Ukrainian Concrete Batching Plant for Sale

Abstract: Concrete Batching Plants Market in Ukraine is witnessing a surge in demand due to growth in the construction industry, which requires consideration of factors such as production capacity, automation, and environmental protection. The market offers mobile and stationary mixing plants and prices are influenced by various factors. Before purchasing, one should check the structure, mixing efficiency, etc. and consider suitable financing options.

Explore the Concrete Batching Plant Market in Ukraine

Exploring the Ukrainian concrete mixing plant market in depth, we found a vibrant sector full of opportunities and innovations. With the country's booming construction and infrastructure sector, the demand for concrete mixing plants has skyrocketed, providing a lucrative avenue for domestic and international suppliers. This article provides an in-depth look at the key market drivers, challenges, and diverse offerings available to ensure you make an informed decision when considering the purchase of a concrete mixing plant in Ukraine.

Understanding the market

For any potential investor or buyer, it is vital to understand the nuances of the Ukraine concrete mixing plant market. From the impact of technological advancements and government initiatives to the challenges posed by economic volatility and regulatory compliance, this article provides a comprehensive overview. With insights into market segments and top manufacturers, we guide you through the essential features to consider when purchasing a mixing plant, ensuring that your investment matches your operational needs and long-term growth goals.

Ukraine Concrete Batching Plant Market Overview

The Ukraine concrete mixing plant market has experienced significant growth in the recent past, a development that has been fuelled by the country's construction sector and infrastructural advancements. As a professional, I have observed that the demand for concrete mixing plants in Ukraine is mainly sustained by public and private construction mandates, varying from residential buildings to large commercial facilities.

Current Market Landscape

The market is characterized by a mix of local and global producers, each offering a diverse range of products to meet various job requirements. The visibility of these suppliers has actually increased competition, leading to innovations in modern technology and the types of mixing plants available for purchase.

Market Segmentation

In Ukraine, the concrete mixing plant market can be segmented on the basis of the following variables:

| Segmentation | Information |

|---|---|

| Type | Mobile, Stationary |

| Capacity | Small, Medium, Large |

| Application | Residential, Commercial, Industrial |

Key Market Drivers

There are several aspects driving the concrete batching plant market in Ukraine:

-

Infrastructure development: ongoing framework projects such as road construction and urban expansion have significantly increased the demand for concrete mixing plants.

-

Technological advancements: innovations in mixing plant technology have led to more efficient and eco-friendly options, attracting more buyers.

-

Government initiatives: supportive government programs and financial investments in the construction industry are further boosting the market.

Barriers in the market

Despite the overall positive outlook, the Ukraine concrete batching plant market faces a number of obstacles, including:

Economic volatility: economic instability may affect construction budget plans and delay projects, impacting mixing plant sales.

Regulatory compliance: adherence to stringent environmental and safety regulations can be complex and costly for both suppliers and buyers.

In conclusion, the concrete mixing plant market in Ukraine offers multiple opportunities for growth, driven by persistent demand and technological developments. However, market participants should address economic and regulatory challenges to effectively capitalize on these opportunities.

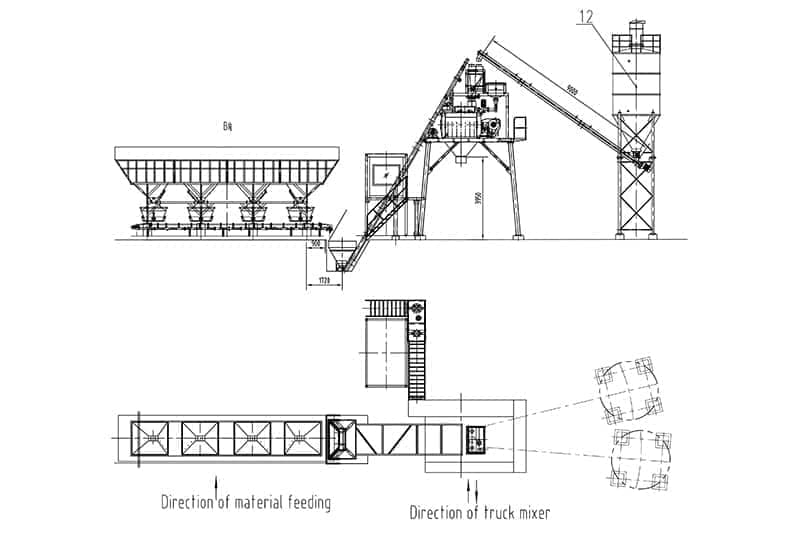

Common Configurations of Concrete Batching Plants for Sale in Ukraine

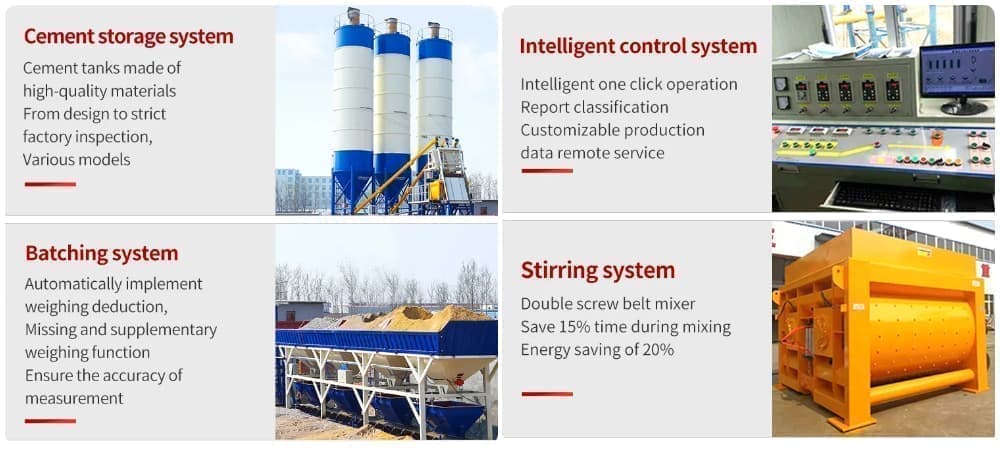

Concrete batching plants for sale in Ukraine usually have a variety of common configurations to meet the needs of different construction projects. First of all, the mixing system usually utilizes a forced concrete mixer, such as the JS500, JS750 or JS1000 models, which are capable of ensuring uniformity and high quality of the concrete. Secondly, in terms of storage systems, aggregates are usually stored in open warehouses, while cement is stored in closed silos, which usually have a storage capacity of between 20 and 200 tons and are equipped with digital displays in order to monitor residual quantities. The weighing system is a key component and covers the weighing of aggregates, powders and liquids, all of which are computerized to ensure accurate proportioning.

In addition, the batching system is capable of mixing three to six aggregates simultaneously, such as sand, rock and gravel, for efficient operation. Conveying systems include belt conveyors and screw conveyors to move materials from the storage area to the mixer. The control system usually adopts microcomputer control and supports both automatic and manual operation to provide convenience for users. Meanwhile, in order to minimize dust pollution at the construction site, the mixing plant is equipped with a dust removal system, which purifies the air through dust collectors and ducts. These configurations enable concrete mixing plants in the Ukrainian market to effectively support the development of infrastructure construction and other related projects, providing flexible, efficient and reliable concrete production solutions.

Tips to Consider When Buying Concrete Batching Plants in Ukraine

As you explore the concrete batching plant market in Ukraine, it's important to focus on a few key features to ensure you make an informed buying decision. A concrete batching plant is a significant financial investment, and understanding its important elements and features can significantly impact the success of your project.

Production capacity

The first feature to consider is the production capacity of the mixing plant. This refers to the amount of concrete the mixing plant can produce in a given period of time, usually measured in cubic meters per hour. Depending on the size of your project, you need a mixing plant that can meet your specific needs without causing delays or congestion. Evaluate your existing and future project needs to determine the perfect capacity for your process.

Types of Batching Plants

There are several types of concrete mixing plants, each suited for a different application. In Ukraine, you will find both mobile and stationary mixing plants. Mobile mixing plants offer flexibility and are perfect for projects that require frequent movement, while stationary mixing plants are suitable for long-term projects with a fixed location. Consider the nature of your tasks and logistical needs when choosing between these types.

Level of automation

The level of automation in a concrete mixing plant can significantly affect its performance and ease of operation. Modern mixing plants often include advanced control systems that allow for precise mixing and reduced manual intervention. Review the automation features offered and consider how they match your operational capabilities and labor skills.

Mixing technology

The mixing technology used in a mixing plant is another key aspect. Different mixing plants use different mixers, such as twin-shaft mixers, planetary mixers or drum mixers, each offering different advantages in terms of mixing speed, homogeneity and energy consumption. Find out which technology is best suited for the concrete mix you intend to produce.

Durability and build quality

The durability and build quality of a mixing plant are important considerations given the harsh conditions often encountered in the construction environment. Look for a mixing plant made from high-quality materials that can withstand wear and tear, ensuring a long lifespan and reduced maintenance costs. In addition, consider the manufacturer's reputation and their track record of producing reliable equipment.

Environmental Considerations

As concerns about sustainability increase, it's vital to consider the environmental impact of your concrete mixing plant. Look for features that reduce dust and noise pollution, as well as systems that effectively manage waste. Some mixing plants offer energy-efficient designs that reduce overall energy consumption, meeting environmental goals as well as saving money.

By focusing on these key features, you can ensure that the concrete mixing plant investment you purchase in Ukraine meets your operational needs and adds to the success of your construction project.

Top Manufacturers of Concrete Batching Plants in Ukraine

When you're considering purchasing a concrete mixing plant in Ukraine, it's crucial to understand the landscape of domestic manufacturers. Ukraine is home to a number of well-known manufacturers of concrete mixing plants that are known for their innovation, quality, and reliability. These suppliers offer a range of products that cater to different project needs from small-scale operations to large-scale construction projects.

Leading Manufacturers

The Ukrainian market is home to several major players in the concrete mixing plant industry. Each of these producers brings unique strengths and product offerings to the market. Below is a list of some of the top producers:

| Manufacturer | Specialty | Main Products |

|---|---|---|

| ZOOMJO | High-Capacity Mixing Plants | ZJY-120, ZJY-240 |

| BetonBud | Mobile Mixing Plants | BB-500, BB-750 |

| ConcreteTech | Eco-Friendly Options | CT-200 Eco, CT-300 Eco |

| BuildMix | Custom Mixing Plants | BM-900, BM-1200 |

ZOOMJO GROUP

ZOOMJO is a company specializing in manufacturing concrete mixing equipment, offering a wide range of concrete batching plants to meet the needs of different customers. ZOOMJO's concrete batching plants are becoming more and more popular in the market with the increasing number of infrastructures being built.

-

Stationary batching plant: suitable for large-scale construction projects, designed for high-volume production.

-

Mobile batching plants: facilitate rapid deployment on different construction sites and are suitable for projects requiring flexibility.

Capacity ranges from 25 m³/h to 240 m³/h with specific models 25, 35, 50, 60, 75, 90 and up to 120 m³/h.

BetonBud

BetonBud specializes in mobile concrete mixing plants for projects that require flexibility and wheelchair access. Their BB-500 and BB-750 models are particularly popular because of their ease of transportation and quick setup times, allowing for reliable operation on site.

ConcreteTech

ConcreteTech specializes in providing eco-friendly options for the concrete mixing plant market. Their CT-200 Eco and CT-300 Eco designs incorporate sustainable innovations that reduce environmental impact, which is critical for environmentally conscious projects.

BuildMix

BuildMix offers very customizable concrete mixing plants, allowing customers to tailor their equipment to their specific project needs. Their BM-900 and BM-1200 models are known for their flexibility and advanced features, making them a flexible choice for a wide range of construction needs.

Comparing Mobile vs Stationary Concrete Batching Plants

One of the main choices you will face when considering purchasing a Ukrainian concrete batching plant is whether to choose a mobile or stationary model. Each type has its own unique advantages, and the choice will largely depend on your specific project needs and operational requirements.

Mobility and Flexibility

Mobile concrete mixing plants offer the unique advantage of wheelchairs. These mixing plants are designed to be easily transferred and set up in multiple locations, making them ideal for projects that require frequent relocation. The flexibility they offer is especially useful for construction tasks that are spread across multiple locations or in remote areas where setting up a permanent mixing plant is not feasible.

On the other hand, stationary concrete mixing plants are fixed installations. They are usually suitable for long-term projects where the mixing plant stays in one area for a long time. The security and capacity of a stationary mixing plant usually results in higher production costs, which can be advantageous for meeting the demands of large construction projects.

Installation and Setup

The installation process is also very different between the two types. Mobile mixing plants are designed to be set up and dismantled quickly. They usually have a compact design and require minimal groundwork, which reduces the time and costs associated with installation. This makes them an economical choice for time-critical tasks.

On the other hand, fixed mixing plants require a more robust structure and installation process. While this may involve a larger initial investment and longer installation time, the investment pays off in terms of durability and performance in the long-term program.

Production capacity and efficiency

When it comes to production capacity, stationary mixing plants typically offer higher levels of output than mobile mixing plants. This stems from their larger size and sturdier build, allowing them to handle more material and produce concrete at a faster rate. For projects with high volume requirements, a stationary mixing plant may be the more appropriate choice.

While mobile mixing plants typically offer lower capacity, they are able to adapt to different project sizes and issues. They are particularly well suited for small to medium-sized projects, where the capacity of a mobile mixing plant is a significant advantage.

Price Considerations

Cost is another important factor to consider. Mobile concrete batching plants typically have a low initial cost due to their smaller size and simple installation requirements. However, the total cost of ownership may vary depending on the frequency of relocation and the logistics costs involved.

Fixed mixing plants, while typically more costly upfront, can provide better long-term value for projects with ongoing, high-capacity needs. The efficiency and durability of these mixing plants can reduce operating costs over time, making them a beneficial investment for large, permanent programs.

Factors Affecting the Price of Concrete Batching Plants in Ukraine

When you are considering purchasing a concrete batching plant in Ukraine, it is crucial to understand the factors that influence the price. Multiple factors may affect the cost, from production capacity to technical features. These factors are explored below to provide a detailed overview for potential buyers.

1. Production capacity

The production capacity of a concrete batching plant is one of the main determinants of its price. Batching plants with higher capacities are usually more expensive because they can produce more concrete per hour. Purchasers should evaluate their job requirements to determine the appropriate capacity, balancing cost with operational needs.

2. Technology and automation

Advanced technology and automation features can significantly impact price. Modern mixing plants equipped with electronic controls and automation systems offer enhanced efficiency and accuracy and typically justify a higher price point. However, for projects with limited budgets, it may be more cost-effective to choose a mixing plant with standard features.

3. Type of mixing plant: mobile vs. stationary

The difference between choosing a mobile versus a stationary mixing plant can also affect price. Mobile mixing plants are popular for their flexibility and ease of installation, and usually carry a premium for these advantages. In contrast, fixed mixing plants are usually more durable and suitable for larger projects, and may offer more cost-effective advantages in terms of durability and output.

4. Brands and manufacturers

The reputation and quality associated with different manufacturers can lead to price differences. Established brands with a history of reliability and performance may charge more for their products. Buyers must consider the trade-off between cost and quality assurance when choosing a manufacturer.

5. Customization and extra features

Customization options and additional features, such as enhanced mixing capabilities or environmental controls, can add to the overall cost. While these features can improve the efficiency of the mixing plant and compliance with local regulations, they should be evaluated based on project-specific needs.

6. Market conditions and supply chain factors

Fluctuating market demand and supply chain factors, such as economic issues, import and export tariffs, and availability of raw materials, can affect the price of a concrete mixing plant. Staying on top of market trends can help clients make strategic investment choices.

| Variable | Impact on Price |

|---|---|

| Production Capacity | Higher capacity increases price |

| Technology and Automation | Advanced features increase price |

| Type of Mixing Plant | Mobile mixing plants are usually more expensive |

| Brand and Manufacturer | Well-reputed brands may charge higher fees |

| Customization | Additional features increase price |

| Market Conditions | Variations can affect pricing |

How to Choose the Right Concrete Batching Plant for Your Project

When you're considering purchasing a concrete batching plant in Ukraine, it's crucial to choose the right type that matches the specific needs of your project. The choice between different models and configurations can significantly impact the efficiency and cost-effectiveness of your operation. Here are some important considerations to guide your decision-making process:

Understanding your project needs

Begin by assessing the size and nature of your project. Determine the volume of concrete you will need to produce per day and the duration of your project. Projects with high demand and long timelines may benefit from a larger stationary mixing plant, while smaller, short-term projects may be better suited for a mobile mixing plant.

Assessing production capacity

The production capacity of a concrete mixing plant is an important factor. Evaluate the capacity of the mixing plant to ensure it meets the needs of your project. Considerations include set size, mixing time and cycle time. A mixing plant with insufficient capacity can lead to delays and increased costs, while an over-capacity mixing plant may not be cost-effective.

Consider mobility and flexibility

If your project involves multiple locations or requires frequent movement, a mobile concrete mixing plant may be helpful. These mixing plants offer flexibility and easy transportation, allowing you to quickly set up and tear down the operation. However, if your project is stationary and requires large quantities of concrete, a stationary mixing plant may be more appropriate.

Evaluate technical features

Modern concrete mixing plants include advanced technological features that improve performance and accuracy. Look for mixing plants equipped with automated controls, real-time tracking systems, and high-quality mixing technology. These features can maximize the production process, reduce waste, and improve the quality of the concrete produced.

Analyzing the Cost Impact

While it may be tempting to choose the cheapest option, it's important to consider the long-term cost impact. Review the initial purchase price, operating costs, maintenance costs and potential downtime. A mixing plant that offers a balance between cost and quality can provide better value throughout its lifecycle.

Evaluate the manufacturer's reputation

When purchasing a concrete mixing plant, it is crucial to choose a trustworthy supplier. Research the reputation of Ukrainian manufacturers, focusing on their experience, customer reviews and after-sales service. A reputable manufacturer will provide high-quality products and reliable support, ensuring smooth operations throughout your project.

By carefully considering these factors, you can choose the most suitable Ukraine concrete batching plant that will meet the needs of your project and contribute to its overall success.

Tips for checking before buying a concrete batching plant

When you're considering purchasing a Ukraine concrete batching plant, it's vital to conduct a thorough inspection to ensure you get a reliable and efficient unit. Below are important tips to guide you through this process.

Check the structural integrity

The first step is to assess the structural integrity of the mixing plant. Make sure the structure is sturdy and shows no signs of corrosion or damage. Pay special attention to the load-bearing elements to confirm that they are in good condition.

Check Mixer Efficiency

The mixer is an important part of any concrete mixing plant. Evaluate the mixer for damage and confirm that it is running smoothly and without unusual noise. Make sure the mixer blades are sharp and effective in producing a uniform mix.

Check the control system

Control systems should be easy to use and practical. Check for outdated software and make sure the system can batch accurately. Verify that all sensors and indicator lights are working properly.

Checking the weighing mechanism

The accuracy of the weighing is critical to maintaining the quality of the concrete. Check the weighing system to ensure it provides accurate measurements. Calibration records should be available for review.

Review the capacity and output of the mixing plant

Understanding the capacity and output of the mixing plant is critical. Verify that the mixing plant can meet the needs of your project. Consider the cycle time of the mixing plant and its ability to efficiently produce the required amount of concrete.

Check conveyor belts and hoppers

Conveyor belts and hoppers should be free of clogging and damage. Check for signs of wear and make sure they are running smoothly. Proper alignment and tension of the conveyor belts is essential for reliable operation.

Check maintenance records

Evaluate the maintenance history of your mixing plant to see how well it has been maintained. Regular maintenance is a good indicator of a well-maintained mixing plant. Look for any ongoing issues that may indicate potential problems.

| Assessment Area | Key Points |

|---|---|

| Structural Integrity | Check for corrosion, damage, and efficiency |

| Mixer Efficiency | Assess wear, smooth operation, and sharp blades |

| Control System | Ensure functionality, check software, and sensor operation |

| Weighing Mechanism | Test accuracy and review calibration records |

| Capacity and Output | Confirm the mixing plant meets project requirements |

| Conveyor Belts and Hoppers | Check for blockages, damage, and proper placement |

| Maintenance Records | Review history of regular maintenance and issues |

Financing Options for Buying a Concrete Batching Plant in Ukraine

When you are considering purchasing a concrete batching plant in Ukraine, it is critical to understand the financing options available. This section will provide insight into the many financing methods that can help facilitate your investment in this critical piece of construction equipment.

Bank Loans

One of the most common financing options is a small business loan. Ukrainian banks offer a range of loan products geared toward business investments, including the purchase of industrial equipment, such as concrete mixing plants. When choosing a small business loan, make sure you have a strong business plan and financial statements to support your application. Interest rates and financing terms may vary, so it is advisable to compare quotes from multiple banks.

Leasing

Leasing is another viable option that allows you to use a concrete batching plant without having to purchase it outright. This is especially beneficial for businesses that need to manage their cash flow efficiently. Lease agreements usually involve monthly payments over a specific period of time, at the end of which you may have the right to purchase the equipment.

Equipment Financing Companies

Specialized equipment financing companies can provide customized financing solutions for the purchase of a concrete mixing plant. These companies typically offer more flexible terms than traditional banks, and they understand the specific needs of the construction industry.

Government grants and subsidies

At times, the Ukrainian government may offer grants or subsidies to support industrial development and growth. Investigating whether your purchase qualifies for such financial assistance can significantly reduce the total cost of investment.

Supplier Financing

Some manufacturers or suppliers of concrete mixing plants may offer vendor financing. This option allows you to finance your purchase directly with the seller, often with reasonable interest rates and flexible payment plans customized to your business needs.

| Financing Option | Advantages | Considerations |

|---|---|---|

| Bank Loans | Access to large funds, structured payment plans | Requires strong financial documentation, possibly higher interest rates |

| Leasing | Lower initial cost, flexibility | Ownership at the end of the term may incur additional costs |

| Equipment Financing Companies | Industry-specific terms, flexible plans | Interest rates may vary, requires comprehensive comparison |

| Government Grants/Subsidies | May reduce overall costs | Eligibility criteria, limited availability |

| Vendor Financing | Practical, often competitive pricing | Limited to specific vendors, may have shorter terms |

In conclusion, choosing the right financing option for purchasing a concrete mixing plant in Ukraine requires careful consideration of your business's financial situation and long-term goals. By reviewing each option and consulting with a financial expert, you can make informed decisions that support your operational needs and growth goals.

Frequently Asked Questions about Concrete Batching Plants for Sale in Ukraine

What is driving the demand for concrete batching plants in Ukraine?

Demand is primarily driven by the expanding construction industry and infrastructure development in Ukraine, including public and private projects ranging from residential buildings to industrial complexes.

What types of concrete batching plants are available in Ukraine?

In Ukraine, you can find both mobile and stationary concrete batching plants. Mobile batching plants offer flexibility for projects that require frequent relocation, while stationary batching plants are suitable for long-term, fixed-location projects.

What factors should I consider when buying a concrete batching plant?

Key factors include production capacity, type of mixing plant (mobile or stationary), level of automation, mixing technology, durability and environmental considerations. These factors will affect the efficiency and cost-effectiveness of your operation.

Who are the leading manufacturers of concrete mixing plants in Ukraine?

Leading manufacturers include ZOOMJO Group, BetonBud, ConcreteTech, and BuildMix.Each manufacturer offers unique benefits such as high capacity mixing plants, mobile solutions, environmentally friendly designs, and customization options.

What's the difference between mobile and stationary concrete mixing plants?

Designed for easy transportation and quick setup, mobile batching plants are ideal for projects with multiple locations. Stationary batching plants offer higher capacity and are suitable for large, permanent projects.

What factors affect the price of a concrete batching plant in Ukraine?

Price factors include production capacity, technology and automation, type of mixing plant, brand reputation, customization options and market conditions. Understanding these can help you make an informed buying decision.

What financing options are available for purchasing a concrete batching plant?

Options include bank loans, leasing, equipment finance companies, government grants/subsidies and vendor financing. Each option offers different advantages and considerations based on your financial situation and business needs.

How can I ensure the quality of my concrete batching plant before I buy it?

Check key areas such as structural integrity, mixer efficiency, control systems, weighing mechanisms and maintenance records. A thorough inspection ensures you get a reliable and efficient unit.

Why is it important to choose the right concrete batching plant for my project?

Choosing the right mixing plant ensures that it meets the specific needs of your project, impacting the efficiency and cost-effectiveness of your operation. Consider factors such as project size, production requirements, mobility and technical features.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська