What are concrete batching plant ready mix machines?

Ready-mix concrete mixing plant, also known as concrete batching plant or concrete mixing plant, is an indispensable key equipment in modern construction projects. It does not simply refer to a mixer, but a whole set of integrated system for producing ready-mixed concrete. In this article, from the perspective of a professional mixing plant manufacturer, we will explain in depth what a ready-mixed concrete mixing plant is, and elaborate its composition, working principle, application and selection points.

First, the definition and composition of ready-mixed concrete mixing plant

Ready-mixed concrete mixing plant refers to the cement, aggregate (sand, stone), water, and according to the need to mix additives, mineral admixtures and other components, in accordance with a predetermined proportion of measurement, mixing, production of concrete mix, and through the concrete mixing trucks transported to the construction site of the complete set of equipment.

A complete ready-mixed concrete mixing plant usually contains the following main components:

-

Mixing machine (mixer): This is the core component of the mixing plant, responsible for mixing various materials evenly into concrete. Common types of mixers are forced mixer (such as JS series double horizontal shaft forced mixer), drum mixer, disc mixer and so on. Among them, JS series double horizontal shaft forced mixer is most widely used in ready-mixed concrete plant for its advantages of high mixing efficiency, good mixing quality and strong applicability.

-

Batching system: It includes aggregate batching machine, cement silo, powder silo, water metering system, admixture metering system, etc., which is responsible for accurate metering of various raw materials.

-

Conveying system: including aggregate conveyor (such as belt conveyor), cement conveyor (such as screw conveyor), water pump, admixture pump, etc., is responsible for conveying all kinds of materials to the mixing machine.

-

Control system: computer control is adopted to realise the automatic operation of the mixing plant, including batching control, mixing control, unloading control, etc., and data recording and report generation are also available.

-

Storage system: including aggregate silo, cement silo, powder silo, water tank, admixture storage tank, etc., used for storing various raw materials.

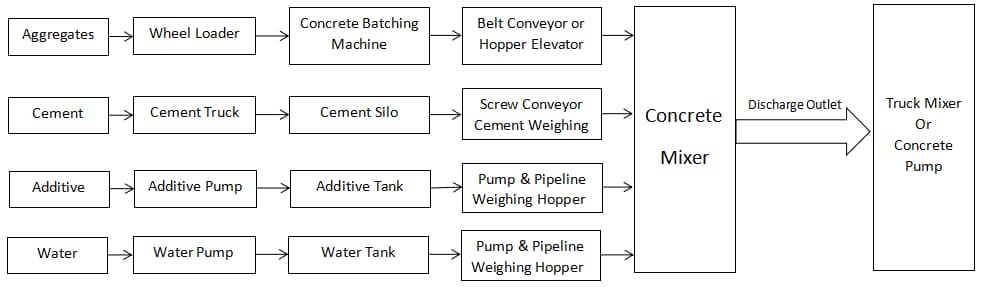

Second, the working principle of ready mix concrete mixing plant

The workflow of ready-mixed concrete mixing plant mainly includes the following steps:

-

Storage: Raw materials such as cement, aggregates, water and admixtures are stored in their respective storage systems.

-

Loading: The various raw materials are transported to the batching machine or metering device by means of a conveying system.

-

Batching: Accurate dosing of various raw materials through the batching system according to the preset concrete ratio.

-

Mixing: Put the measured raw materials into the mixing machine and mix them thoroughly to form a uniform concrete mixture.

-

Unloading: Unload the mixed concrete into the concrete mixer truck.

-

Transport: The concrete mixing truck will transport the concrete to the construction site.

Third, the classification and selection of ready-mixed concrete mixing plant

Types of ready-mixed concrete mixing plant

According to the project requirements, ready-mixed concrete mixing plant is mainly divided into two types: mobile and fixed. They have their own characteristics and are suitable for different construction scenarios.

Mobile ready-mixed concrete mixing plant

Mobile ready-mixed concrete mixing plant adopts modular design, integrating batching, mixing and conveying systems into one or more movable units. This design makes it very easy to install and dismantle, and it can quickly adapt to the changing construction environment of roads, bridges and other projects, especially suitable for projects that require frequent transfer.

The market availability of mobile concrete batching plants ranges roughly from 25 to 90 cubic metres per hour. In terms of price, the range for a small mobile batching plant (25-50 cubic metres per hour) is around US$38,000 to US$70,000; and for a medium mobile batching plant (60-90 cubic metres per hour), between US$70,000 and US$120,000. Please note that the above prices are for reference only and the final price depends on the specific configuration and market fluctuation.

Features:

-

High mobility: modular design, easy to dismantle, transport and install, can be quickly transferred to the construction site.

-

Small footprint: Compact structure, requires a small site, and is highly adaptable.

-

Short installation cycle: fast installation and commissioning, can be quickly put into use.

-

Relatively low investment cost: compared with the same size of the fixed mixing plant, the initial investment is less.

Stationary ready-mixed concrete mixing plant

A stationary ready-mixed concrete mixing plant is a plant installed at a fixed site for long-term, large-scale concrete production. It is designed for projects that require a continuous and stable supply of large quantities of concrete, such as large commercial complexes, water conservancy pivot projects (e.g. dams, hydroelectric power stations), large bridges, high-speed railways, and precast component factories. Once installed, a stationary mixing plant operates continuously at a fixed location to meet long-term, high-strength concrete demand.

Features:

-

Large production capacity: It can be equipped with larger capacity mixing mainframe and better supporting equipment to meet the demand for large volume concrete.

-

High degree of automation: more advanced control system is usually adopted to achieve automatic and intelligent production.

-

High precision of dosing: High precision of dosing system ensures the stability and consistency of concrete quality.

-

Good operational stability: the equipment runs stably and reliably, with a low failure rate.

Common types of stationary ready-mixed concrete mixing plant:

Fixed mixing plant is mainly divided into the following types according to its feeding method and structural form:

-

Belt Conveyor Mixing Plant: Aggregate is conveyed to the batching machine through belt conveyor, which has the advantages of high production efficiency, good continuity, high metering precision, etc. It is suitable for large and medium-sized projects, and is the most widely used type at present. For example, HZS60, HZS90, HZS120, HZS180, etc. The figures represent the theoretical production capacity (cubic metre/hour).

-

Bucket elevating mixing plant: Aggregate is vertically elevated to the batching plant through elevating hopper, with relatively simple structure and small footprint, suitable for small and medium-sized projects or projects with limited space. For example, HZS25, HZS35, HZS50 and other models.

Generally speaking, the price range of small fixed station (such as HZS25, HZS35, 25-35 cubic metres per hour) is around $40,000 to $80,000; the price range of medium-sized fixed station (such as HZS50, HZS60, HZS75, 50-60 cubic metres per hour) is around $100,000 to $158,000; the price range of large fixed station (such as HZS90, HZS120, HZS180, 90-180 cubic metres per hour and above) have a price range of US$180,000 to US$300,000 or even higher. It should be emphasised that this is only a rough reference range, and the actual price needs to be determined according to the specific models, configurations, market conditions and suppliers' quotations.

Factors affecting the price of stationary mixing plant

The price of a stationary mixing plant is affected by a number of factors, including:

-

Production capacity: The larger the production capacity, the higher the required equipment configuration and the higher the price.

-

Configuration level: The brand and performance of core components such as mixing machine, batching machine, control system, and whether it is equipped with environmental protection equipment (such as dust collector, waste water treatment system) will affect the price.

-

Level of automation: the higher the degree of automation, the more advanced the control system, the higher the price.

Stationary Concrete Batching Plant VS Mobile Concrete Batching Plant

| Characteristics | Mobile Batching Plant | Stationary Batching Plant |

|---|---|---|

| Mobility | Strong, easy to transfer | Weak, fixed installation |

| Production capacity | Relatively small | Large |

| Degree of automation | Relatively low | High |

| Investment cost | Lower | Higher |

| Applicable Scenarios | Short construction period, frequent transfer, site constraints, temporary works | Large-scale, long-term, large-volume, high-quality requirements of the project |

Selection points of ready-mixed concrete mixing plant

When choosing a ready-mixed concrete mixing plant, the following factors need to be considered:

-

The scale of the project and the amount of concrete used: Select the appropriate model and production capacity of the mixing plant according to the scale of the project and the amount of concrete used.

-

Conditions of the construction site: Select the appropriate type of mixing plant and layout according to the space and traffic conditions of the construction site.

-

Concrete quality requirements: according to the project on the strength of concrete, ease of concrete and other quality requirements to choose the appropriate mixing host and batching system.

-

Investment budget: according to the investment budget to choose the appropriate cost-effective mixing plant equipment.

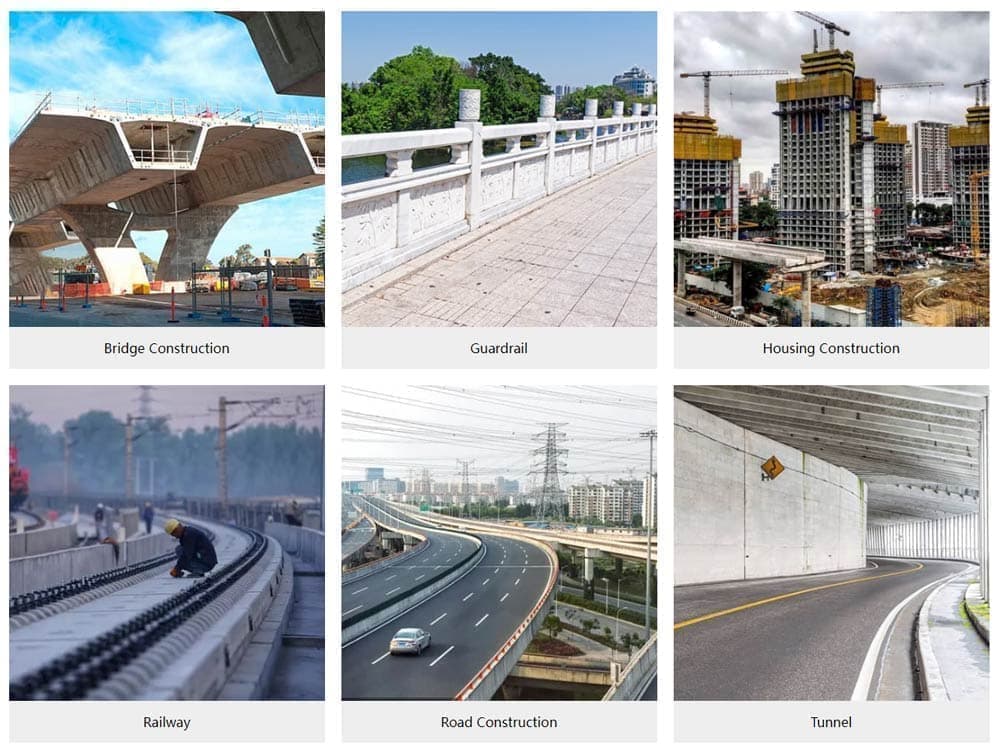

Application of Ready Mix Concrete Batching Plant

Ready mix concrete mixing plant is widely used in various construction projects, including:

-

Infrastructure construction: such as roads, railways, bridges, tunnels and airports.

-

Commercial buildings: such as shopping centres, schools, hospitals, etc.

-

Water projects: e.g. dams, reservoirs and canals.

-

Nuclear power projects: for making radiation resistant concrete.

-

Mine filling: used for the production of concrete for mine filling.

Global Case for Ready Mix Concrete Batching Plants

ZOOMJO, as a leading global manufacturer of ready-mixed concrete plants, has achieved remarkable success with its plants being widely used in many regions such as Europe, Central Asia, Africa and Southeast Asia.

Central Asia: Kazakhstan ZJ-75 ready-mixed concrete mixing plant installation case

ZOOMJO's ZJ-75 ready-mixed concrete mixing plant was selected as the main equipment for a large commercial complex project in Kazakhstan. Located in the capital city of Nursultan, the project has strict requirements for concrete supply capacity and environmental performance.

-

Features: The ZJ-75 ready-mix plant adopts an environmentally friendly design, which reduces dust and noise pollution and complies with local environmental regulations. Meanwhile, the plant's efficient mixing capacity ensures the uniformity and strength of the concrete.

-

Installation and commissioning: ZOOMJO's technical team overcame the challenges of the harsh local climate and successfully completed the installation and commissioning of the plant. The freeze-proof design of the plant ensures stable operation in low temperatures.

Africa: ZJ-50 Ready Mix Concrete Batching Plant Installation in Nigeria

ZOOMJO's ZJ-50 ready-mixed concrete mixing plant was selected as the key equipment for a large housing development project in Nigeria. The project is located in Lagos and aims to provide high quality housing for the local population.

-

Features of the plant: The ZJ-50 ready-mix plant is ideal for use in urban environments due to its compact design and efficient mixing capacity. The plant's automated control system ensures accurate proportioning and efficient production of concrete.

-

Installation and commissioning: ZOOMJO's technical team completed the installation and commissioning of the plant in a short period of time and provided detailed operator training to ensure that the customer was proficient in the use of the plant.

Example of ZJ-60 ready-mixed concrete mixing plant in Vietnam

ZOOMJO's ZJ-60 ready-mixed concrete mixing plant was selected as the main equipment for a large industrial park project in Ho Chi Minh City, Vietnam. The project has high demands on the supply capacity and quality of the concrete.

-

Features: The ZJ-60 ready-mix plant is equipped with an advanced weighing system and a mixing mainframe, which enables it to produce high-quality concrete efficiently. The modular design of the plant makes the installation and transportation more convenient.

-

Installation and commissioning: ZOOMJO's technical team worked closely with the local partners to complete the installation and commissioning of the plant quickly. The automated control system of the plant greatly reduces the need for manual operation.

About ZOOMJO GROUP

As a professional mixing plant manufacturer, ZOOMJO provides various types of ready-mixed concrete mixing plants, including stationary and mobile ones, as well as various types of mixing mainframes, such as JS series double horizontal shaft forced mixers. With our experienced technical team, we can provide customers with all-round support from programme design, equipment selection, installation and commissioning to after-sales service.

If you are looking for high quality and high performance ready-mixed concrete mixing plant, welcome to contact ZOOMJO, we will be happy to serve you.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська