The 6 common types of concrete batching plants

Concrete mixing plants are mechanical equipment designed to efficiently mix large quantities of concrete. They are widely used in large-scale construction projects for their ability to quickly mix the required concrete in precise proportions, dramatically improving construction efficiency, reducing material waste and saving costs. Depending on the needs of different projects, there are various types of concrete mixing plants to meet different construction requirements.

Six common types of concrete mixing plant

According to different designs and functions, concrete mixing plants can be categorised into the following six common types:

Stationary Concrete Batching Plant

A stationary concrete mixing plant is a large-scale concrete production equipment permanently installed in a specific location, designed for large-scale production. It is available in a variety of configurations and batch capacities, and typically includes equipment such as mixers, aggregate silos, cement silos and conveyor belts, and is equipped with a complete automated control system to ensure production stability and efficiency. The mixing plant is usually powered by electricity and can be connected to a water source to ensure water supply during the mixing process. Stationary batching plants are particularly suitable for long-term large-scale projects or scenarios where concrete is required on an ongoing basis.

Stationary concrete batching plants are available in capacities of 60, 90, 120, 180 and 240 m³/h. Depending on the customer's specific needs and capacity requirements, a batching plant can be equipped with two twin-shaft concrete mixers at the same time to meet higher production rates.

Mobile Batching Plant

A mobile batching plant is a portable concrete production plant that can be moved from one location to another as required. It includes all the ingredients needed to produce concrete, such as aggregates, water, cement and admixtures. This type of mixing plant is usually mounted on a trailer or other mobile platform and is capable of producing standard or customised concrete mixtures depending on the needs of the project. The output range of a mobile concrete batching plant is usually between 25 cubic metres and 120 cubic metres per hour.

Why choose a mobile concrete batching plant?

Mobile concrete batching plants are chosen for their quick and easy installation (only 1-2 days), cost-effective transport and easy relocation capabilities. In addition, mobile batching plants have minimal infrastructure costs and require no special installation permits, making them a flexible and efficient solution for concrete production.

Foundationless Concrete Batching Plant

A foundationless concrete plant is a compact and mobile concrete production plant that usually requires no special concrete foundation and can be installed on a level surface. These plants are suitable for short-term construction projects and can be quickly started up and dismantled for easy transfer between sites. Advantages include short set-up times, low transport costs, ease of operation and efficient production capacity. Foundationless mixing plants are typically used for projects such as roads, railways, bridges and water conservancies to meet temporary concrete needs.

Features of foundationless concrete mixing plant

Foundationless concrete mixing plant has the following main features:

1. quick installation: this mixing plant does not need a deep foundation, just harden the ground, which greatly shortens the installation time and can usually be deployed in a short time.

2. Stable structure: Adopting frame-type structure, all equipment parts are placed on the thick steel chassis, which enhances the stability and force area of the equipment.

3. Convenient relocation: The foundationless design makes it easy to disassemble and relocate the equipment, which is suitable for quick transfer between different sites.

4. Low foundation cost: Since no complicated foundation construction is required, customers can save a lot of time and cost for building the station.

5. Efficient production: the plant composition is similar to the traditional mixing plant, with a complete automated control system to ensure production efficiency and concrete quality.

6. Flexible Configuration: According to the customer's site conditions, different non-standard forms of mixing plant can be designed to meet specific needs.

7. Simplified transport: the electrical system adopts the form of quick-plug connector, which reduces the installation cycle of the equipment and makes transport and management more convenient.

Foundationless concrete mixing plant is very suitable for temporary projects, such as roads, railways, bridges and other projects, providing an efficient and flexible solution for construction.

Centralised Concrete Batching Plant

A centralised mixing plant is a device that concentrates all raw materials in one mixer for mixing, usually used for large-scale construction projects. It offers high productivity and consistent concrete quality, making it ideal for precast production and commercial concrete supply. In a centralised mixing plant, after all concrete components have been thoroughly mixed, the mixture is unloaded into mixer trucks and transported to the construction site. The station is equipped with stationary mixers (similar to silos) specifically designed to efficiently mix all ingredients, ensuring consistency and reliability of the final product.

Ready Mix Concrete Batching Plant

Ready Mixed Concrete (RMC) is concrete that is produced at the batching plant according to the requirements of each specific job and then transported to the construction site for immediate use. A Ready Mix Concrete Batching Plant is an efficient facility designed to mix raw materials such as cement, water, sand and aggregates to produce high quality ready mix concrete. The plant ensures consistency and reliability of the concrete through automated mixing processes, precise measurements and strict quality control.

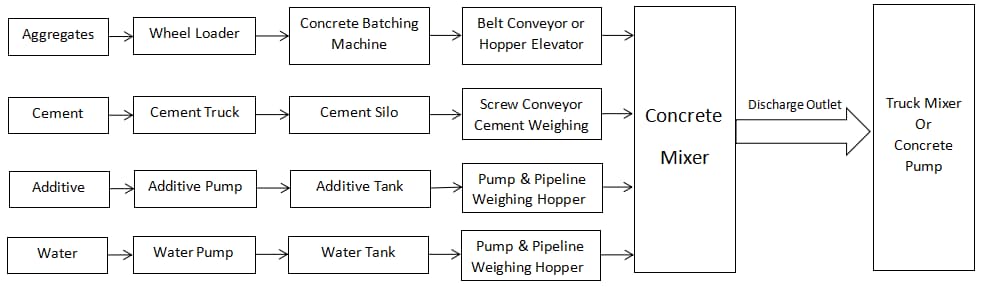

Main Components

Aggregate Handling System: Responsible for accurately weighing and batching aggregates to ensure consistent concrete quality.

Powder Storage System: Uses cement silos to store cement, fly ash and other materials for easy management and use.

Liquid Handling System: Includes tanks and additive pumps to accurately transfer liquids to the weighing system.

Mixer: a twin-shaft forced mixer is usually used to ensure that the raw materials are adequately mixed to achieve the desired concrete properties.

This highly efficient ready-mix concrete mixing plant is widely used in construction, road and infrastructure works, providing reliable concrete solutions for a variety of projects.

Dry Concrete Batching Plant

Dry concrete mixing plants mix aggregate materials (e.g. sand, gravel and cement) by precise metering. The mixture is unloaded into a mixer truck and combined with a certain amount of water and mixed during the journey to the construction site.

Difference between dry mixing plant and wet mixing plant?

Both dry and wet mixing plants are used to produce concrete, but there are significant differences between the two. A wet mixing plant is equipped with a twin shaft mixer and is capable of producing concrete on its own, whereas a dry mixing plant needs to be used in conjunction with a concrete mixer truck in order to complete the production of concrete for the needs of a construction project.

Each of these types of mixing plant has its own characteristics and can meet different scales and requirements of construction projects, which is an important and indispensable equipment for the modern construction industry.

Comparison of advantages and disadvantages of different types of concrete mixing plants

| Type | Advantages | Disadvantages | Applicable Scope |

|---|---|---|---|

| Centralized | High production efficiency, stable quality | Large area required, higher investment | Large-scale construction projects, precast component production |

| Ready-mixed | Quality assured, convenient for construction | Higher cost | Large-scale construction projects, municipal engineering |

| Dry mix | Reduced water evaporation, stable quality | Requires on-site water mixing | Projects with limited construction site space |

| Mobile | High flexibility, small footprint | Limited production capacity | Medium and small-scale construction projects, temporary projects |

| Stationary | Large production capacity, fully equipped | Poor flexibility | Large-scale construction projects, commercial concrete production |

| Continuous | High production efficiency | Higher investment | Large-scale concrete production projects |

How does the choice of mixing plant affect the quality of the project?

In construction projects, the quality of concrete is directly related to the overall quality and safety of the project. Therefore, choosing the right concrete mixing plant is crucial. Below are a few key factors that influence the choice of mixing plant on the quality of the project.

1. Production capacity and project requirements

When selecting a mixing plant, the first thing to consider is the specific needs of the project, including the quantity and type of concrete required. If the production capacity of the mixing plant is insufficient, it will result in insufficient supply of concrete, which will affect the construction progress and quality. On the contrary, excessive production capacity may result in wastage of resources.

2. Concrete consistency and quality control

Different types of mixing plants use different technologies and equipment in the concrete production process, which directly affect the uniformity and quality of concrete. For example, a modern automated mixing plant ensures accuracy in the batching and mixing process, thus improving the consistency and quality of concrete. If a mixing plant with outdated technology is chosen, it may lead to unstable concrete performance and affect project safety.

3. Quality of raw materials

The quality of raw materials used in the mixing plant directly affects the performance of the final concrete. When choosing a mixing plant, it should be ensured that it has good raw material procurement channels and strict quality control mechanism. Quality raw materials not only improve the strength of concrete, but also enhance its durability and crack resistance.

4. Management and control mechanism

Effective management and monitoring mechanism is an important guarantee of concrete quality. Choosing a mixing plant with a sound management system and a professional quality inspection team can monitor the whole production process and ensure that every step meets the standards. On the contrary, poor management may lead to frequent concrete quality problems, and even cause safety hazards.

5. Environmental and transport factors

The location, environmental conditions and accessibility of the mixing plant will also affect the quality of the project. If the mixing plant is too far away from the construction site, it may increase the transport time and cost, and also increase the risk of loss of concrete during transport. Therefore, a reasonable choice of the location of the mixing plant is essential to ensure construction efficiency and concrete quality.

In summary, the choice of mixing plant has a profound impact on the quality of construction projects. By comprehensively considering the production capacity, technical level, quality of raw materials, management mechanism and environmental factors, the overall quality of concrete can be effectively improved to provide a solid guarantee for the project. Therefore, a suitable concrete mixing plant should be carefully evaluated and selected at the early stage of the project to ensure the smooth progress of the project.

Conclusion

Different types of concrete mixing plants have their own advantages and adapt to the production needs of different projects. Whether it is a large-scale commercial building, infrastructure project, or a construction site that requires a high degree of flexibility, the right type of concrete mixing plant can significantly improve construction efficiency, ensure concrete quality, and save time and costs. As construction technology continues to advance, the use of concrete batching plants is becoming more widespread and important.

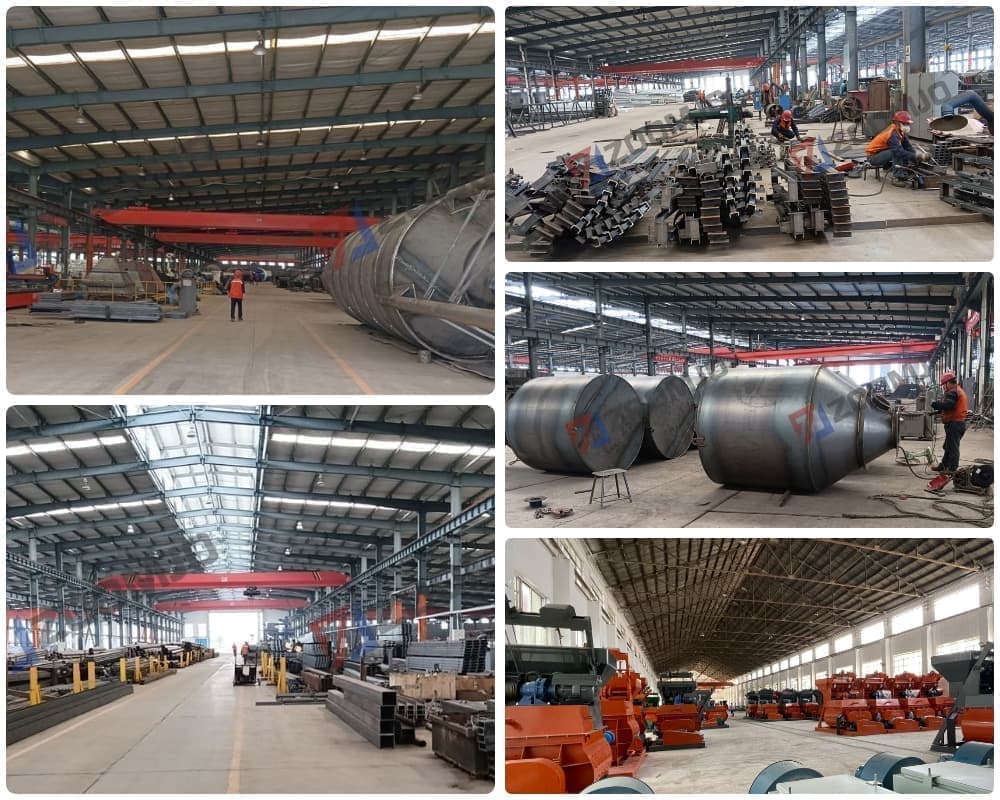

If you would like to know more about concrete batching plants and get a detailed quotation, please contact ZOOMJO, a renowned manufacturer in China, and we will provide you with professional advice and support to meet your specific needs.

English

English  Español

Español  简体中文

简体中文  Pусский

Pусский  українська

українська