with advanced automation systems that increase efficiency and minimize labor costs.

Price trends in Ukraine

Recently, there has been a slight increase in the price of stationary concrete mixing plants in Ukraine. This pattern can be attributed to the escalating demand for frame upgrades and the adoption of more advanced technologies. Nonetheless, prices in the market remain affordable, with different suppliers offering a range of alternative products to meet different spending plans and task requirements.

Cost-benefit analysis

Buying a stationary concrete batching plant requires a thorough cost-benefit assessment. While the upfront capital investment may seem significant, advantages such as improved production performance, reduced product waste and improved product quality can justify the outlay in the long run. It is vital to compare these advantages with the outlay and make an informed choice.

Financing and leasing options

For businesses concerned about upfront pricing, Ukraine offers a variety of financing and leasing options. These options can ease the financial burden on businesses by paying in installments, enabling them to purchase quality stationary concrete mixing plants without compromising financial security.

Tips for Maintenance and Service Life of Concrete Batching Plants

Ensuring the longevity and desired performance of a stationary concrete mixing plant requires a comprehensive maintenance strategy. Normal maintenance not only improves performance, but also reduces unplanned downtime and repair costs. Here, I will outline some essential maintenance ideas to help extend the life of your concrete mixing plant.

Regular Inspections and Cleaning

Performing routine inspections is critical to identify wear and tear early on. Perform routine inspections on all components of the mixer, conveyor belt and control system. Clean the equipment after each use to prevent concrete deposits from building up, causing blockages and compromising efficiency. Pay special attention to mixer drums and blades, as they are prone to concrete buildup.

Lubrication of Moving Parts

Proper lubrication of all moving parts is essential to minimize friction and prevent wear and tear. Make sure bearings, equipment and other mechanical parts are properly lubricated according to the manufacturer's recommendations. Proper lubrication not only extends the life of these parts, but also ensures that the program runs smoothly.

Calibration and Adjustment

Routine calibration of the weighing system ensures that the plant produces concrete with accurate mix proportions. Changes may also be required to maintain the accuracy of the batching system. Incorrect calibration can result in lower quality concrete and higher material costs.

Monitor and Replace Worn Parts

Check all parts for signs of wear, including belts, seals and electrical components. Replacing wear parts in a timely manner prevents further damage and ensures safety. Maintaining an inventory of additional parts as necessary reduces downtime during replacement.

Specialized Maintenance

Schedule normal professional maintenance with a licensed professional familiar with stationary concrete mixing plants. Expert inspections can reveal problems that may not be detected during routine inspections, providing added security for your financial investment.

| Maintenance Task | Frequency | Required Action |

|---|---|---|

| Inspection and Cleaning | Daily | Check for residue accumulation and clean thoroughly. |

| Lubrication | Weekly | Lubricate all moving parts according to guidelines. |

| Monthly Calibration | Monthly | Adjust the weighing and batching systems. |

| Component Replacement | As Needed | Replace used or damaged components. |

| Biannual Professional Maintenance | Semi-Annually | Have a certified expert conduct a thorough inspection. |

Adhering to these maintenance measures will ensure that your stationary concrete batching plant will continue to be trustworthy and reliable, thus inevitably contributing to the success of your construction project.

Where can I find stationary concrete batching plants in Ukraine?

There are several avenues to explore when looking for stationary concrete batching plants for sale in Ukraine. Understanding the regional market and knowing where to look can greatly improve your buying experience. Below, I've listed the key resources and platforms where you can find these important pieces of construction equipment.

Local manufacturers and dealers

One of the most reliable ways to buy a stationary concrete mixing plant in Ukraine is through local manufacturers and dealers. These companies typically offer a wide range of designs and can provide important insights into the best options for your detailed needs. Additionally, there may be advantages to buying in your area, such as easier access to additional components and maintenance services.

Online Marketplaces

Another effective method is to check out online industries that specialize in industrial and construction tools.Internet sites such as OLX Ukraine and Prom.ua list a range of new and used concrete mixing plants. These systems allow you to compare costs, specifications and supplier rankings to help you make an informed decision.

Exhibitions and fairs

Attending specialized exhibitions and shows that focus on construction and commercial machinery is also a great way to find a stationary concrete mixing plant. These events often include the latest models and technology and provide opportunities to network with market experts and suppliers.

Market publications and magazines

Industry-specific magazines often carry promotional information for concrete mixing plant suppliers and representatives. These sources of information are an excellent way to discover new models and technologies in the field, as well as supplier contact details.

Networking with industry professionals

Networking within the construction industry can provide advice and insights for discovering quality stationary concrete batching plants. Engaging with peers and participating in market events can provide leads to reliable suppliers and unique special offers.

| Source | Advantages |

|---|---|

| Local Manufacturers | Access to spare parts, local assistance |

| Online Marketplaces | Wide selection, clear price comparison |

| Trade Shows | Latest versions, networking opportunities |

| Industry Publications | Promotional activities, contact information |

| Professional Networks | Advice, special offers |

By considering these resources, you can effectively navigate the Ukrainian fixed concrete batching plant market to ensure that you find items that meet your needs and spending plans.

Frequently Asked Questions about Stationary Concrete Batching Plants for Sale in Ukraine

What is a stationary concrete batching plant?

A stationary concrete batching plant is a non-mobile concrete production plant for large construction projects that require a steady, high-quality supply of concrete.

Why choose a Stationary Concrete Batching Plant over a Mobile Batching Plant?

Stationary batching plants offer superior performance and efficiency for long-term projects. Designed for high capacity and consistent quality, stationary concrete batching plants are suitable for large-scale infrastructure construction.

What factors should I consider when buying a stationary concrete batching plant in Ukraine?

Key factors include production capacity, technical specifications, quality and durability, cost and budget, supplier reputation, and environmental factors. It is important to combine these factors with your project needs and financial capabilities.

What are the benefits of investing in a stationary concrete batching plant?

Investing in a stationary concrete batching plant offers increased production capacity, quality consistency, cost-effectiveness, environmental benefits and customization options, making it a strategic investment for construction companies.

Which brands and models are popular in Ukraine?

Popular brands include Ammann, ELKON and Liebherr. Well-known models such as Ammann's CBT 60 SL Elba, ELKON's ELKOMIX-135 and Liebherr's Betomix 3.0 are favored for their robust design and high productivity.

Where can I find stationary concrete mixing plants for sale in Ukraine?

You can find the right stationary concrete mixing plant through local manufacturers and dealers, online marketplaces such as OLX Ukraine, trade shows, industry publications and specialized networks.

What are the maintenance tips to ensure the longevity of a concrete batching plant?

Regular inspections and cleaning, proper lubrication, calibration, monitoring and replacement of wear parts, and professional service are critical to maintaining the efficiency and longevity of your mixing plant.

How do price trends affect the purchase of concrete batching plants in Ukraine?

Price trends are influenced by demand, technological advances and economic conditions. Understanding these trends will help you make an informed decision about the cost and investment in a stationary concrete batching plant.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська