Concrete Batching Plant Bunkers

Concrete batching plant bunker is an important part of the concrete batching plant, which is responsible for processing and categorizing aggregates to produce ready-mixed concrete with different structures. Aggregate is one of the main materials of concrete, and its size and quality directly affect the performance and use of concrete. Therefore, the role of bunker in concrete mixing plant is to ensure the reasonable proportion and accurate measurement of aggregates to meet different project requirements.

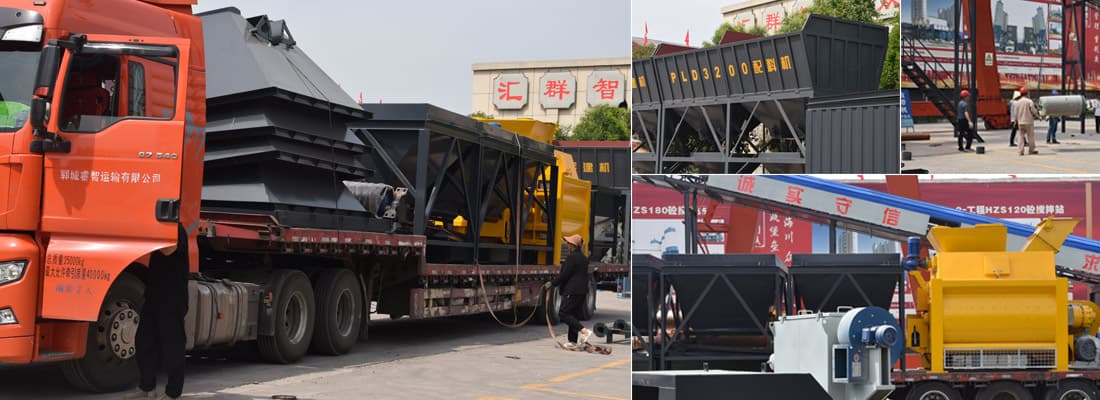

Bunkers usually consist of several independent chambers, each of which can store different sizes of aggregates. During the production process, the aggregate enters the bunker through the inlet and is then transported to the mixer via chute or conveyor belt. The design and structure of the bunker has a significant impact on the efficiency and production capacity of the concrete batching plant. When designing and building a concrete batching plant, you need to consider the structure, size, material and other factors of the bunker.

The classification of concrete batching plant bunkers is mainly based on the type of concrete batching plant. Stationary concrete batching plant bunkers generally have a capacity of between 50 cubic meters and 200 cubic meters, which can store a large amount of aggregates to meet the needs of large-scale concrete production.

Mobile concrete batching plant bunkers generally have a capacity of 10 cubic meters to 50 cubic meters, which can store a moderate amount of aggregates to meet the needs of small and medium-sized concrete production. Mobile concrete batching plant bunkers typically have between 2 and 4 bins, allowing for the sorting of commonly used sizes of aggregates to suit common concrete types and strength levels.

Concrete batching plant bunkers also require regular maintenance and servicing to ensure proper operation and long service life. For example, the bunkers need to be regularly cleaned of debris and buildup, the sealing and integrity of the bunkers need to be checked, as well as worn parts need to be replaced on a regular basis.

The following factors should be considered when selecting a bunker for a concrete mixing plant:

✔️ The different fields of use of ready-mixed concrete require different sizes of aggregates, and the appropriate type of bunker should be selected according to the field of use of ready-mixed concrete.

✔️ The production volume of ready-mixed concrete is different, and the production capacity requirements of bunkers are also different, and the suitable bunker type should be selected according to the production volume of ready-mixed concrete.

✔️ Different types and models of bunkers have different costs, and the right bunker should be selected according to the budget.

ZOOMJO is a 28 year old concrete equipment manufacturer of concrete batching plants and a wide range of concrete mixing equipment. Our products cover three types: stationary, mobile and foundationless, with concrete output ranging from 25 cubic meters to 240 cubic meters per hour. We also provide related concrete plant accessories. If you are interested in our products or would like more information, please feel free to contact us.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська