Stationary Concrete Batching Plant Specifications & Models

Stationary concrete mixing plant is an indispensable equipment in modern construction projects, which is widely used in construction projects of various scales with its high efficiency and stability. In this article, we will take an in-depth look at the key specifications of stationary concrete mixing plants and provide a practical guide to purchasing and maintenance.

The meaning of batching plant specifications

The specifications of a stationary concrete mixing plant usually refer to its hourly theoretical production capacity, which is the amount of concrete cubes that the plant can produce per hour under ideal conditions. The specifications of a concrete mixing plant can also be categorized based on a number of parameters such as its mixer type, aggregate bin volume, aggregate lifting method, and so on.

Common Specification Models

The models of stationary concrete mixing plant mainly include HZS, HSR, HLS, etc. These models of mixing plant are suitable for construction projects that need to produce concrete in large quantities, and the common specifications of stationary concrete mixing plant on the market at present are: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240 and so on.

-

HZS25: It means that the hourly theoretical production capacity of the mixing plant is 25 cubic meters.

-

HZS120: It means the hourly theoretical production capacity of the mixing plant is 120 cubic meters.

These numbers indicate the theoretical maximum production capacity of the mixing plant per hour, and the larger the number, the larger the production capacity.

Note: There is a certain difference between the theoretical production capacity and the actual production capacity, and the influencing factors include the nature of materials, ambient temperature, wear and tear of the equipment, etc.

Besides production capacity, different specifications of the mixing plant will also have differences in the following aspects.

1. Mixer type

Forced mixer: common models such as JS500, JS750, JS1000, JS1500, JS2000, etc. It is suitable for various types of concrete, especially dry and hard concrete.

Self-falling mixer: It is suitable for concrete with better fluidity, but less application.

2. Aggregate bin volume

Small capacity silo: applicable to small mixing plant, the total capacity of aggregate silo is generally below 30m³.

Medium capacity silo: applicable to medium-sized mixing plant, the total capacity of aggregate silo is generally between 30m³ and 100m³.

Large-capacity silo: applicable to large-scale mixing plant, the total capacity of aggregate silo is generally more than 100m³.

3. Aggregate lifting method

Elevating bucket: applicable to small and part of medium-sized mixing plant, small footprint, compact structure.

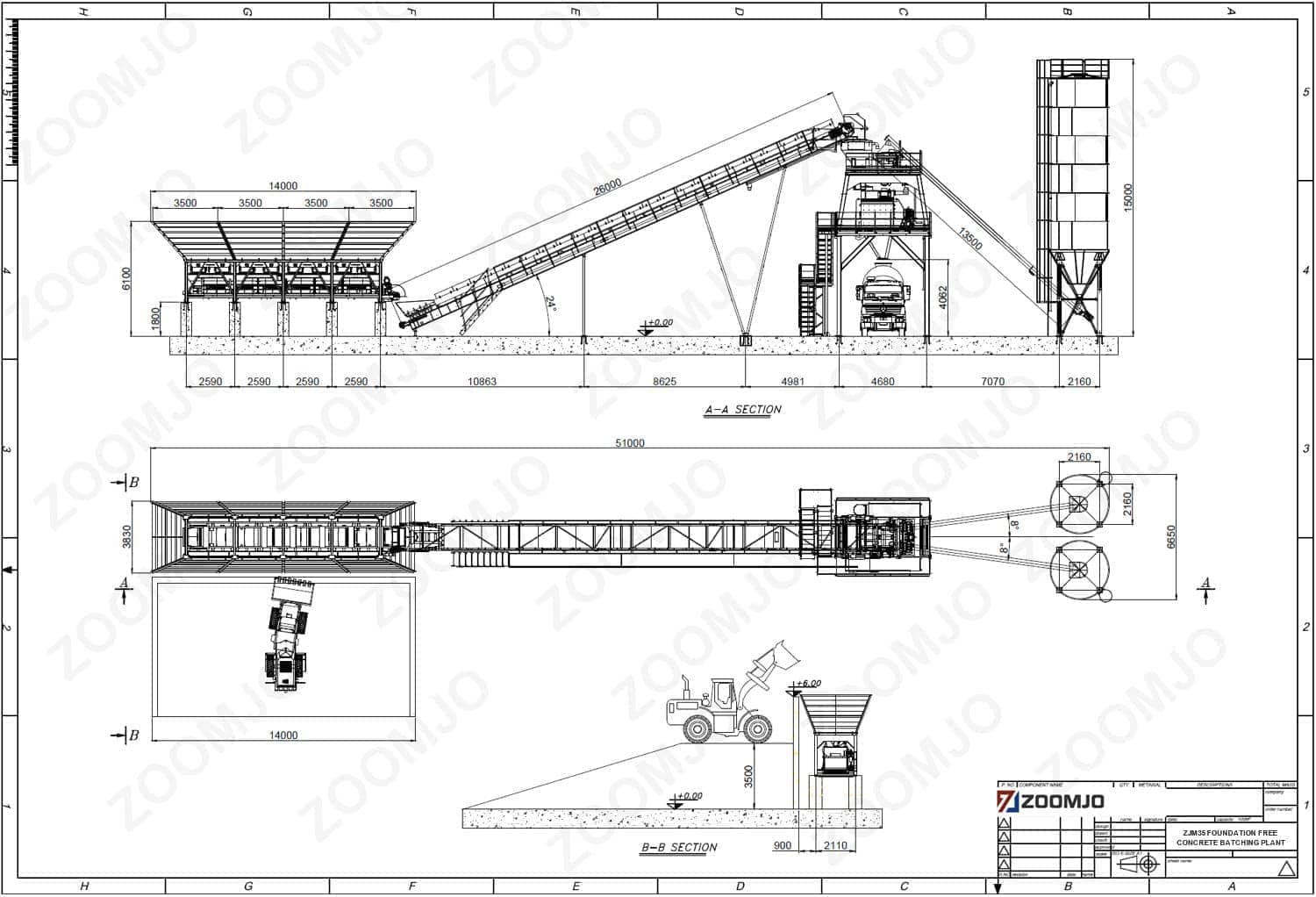

Belt conveyor: applicable to medium and large-scale mixing plant, high conveying efficiency, but covers a large area.

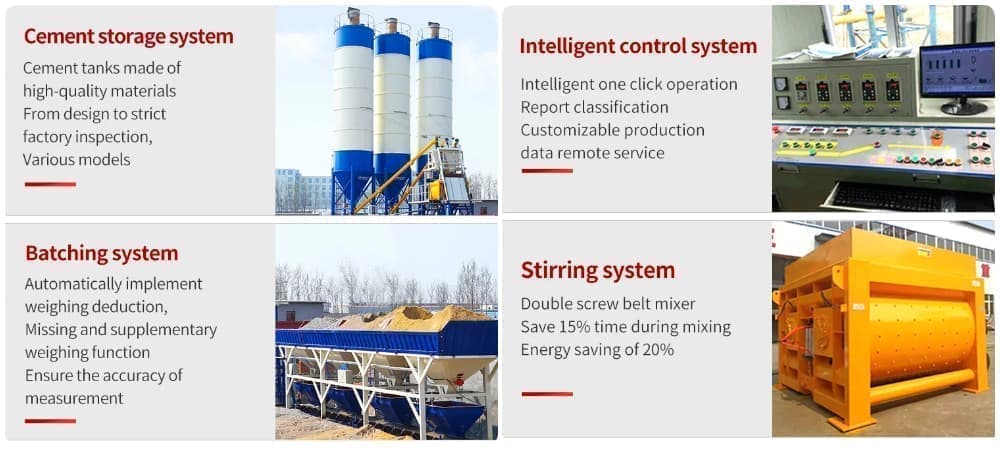

4. Control system

Manual control: applicable to early or less economical mixing plant.

Semi-automatic control: there is a certain degree of automation, but still requires manual intervention.

Full-automatic control: adopting PLC automatic control system, with high production efficiency and small error, applicable to modernized large-scale mixing plant.

5. Other accessories

Cement silo: usually 100 tons to 500 tons of storage capacity, according to the actual needs of the configuration.

Admixture adding system: used to add admixtures to improve the performance of concrete.

Dust removal system: used to control dust and meet the requirements of environmental protection.

When choosing a stationary concrete mixing plant, you need to consider comprehensively according to the project demand, budget, construction site and other factors.

Factors affecting the selection of mixing plant specifications

To choose the right mixing plant specifications, the following factors need to be considered:

Scale of the project: if the project is large and the demand for concrete is high, then the mixing plant with larger production capacity needs to be selected.

Types of concrete: Different types of concrete with different ratios and production processes will also affect the choice of mixing plant.

Site conditions: the footprint of the mixing plant, foundation bearing capacity, etc., will limit the selection of the mixing plant.

Budget: different specifications of the mixing plant, its price is different, you need to choose according to the budget.

Suggestions for selection of mixing plant specifications

Small-scale projects: HZS25, HZS35 and other small-scale mixing plant can meet the demand.

Medium-sized projects: HZS50, HZS60 and other medium-sized mixing plant is more suitable.

Large-scale projects: HZS90, HZS120 and other large-scale mixing plant can improve work efficiency.

The selection of mixing plant is a professional work, it is recommended to consult professional concrete mixing plant manufacturers.

Maintenance

In order to ensure the long-term stable operation of stationary concrete mixing plant, the following maintenance should be carried out regularly:

-

Cleaning: Clean the mixer and batching system regularly to prevent material residue.

-

Inspection: Check the wear and fasteners of the equipment and replace the damaged parts in time.

-

Lubrication: Regularly lubricate the moving parts according to the manufacturer's recommendations.

ZOOMJO: 30 years of concrete mixing plant expertise

ZOOMJO is a concrete mixing plant manufacturer with 30 years of experience, specializing in customized complete solutions for the ready-mixed concrete and precast industries. Our products cover a wide range of models from small mobile to large stationary concrete mixing plants, designed to meet the stringent requirements of concrete production efficiency and quality for projects of different sizes.

ZOOMJO Product Advantages

Diverse models and flexible configurations

Our product line covers a wide range of models that can be customized according to customers' specific needs, including:

-

Small mobile mixing plant: Suitable for on-site use, flexible and easy to install.

-

Large stationary mixing plant: high capacity, high degree of automation, suitable for large-scale projects.

Excellent quality and durability

ZOOMJO always adheres to the high quality standard and adopts advanced manufacturing technology and high quality raw materials to ensure the reliable performance and long service life of each machine.

Professional service, attentive support

We provide perfect pre-sales consulting, installation and commissioning, technical training and after-sales service, to provide customers with a full range of support.

Cost-effective, fast return on investment

ZOOMJO's products have a very high cost-effective ratio while guaranteeing the quality, which can help customers to reduce production costs and increase the return on investment.

Price range

The price of a small concrete mixing plant typically ranges from US$8,000 to US$30,000, while the price of a large mixing plant varies depending on the configuration and model, and can reach up to hundreds of thousands of dollars.

About ZOOMJO Stationary Concrete Batching Plant Specifications and Models

| Model | HZS / ZJ25 | HZS / ZJ35 | HZS / ZJ50 | HZS / ZJ60 | HZS / ZJ75 | HZS / ZJ90 | HZS / ZJ120 | HZS / ZJ180 | HZS / ZJ240 |

| Productivity | 25m³/h | 35m³/h | 50m³/h | 60m³/h | 75m³/h | 90m³/h | 120m³/h | 180m³/h | 240m³/h |

| Concrete mixer | JS 500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | JS2000 | JS3000 | JS4000 |

| Mixer discharging capacity | 0.5m³ | 0.75m³ | 1m³ | 1m³ | 1.5m³ | 1.5m³ | 2m³ | 3m³ | 4m³ |

| Feeding Mode | Lift Hopper | Lift Hopper | Lift Hopper | Belt Conveyor | Lift Hopper | Belt Conveyor | Belt Conveyor | Belt Conveyor | Belt Conveyor |

| Aggregate batching machine | PLD800 | PLD1000 | PLD1600 | PLD1600 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Kinds of aggregate | 2/3/4 | 2/3/4 | 3/4 | 3/4/5 | 3/4 | 3/4/5 | 3/4/5 | 3/4/5 | 3/4/5 |

| Max aggregate size | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm | 80/100mm |

| Discharging height | 3.8m | 4.1m | 4.1m | 4.1m | 4.1m | 4.1m | 4.3m | 4.3m | 4.3m |

| Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement weighting accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| weight | 10t | 13.5t | 18.5t | 28t | 25t | 40t | 65t | 88t | 98t |

| General installed power | ≈65kw | ≈75kw | ≈100kw | ≈110kw | ≈140kw | ≈160kw | ≈220kw | ≈290kw | ≈340kw |

If you are interested in ZOOMJO products, welcome to visit our official website or contact our sales representatives, we will be happy to serve you.

-

If you have more specific questions, for example:

-

What is the size of your project?

-

What types of concrete do you need to produce?

-

What are your site conditions?

-

What is your budget range?

You are welcome to provide more information and we will provide you with more detailed suggestions.

Fixed Concrete Batching Plant FAQs

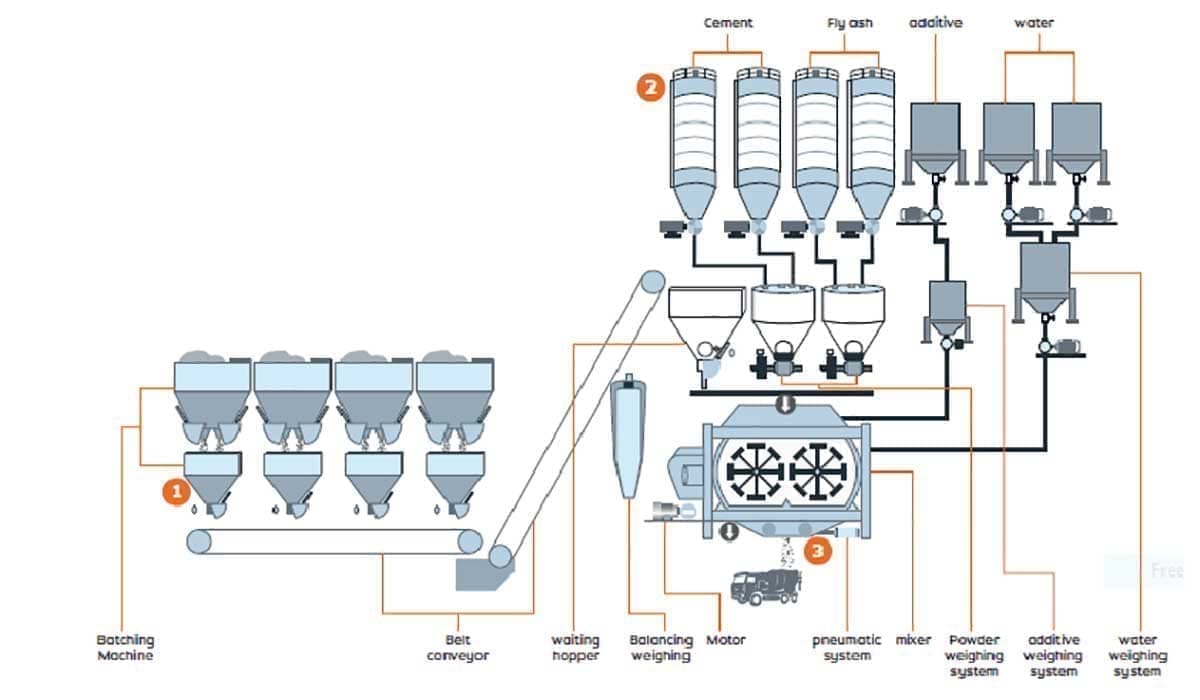

Basic components of a batching plant

-

Batching System: Responsible for the accurate weighing of raw materials such as cement, aggregate, water, etc. to ensure accurate concrete proportioning.

-

Mixing system: Mix the weighed raw materials in the mixer to form uniform concrete.

-

Conveying system: Convey the concrete to the mixer truck or construction site through belt conveyor, screw conveyor and other equipment.

-

Control system: including PLC, touch screen, etc., to realize the automatic control of the whole mixing process and improve the production efficiency.

Advantages of stationary concrete mixing plant

-

High production efficiency: Suitable for large-scale construction projects, capable of producing large quantities of concrete quickly.

-

Stable concrete quality: Precise batching system and automatic control ensure the uniform quality of concrete.

-

Easy to operate: High degree of automation, operators only need to carry out simple settings and monitoring.

-

Widely used: Widely used in residential, commercial buildings, infrastructure and other types of projects.

Working principle of stationary concrete mixing plant

-

Batching: According to the project design requirements, the control system sends commands to the batching system, and each silo weighs out the required raw materials proportionally.

-

Mixing: The weighed raw materials enter into the mixer through the conveying system, and under the strong mixing of the twin-shaft concrete mixer, all kinds of materials are fully mixed to form uniform concrete.

-

Discharge: The mixed concrete is transported to the mixer truck or transfer pump through the discharge port and delivered to the construction site.

The difference between stationary mixing plant and mobile mixing plant?

Fixed mixing plant has large production capacity and better configuration, which is suitable for large-scale projects; mobile mixing plant has high flexibility, which is suitable for projects with small construction sites or frequent changes.

How to choose the right mixing plant?

When choosing a mixing plant, you should consider the scale of the project, the type of concrete, site conditions and other factors, and choose the suitable model and configuration after comprehensive evaluation.

What should I pay attention to the maintenance of the mixing plant?

Regularly check the lubricating oil, replace the wearing parts, and clean the internal debris of the equipment to ensure the normal operation of the equipment.

Conclusion

Stationary concrete mixing plant is the key equipment to realize efficient and stable concrete production. By choosing the right specifications and performing proper maintenance, its performance can be maximized to meet the needs of various construction projects. We hope this article can provide you with valuable reference and guidance.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська