Concrete Batching Plant Process

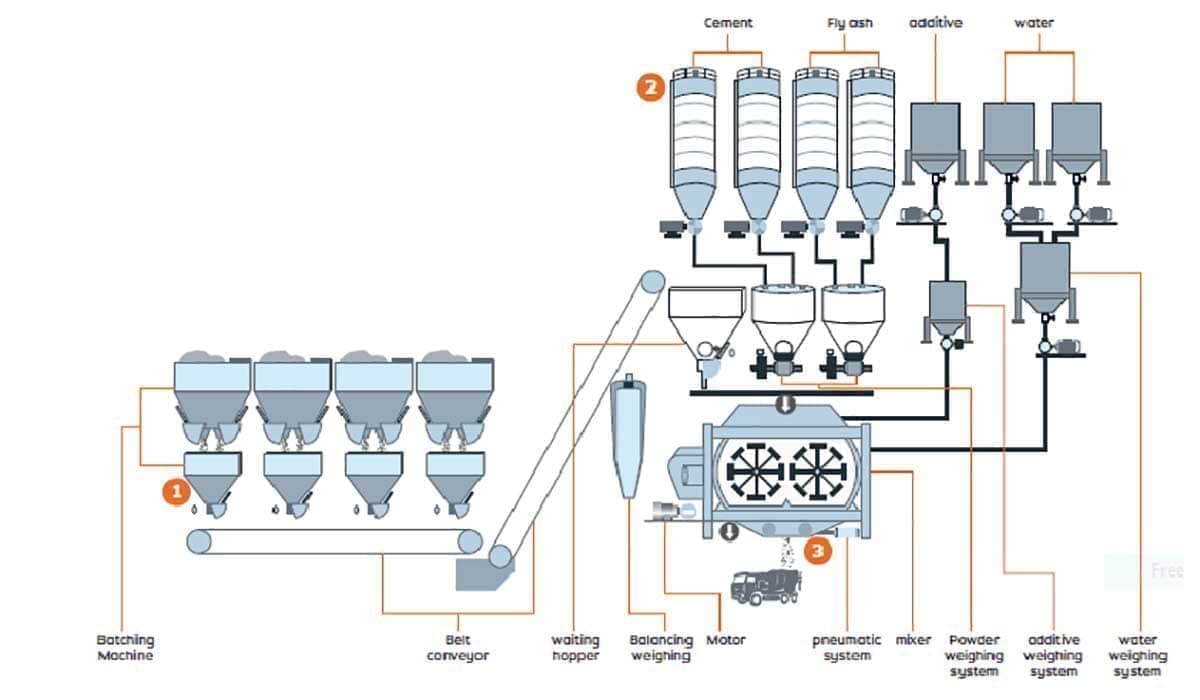

Concrete batching plant is a key facility for producing concrete, which makes concrete to meet project requirements by accurately proportioning raw materials such as cement, aggregate, water and additives. The process flow of this station covers the whole process of measuring, conveying, mixing and discharging of raw materials, which strictly guarantees the quality and homogeneity of concrete. Next, let us explore the detailed workflow of the concrete mixing plant.

Analysis of concrete mixing plant process

The process of concrete mixing plant can be divided into the following steps:

Measurement of raw materials

The main raw materials of concrete include cement, water, aggregates (such as sand and gravel) and additives. In the production process, these raw materials need to be accurately measured according to the pre-set ratio.

1. Aggregate metering: Aggregates are stored in different warehouses according to particle size, and loaded into the aggregate metering system by loader. Aggregate metering system adopts cumulative or individual metering to ensure accurate dosage of each aggregate.

2. Cement metering: Cement is transported to the metering silo through screw conveyor and weight metering is done in the silo.

3. water and additives metering: water and additives are pumped to their respective metering devices, where they are metered by weight and then injected into the mixer together.

Raw material conveying

Different raw materials are conveyed in different ways.

- Aggregate is transported to the top of the mixer by belt conveyor or bucket elevator.

- Cement is conveyed by screw conveyor

- Water and admixtures are conveyed by pumps

Mixing

Once all the raw materials are in place, the mixer starts the mixing process. The twin shaft blades in the mixer mix the raw materials well and after about 60-70 seconds, a batch of fresh concrete is prepared. Commonly used mixer types in concrete batching plants include twin shaft mixers, vertical shaft planetary mixers, single shaft mixers, forced mixers and horizontal shaft mixers.

Concrete Discharge

After mixing, the discharging door at the bottom of the mixer opens, and the concrete is transported to the construction site through the discharging hopper or pump truck.

Automated control system

Modern concrete mixing plant is equipped with intelligent control system, which can realise the whole process of automatic operation. The operator only needs to input the required concrete ratio parameters in the man-machine interface, and the control system can automatically complete the whole process from raw material measurement to mixing and discharging.

The system includes industrial computer, programmable logic controller (PLC), sensors and so on. The computer calculates the target weight of each raw material according to the preset parameters, PLC controls the start and stop of each metering system, monitors the weight data in real time and compares it with the target value, and automatically closes the metering system when it reaches the set value. At the same time, PLC also controls the operation of the mixer. Throughout the process, the real-time data of each link are monitored and recorded to ensure product quality.

Through automation control, the process of concrete mixing plant achieves high efficiency, precision and consistency of production, providing high quality concrete products for construction projects.

Advantages of Concrete Batching Plant:

Efficient production: The mixing plant is able to handle a large amount of material at one time, with high production efficiency to meet the needs of large-scale construction projects.

Precise proportioning: The precise measuring system ensures the accuracy of concrete proportioning and improves the quality of concrete.

Intelligent control: The control system can achieve automatic control of the production process, which is simple to operate and reduces labour costs.

Energy saving and environmental protection: the mixing plant adopts advanced equipment and technology, which can reduce energy consumption and pollution.

Concrete Batching Plant Manufacturer Recommendation

Since its establishment in 1995, ZOOMJO has become a professional manufacturer in the field of concrete batching plant by virtue of its profound industry experience.ZOOMJO offers a wide range of mixing plants including stationary, foundationless, mobile and portable to meet the needs of all kinds of construction projects.ZOOMJO's products are designed with high-quality materials to ensure the durability of the components and comply with the CE standard, which is known for its ZOOMJO products are designed with high quality materials to ensure component durability and comply with CE standards, and are known for their efficiency, stability and ease of maintenance.

ZOOMJO also offers a comprehensive technical support and spare parts service to ensure that customers can use the equipment without any worries. Whether you are dealing with large or small projects, ZOOMJO can provide you with customised solutions to ensure the efficient and stable operation of your plant. If you have concrete batching plant needs, please contact ZOOMJO for more information about batching plant.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська