Concrete Batching Plants for Sale in Australia

Concrete Batching Plants in Australia

In the bustling landscape of Australia's construction industry, concrete batching plants are pivotal to ensuring a steady supply of high-quality concrete. As an expert in the field, I delve into the various types of concrete batching plants for sale in Australia, highlighting their unique features and benefits, from mobile to stationary, catering to diverse project needs.

Exploring the market dynamics, I uncover the top suppliers and provide insights into cost considerations, maintenance tips, and future trends shaping the industry. Whether you're seeking flexibility or high-capacity production, understanding these elements is crucial for making informed decisions about concrete batching plants in Australia.

Review of Concrete Batching Plants in Australia

As a professional in the field of building and concrete manufacturing, I have observed the substantial role that concrete batching plants play in the Australian building market. These plants are crucial in making certain the constant production of high-grade concrete, which is crucial for different construction tasks ranging from residential structures to large-scale framework advancements.

The Importance of Concrete Batching Plants

Concrete batching plants are centers where the active ingredients of concrete are mixed to produce concrete. These plants are developed to attain the best mix of concrete, water, sand, and aggregates, making sure that the resulting concrete satisfies certain job requirements. In Australia, the demand for concrete batching plants has actually been steadily increasing due to the country's durable building and construction sector and the requirement for reliable, trustworthy, and top notch concrete production.

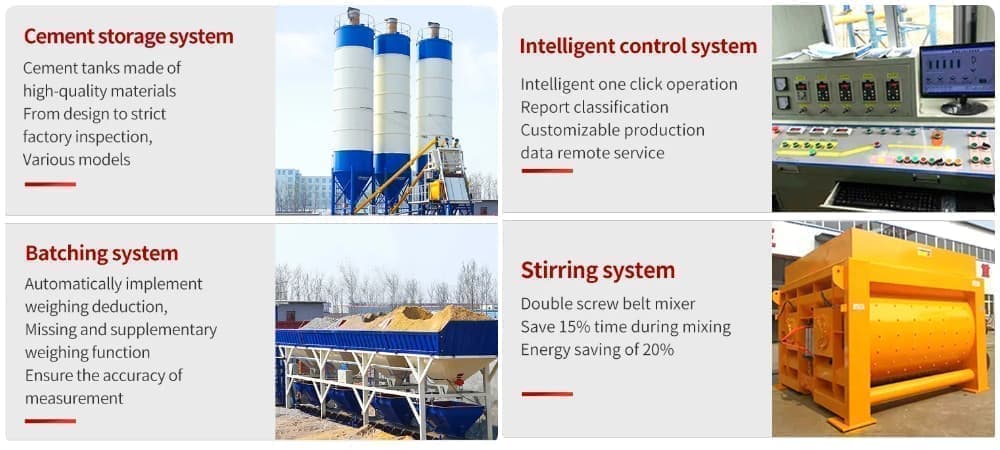

Secret Components of Concrete Batching Plants

A common concrete batching plant in Australia contains a number of essential elements, each playing an important duty in the manufacturing process:

| Component | Function |

|---|---|

| Combining System | Combines all ingredients to generate concrete |

| Accumulated Batching System | Stores and actions aggregates such as sand and crushed rock |

| Cement Silo | Stores and dispenses concrete |

| Control System | Automates and keeps an eye on the manufacturing process |

| Conveyor System | Transportations materials within the plant |

Market Dynamics in Australia

The Australian market for concrete batching plants is identified by a varied array of alternatives accommodating various project needs. The marketplace is supported by a mix of regional and worldwide providers that provide both fixed and mobile batching plant services. The option in between these choices relies on elements such as project dimension, location, and details requirements.

With the building industry in Australia continually advancing, there is an expanding emphasis on sustainability and performance. This has resulted in advancements in batching plant technology, including the growth of eco pleasant systems that minimize waste and energy consumption.

Overall, concrete batching plants are an indispensable component of the building landscape in Australia, giving the backbone for the production of high-quality concrete that fulfills the needs of modern-day construction projects.

Kinds Of Concrete Batching Plants Available to buy

Mobile Concrete Batching Plants

Mobile concrete batching plants are designed for versatility and ease of movement. These plants are excellent for jobs where the construction website is not dealt with, permitting quick setup and dismantling. They are specifically useful in remote locations where framework is restricted. Mobile batching plants often come furnished with wheels for very easy transportation and are generally portable, making them suitable for tasks with area restraints.

Stationary Concrete Batching Plants

Fixed concrete batching plants are designed for long-term use at a dealt with location. These plants are typically larger in dimension and deal greater production capacities compared to their mobile equivalents. They are ideal for tasks that require a regular supply of concrete over an extended period. Stationary plants are usually furnished with sophisticated functions such as automated controls and high-capacity mixers, guaranteeing high-quality concrete manufacturing.

Compact Concrete Batching Plants

Compact concrete batching plants are a best option for tiny to medium-scale tasks. They provide a balance in between flexibility and manufacturing capability, making them versatile for different construction requirements. These plants are made to be quickly transported and put together, which is useful for projects with restricted space or spending plan restraints. In spite of their smaller dimension, small plants maintain high efficiency and dependability.

Horizontal Concrete Batching Plants

Horizontal concrete batching plants are understood for their efficiency and ease of operation. They are defined by their horizontal design, which allows for a structured production process. These plants are ideal for high-volume concrete production and are frequently used in massive framework projects. The horizontal style assists in easy upkeep and cleaning, adding to the longevity of the devices.

Vertical Concrete Batching Plants

Vertical concrete batching plants are made to maximize room usage and production efficiency. These plants have a vertical layout, which permits for gravity-assisted material flow, decreasing energy intake and raising manufacturing speed. Upright plants are ideal for city locations where space is restricted, and they use high precision in concrete blending, making them suitable for tasks requiring certain concrete formulas.

Secret Features to Consider When Buying a Concrete Batching Plant

When buying a concrete batching plant offer for sale in Australia, it is vital to assess numerous crucial attributes that can dramatically impact operational efficiency and cost-effectiveness. Understanding these features will certainly help ensure that the investment fulfills your specific requirements and sector requirements.

Production Capacity

The manufacturing capability of a concrete batching plant is just one of the most essential variables to think about. This describes the volume of concrete that can be generated within a given period, generally gauged in cubic meters per hour. Picking a plant with the proper capacity is important to meet project needs without exhausting resources.

| Plant Type | Production Capacity (m ³/ h) |

|---|---|

| Small-Scale | 15-30 |

| Medium-Scale | 30-60 |

| Massive | 60-120 |

Automation Level

The degree of automation in a concrete batching plant can greatly influence functional effectiveness. Automated systems can manage the whole batching procedure with minimal human treatment, lowering labor prices and reducing mistakes. Consider whether a completely automated, semi-automated, or hand-operated system best suits your needs.

Combining Technology

The kind of mixing technology used in the plant is an additional essential attribute. Twin-shaft mixers, planetary mixers, and drum mixers prevail types, each using various advantages in terms of blending rate, consistency, and energy consumption. It's vital to select the modern technology that straightens with the particular requirements of your tasks.

Wheelchair

Think about whether a mobile or fixed batching plant is better for your operations. Mobile plants provide versatility and can be conveniently transferred to different sites, making them suitable for temporary projects. On the other hand, stationary plants are extra ideal for lasting tasks where high quantity production is necessary.

Ecological Considerations

With increasing focus on sustainability, it is crucial to examine the ecological influence of the batching plant. Seek features that decrease dirt discharges, lessen environmental pollution, and advertise efficient power use. Some plants are geared up with advanced dirt collection systems and noise decrease innovations to meet environmental criteria.

Cost and Budget

The price of a concrete batching plant is a considerable consideration. It is vital to stabilize budget plan constraints with the demand for top quality and efficiency. Review the complete price of possession, including preliminary acquisition price, functional costs, maintenance, and prospective downtime.

| Attribute | Significance |

|---|---|

| Manufacturing Capacity | High |

| Automation Level | Medium |

| Combining Technology | High |

| Mobility | Variable |

| Environmental Considerations | Increasing |

| Expense and Budget | Critical |

Top Suppliers of Concrete Batching Plants in Australia

When considering the acquisition of concrete batching plants for sale in Australia, it is essential to identify the leading vendors that can supply reputable and top notch tools. The adhering to areas highlight some of the leading providers in the Australian market, recognized for their commitment to quality and customer complete satisfaction.

ZOOMJO GROUP

ZOOMJO GROUP is a famous distributor in the building industry, offering a vast array of concrete batching plants. Understood for their robust and effective layouts, ZOOMJO supplies both fixed and mobile batching plants that cater to different job dimensions and demands. Their plants are equipped with the most recent modern technology to ensure precision and performance in concrete manufacturing.

Boral Australia

Boral Australia is one more principal out there, identified for its cutting-edge solutions and lasting techniques. Boral offers a detailed array of concrete batching plants that are made to meet the varied needs of the building industry. Their plants are understood for their toughness, convenience of operation, and capability to generate high-quality concrete constantly.

Holcim Australia

Holcim Australia stands apart as a supplier dedicated to providing high-performance concrete batching plants. Their offerings consist of both common and customized options, making certain that clients receive equipment that lines up with their specific task goals. Holcim's plants are designed to maximize productivity while reducing ecological effect, making them a favored option for eco mindful projects.

Batchcrete International

Batchcrete International is an expert vendor of concrete batching plants, supplying a selection of models to fit various applications. They concentrate on delivering versatile and cost-effective remedies, with an emphasis on ingenious style and user-friendly procedure. Batchcrete's commitment to customer support and technical assistance makes them a dependable partner for building tasks throughout Australia.

Concrete Equipment Suppliers Australia

Concrete Equipment Suppliers Australia is recognized for its comprehensive range of concrete batching plants, providing to both small and massive construction projects. They offer top notch equipment that is both resilient and reliable, making sure optimum performance in different operating conditions. Their group of professionals supplies thorough support, from equipment option to installation and upkeep.

Comparing Mobile vs. Stationary Concrete Batching Plants

When checking out concrete batching plants for sale in Australia, it's crucial to recognize the distinctions in between mobile and stationary batching plants. Each type supplies distinct benefits that accommodate different functional demands and project needs.

Movement and Flexibility

Mobile concrete batching plants are made for flexibility and simplicity of transportation. These plants are excellent for jobs that require regular relocation, such as roadway building and construction or remote website operations. The vital benefit of mobile plants is their capacity to be rapidly constructed and taken apart, permitting fast arrangement and marginal downtime.

Manufacturing Capacity

Fixed concrete batching plants, on the other hand, are constructed for high-volume production. They are generally made use of for large jobs where the demand for concrete corresponds and considerable. These plants are geared up with bigger mixers and storage capacities, guaranteeing a consistent supply of concrete.

| Feature | Mobile Batching Plants | Stationary Batching Plants |

|---|---|---|

| Mobility | Highly mobile, easy to transfer | Repaired location, less wheelchair |

| Configuration Time | Quick setup and teardown | Longer arrangement time |

| Production Capacity | Reduced capability, appropriate for smaller sized tasks | Higher capability, ideal for huge projects |

| Cost | Generally reduced initial cost | Higher preliminary investment |

Price Considerations

The price of a batching plant can substantially affect the decision to choose between mobile and fixed choices. Mobile plants usually have a reduced preliminary price due to their smaller size and capacity. Nevertheless, they could sustain greater functional prices if frequent movings are called for. Alternatively, fixed plants demand a greater initial investment yet can be much more cost-effective in the future for jobs calling for high manufacturing quantities.

Operational Efficiency

Functional performance is another crucial element. Fixed plants usually supply better performance due to their durable style and bigger equipment, which can handle extra substantial lots and constant operation. Mobile plants, while effective in their own right, might not match the output levels of their stationary counterparts.

Environmental Impact

Ecological considerations likewise contribute in the decision-making procedure. Mobile plants have a tendency to have a smaller ecological footprint due to their compact design and minimized site impact. Stationary plants, nonetheless, can be optimized for environmental efficiency through sophisticated modern technologies and lasting practices.

Price Analysis of Concrete Batching Plants in the Australian Market

Comprehending the Price Range

When exploring concrete batching plants available for sale in Australia, it's critical to understand the varied price range that these plants can drop right into. The price of a concrete batching plant can differ substantially based upon factors such as the kind of plant, its capacity, and the innovation it integrates. Generally, costs can range from AUD 30,000 for a tiny, fundamental plant to over AUD 500,000 for a high-capacity, totally automated plant.

Elements Influencing Cost

Numerous factors affect the cost of concrete batching plants. Ability is a main component; bigger plants efficient in generating much more concrete per hour will naturally be much more pricey. Innovation is another variable, with modern plants including advanced automation and control systems commanding greater prices. Additionally, the brand and beginning of the equipment can influence rates, as imported plants might sustain extra delivery and import responsibilities.

First Investment vs. Long-term Savings

While the preliminary financial investment in a concrete batching plant can be significant, it's vital to take into consideration the long-term cost savings and efficiencies that a high-grade plant can provide. Advanced plants frequently consist of attributes that decrease waste, boost accuracy, and boost performance, which can result in substantial expense savings in time. Moreover, energy-efficient versions can assist in lowering functional costs, adding to a more lasting organization design.

Contrasting New vs. Used Equipment

One more element to consider in the price evaluation is whether to acquire new or secondhand tools. While new plants come with the current innovation and service warranties, utilized plants can supply significant savings. It is crucial to weigh the benefits of the newest functions against the possible expense savings of previously owned equipment, making certain that any kind of utilized plant is completely evaluated for wear and possible repair work prices.

Financing Options

Lots of suppliers offer funding choices to aid organizations in getting concrete batching plants. Adaptable layaway plan, renting options, and also federal government incentives for building and construction and infrastructure advancement can play a duty in making the purchase a lot more economical. It's a good idea to check out these alternatives to locate a service that best fits the monetary method of your organization.

Maintenance Tips for Prolonging the Lifespan of Concrete Batching Plants

Ensuring the durability of concrete batching plants is essential for optimizing their performance and roi. Normal upkeep not only enhances efficiency however likewise minimizes unexpected downtime. Here are crucial tips to aid keep your concrete batching plants properly.

Routine Inspection and Cleaning

Regular evaluations are important to determine deterioration early. Inspect components like mixers, belts, and silos for indicators of damages. Cleansing the plant on a regular basis stops the buildup of concrete residue, which can trigger blockages and impact efficiency.

Lubrication of Moving Parts

Appropriate lubrication of moving parts is necessary to minimize friction and stop wear. Make certain that all bearings, chains, and equipments are adequately lubricated according to the producer's requirements. This technique not just prolongs the life expectancy of the devices but also makes certain smooth operation.

Calibration of Weighing Systems

Exact evaluating is critical for the top quality of concrete production. Normal calibration of the considering systems ensures precision in blending ratios. This can be done monthly or as recommended by the devices manufacturer.

Electric System Checks

The electric elements of a concrete batching plant must be evaluated on a regular basis to stop malfunctions. Look for loose links, damaged wires, and ensure that all sensing units are functioning correctly. Timely repair work can avoid significant electrical failures.

Upkeep Schedule

Embracing a structured maintenance routine is vital. Right here's a standard guideline:

| Maintenance Task | Regularity |

|---|---|

| Assessment of mechanical elements | Weekly |

| Lubrication of moving components | Bi-weekly |

| Calibration of evaluating systems | Month-to-month |

| Electric system assessment | Quarterly |

| Comprehensive cleaning | Regular monthly |

Training and Documentation

Guarantee that all operators and upkeep employees are properly learnt operating and preserving the concrete batching plant. Maintaining detailed maintenance records can aid track the background of repair services and replacements, assisting in future diagnostics.

Use Quality Spare Parts

When replacements are necessary, always use high-quality spare parts from credible providers. This makes sure compatibility and durability, decreasing the threat of regular break downs.

By sticking to these upkeep suggestions, you can significantly prolong the life expectancy of your concrete batching plants, ensuring they stay a trusted asset in your operations.

Future Trends in the Australian Concrete Batching Plant Industry

The concrete batching plant sector in Australia is advancing swiftly, driven by technological advancements, environmental considerations, and changing market needs. As we look to the future, a number of essential trends are anticipated to form the landscape of concrete batching plants in the country.

Technological Advancements

One of the most substantial trends is the combination of advanced technologies in concrete batching plants. Automation and digitalization are coming to be increasingly widespread, permitting extra accurate control over the mixing procedure. This not only improves the high quality of the concrete generated yet additionally boosts operational performance. For example, using IoT (Internet of Things) and AI (Artificial Intelligence) systems enables real-time surveillance and anticipating maintenance, decreasing downtime and optimizing production schedules.

Ecological Sustainability

As environmental concerns remain to grow, the sector is observing a change towards more sustainable techniques. There is a rising demand for environmentally friendly concrete batching plants that reduce waste and lower carbon discharges. Innovations such as using recycled materials in concrete manufacturing and the advancement of energy-efficient machinery are obtaining grip. Furthermore, governing stress are pushing manufacturers to take on greener innovations, which is expected to drive further improvements in this location.

Personalization and Flexibility

The demand for tailored remedies is becoming more obvious as construction tasks come to be more complex and varied. Concrete batching plants are being created with higher versatility to satisfy certain project demands. This consists of the capability to produce various kinds of concrete mixes and the option to switch between stationary and mobile arrangements easily. Such adaptability is critical for meeting the differing demands of the Australian building and construction market.

Market Growth and Opportunities

The Australian concrete batching plant market is positioned for growth, sustained by continuous framework growth and urbanization. The need for domestic, business, and commercial construction tasks is driving the requirement for reliable and dependable concrete manufacturing remedies. Therefore, there are many opportunities for suppliers and suppliers to broaden their offerings and capture a larger market share.

Market Challenges and Solutions

Regardless of the positive overview, the market faces several challenges, consisting of labor lacks and supply chain disturbances. To resolve these concerns, business are buying workforce training and discovering alternative supply chain methods. In addition, partnerships and cooperations with modern technology carriers are aiding to get rid of these difficulties and make sure a consistent supply of premium concrete batching plants.

| Fad | Influence |

|---|---|

| Technological Advancements | Boosted performance and top quality |

| Environmental Sustainability | Lowered carbon impact and waste |

| Personalization and Flexibility | Versatility to project needs |

| Market Growth | Raised demand for building jobs |

| Market Challenges | Required for cutting-edge remedies |

To conclude, the future of the concrete batching plant market in Australia is brilliant, with numerous possibilities for growth and innovation. By remaining in harmony with arising patterns and embracing new modern technologies, sector gamers can place themselves for success in this vibrant market.

FAQs on Concrete Batching Plants for Sale in Australia

What are the key types of concrete batching plants available in Australia?

In Australia, you can find several types of concrete batching plants, including mobile, stationary, compact, horizontal, and vertical batching plants. Each type caters to different project requirements and operational needs.

Why is the production capacity of a concrete batching plant important?

The production capacity determines how much concrete a plant can produce in a given time frame, usually measured in cubic meters per hour. It is crucial to select a plant with the appropriate capacity to meet your project's demands efficiently.

What factors should be considered when purchasing a concrete batching plant?

When buying a concrete batching plant, consider factors like production capacity, automation level, mixing technology, mobility, environmental impact, and cost. These factors will influence the plant's operational efficiency and overall cost-effectiveness.

How do mobile and stationary concrete batching plants differ?

Mobile batching plants offer flexibility and ease of transport, ideal for projects requiring frequent relocation. In contrast, stationary plants are suited for high-volume production at a fixed location, offering greater production capacity and efficiency.

Who are the leading suppliers of concrete batching plants in Australia?

Top suppliers include ZOOMJO, Boral Australia, Holcim Australia, Batchcrete International, and Concrete Equipment Suppliers Australia. They are known for providing reliable and high-quality equipment.

What are the maintenance tips for prolonging the lifespan of concrete batching plants?

To extend the lifespan of your concrete batching plant, perform regular inspections and cleaning, ensure proper lubrication of moving parts, calibrate weighing systems, check electrical systems, and maintain a structured maintenance schedule.

What are the future trends in the Australian concrete batching plant industry?

Future trends include the integration of advanced technologies, a focus on environmental sustainability, increased customization and flexibility, market growth, and addressing industry challenges through innovative solutions.

How do environmental considerations impact the choice of a concrete batching plant?

Environmental considerations are increasingly important. Look for batching plants with features that reduce dust emissions, minimize noise pollution, and promote efficient energy use to meet sustainability goals.

What are the cost considerations for concrete batching plants in Australia?

The cost of concrete batching plants varies based on type, capacity, and technology. Consider the initial investment, long-term savings, and the potential benefits of new versus used equipment to make an informed decision.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська