Concrete Batching Plant Cost

Concrete batching plant is an indispensable and important equipment in construction projects, which is used for on-site concrete batching. The investment cost of the mixing plant is one of the key factors that the construction unit needs to consider when making decisions. So, how much money do you need to invest in a concrete batching plant? What are the main factors affecting the price of the mixing plant? In addition to equipment costs, the construction of a mixing plant also need to consider what other costs? This article will provide you with answers.

The price of concrete mixing plant

How much does a concrete batch plant cost?Concrete mixing plant according to the layout of the equipment can be divided into two types of fixed and mobile, the price difference is large.

- Fixed concrete mixing plants have a wide range of prices, starting from US$8,000 for the basic model HZS25 to nearly US$300,000 for the top-of-the-line HZS240. Mobile concrete mixing plants, with their compact size, can be used for a wide range of applications.

- Mobile plants, with their compact design and ease of relocation, are more affordable, starting at around US$5,000 for the entry-level YHZS25 model and going up to around US$70,000 for the high-end YHZS75 model.

In the second-hand market, the price of a mixing plant varies between US$3,000 and US$50,000, depending on the age, maintenance and overall condition of the plant.

Factors affecting the price of a mixing plant

The main reasons for the price difference are the production capacity, equipment configuration, intelligence and production process of the mixing plant.

1. Model and specification: The price of concrete mixing plant varies with different models and specifications. Generally speaking, the larger the model and the higher the specification, the higher the price of the concrete mixing plant.

2. configuration and function: the configuration and function of the concrete mixing plant will also affect the price. For example, equipped with advanced control system, high-precision metering system, high-efficiency mixing host, etc., will increase the price of concrete mixing plant.

3. Brand and quality: brand and quality are also important factors affecting the price of concrete mixing plant. The price of famous brand and high quality concrete mixing plant is relatively high, but the quality and after-sales service are also more guaranteed.

4. Market supply and demand: market supply and demand will also affect the price of concrete mixing plant. When the market demand is large, the price may rise; when the market demand is small, the price may fall.

Construction of a mixing plant need to consider other costs

Installation cost: including the cost of transport, installation and commissioning of the equipment. Usually, professional technicians are needed to guide the installation on site.

Site construction cost: a certain site is needed, including production area, storage area and office area. Site selection and construction standards directly affect the construction costs.

Personnel costs: including the wages of operators, maintenance personnel and management personnel. Through reasonable staffing and training, work efficiency can be improved and labour costs reduced.

Material cost: the main raw materials of concrete include cement, sand, stone and additives. The material cost is greatly affected by the fluctuation of market price.

Energy cost: the operation of mixing plant needs to consume a lot of electricity and water. Selecting energy-saving equipment and optimising the production process can effectively reduce the energy consumption cost.

Maintenance and repair cost: maintenance and repair of equipment are unavoidable costs. Selecting equipment with reliable quality and easy maintenance and making regular maintenance plan can reduce this part of cost.

Strategies to optimise the cost of concrete mixing plant

Accurate planning: rationally design the layout of the mixing plant to reduce the land occupation and construction costs.

Preferred equipment: Select cost-effective and energy-efficient equipment to reduce long-term operating costs.

Centralised Purchasing: Purchase raw materials in bulk and use the scale effect to reduce costs.

Energy efficiency management: Implement energy-saving measures, such as using energy-saving motors and recycling water resources.

Human Resource Management: Improve employee skills and rationalise staff allocation to reduce labour costs.

Preventive maintenance: Develop maintenance plans to reduce equipment failure and extend service life.

How to choose the right concrete mixing plant?

When choosing a suitable concrete mixing plant, the following factors should be considered comprehensively:

Project demand: Select a concrete mixing plant with suitable production capacity according to the scale of the project, concrete demand and construction progress.

Equipment Configuration: According to the specific requirements of the project, choose the appropriate equipment configuration. For example, if the project has high requirements for concrete quality, you can choose a concrete mixing plant with computer control system.

Equipment brand: choosing a famous brand of concrete mixing plant can ensure the quality of equipment and after-sales service.

Price factor: choose the most cost-effective concrete mixing plant within the budget.

The cost of concrete mixing plant is determined by many factors, including equipment configuration, technical parameters, brand effect and market demand. Choosing wisely is the key - buying the most suitable mixing plant for your needs not only reduces costs, but also improves work efficiency.

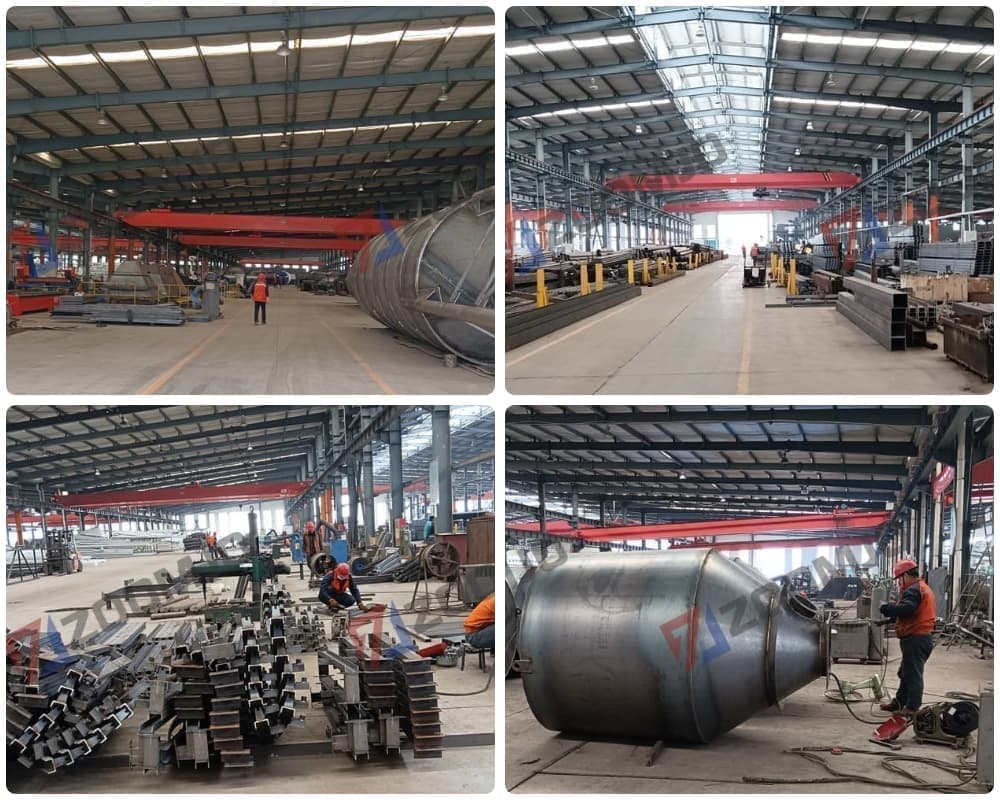

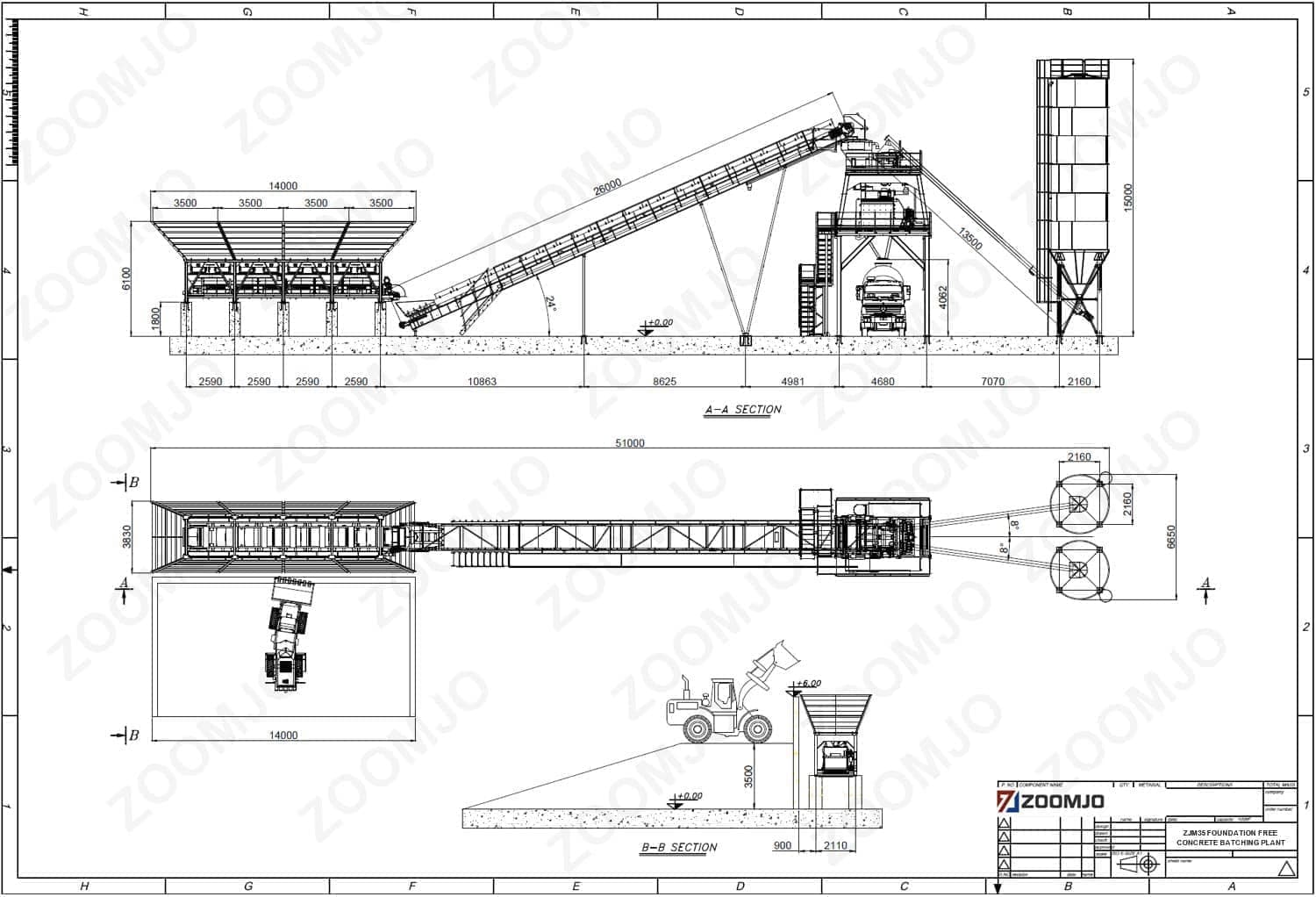

Concrete Batching Plant Manufacturer

As an industry leader, ZOOMJO is known for its high quality concrete mixing plants, offering a full range of products from stationary to mobile to portable, all at factory direct prices. zoomjo promises excellent after-sales service and has successfully exported its products to a number of countries and regions, and won the trust of customers around the world by virtue of its excellent quality and service.

Please contact ZOOMJO for detailed configurations of concrete mixing plants and to get the latest quotation, we will provide the most suitable customised solution for you.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська